Abstract

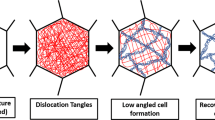

In the present work, different combinations of rolling used by the researchers as a novel severe plastic deformation technique for the deformation of Al–Mg–Si alloys have been investigated. Reported research work is used for explaining the microstructures obtained after the processing with the help of Electron Back-Scattered Diffraction (EBSD), Transmission Electron Microscopy (TEM) and Differential Scanning Calorimetery (DSC). Based on the literatures investigated, it was found that cryorolling (CR) followed by warm rolling (WR) of Al–Mg–Si alloy provided the highest specific strength compared to all the investigated different combinations of rolling techniques available in the open literatures. The CR (70%) followed by WR (20%) at 145 °C followed by ageing at 125 °C for 60 h provided the highest hardness (130 HV) and ultimate tensile strength (400 MPa) in Al–Mg–Si alloy having a chemical composition of (Si:0.67 Fe:0.28 Cu:0.20 Mn:0.04 Mg:1.01 Cr:0.05 Zn:0.06 Ti:0.01 Al: balance). The CR followed by warm rolling helped in retaining the higher strength as well as higher ductility. It is because of dynamic recovery and precipitation evolution was dominated during the processing. The dynamic recovery was promoted the higher ductility, and precipitation evolution helped in the improvement in the strength due to precipitation strengthening. The peak ageing of warm rolled sample further helped in improvement in the mechanical properties by evolution of β′′-precipitates.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

A. Azushima, R. Kopp, A. Korhonen, D.Y. Yang, F. Micari, G.D. Lahoti, A. Yanagida, Severe plastic deformation (SPD) processes for metals. CIRP Ann.57(2), 716–735 (2008)

M. Vaseghi, H.S. Kim, A combination of severe plastic deformation and ageing phenomena in Al–Mg–Si Alloys. Mater Des. 1980–2015(36), 735–740 (2012)

S.K. Panigrahi, R. Jayaganthana, V. Pancholi, M. Gupta, A DSC study on the precipitation kinetics of cryorolled Al 6063 alloy. Mater Chem Phys. 122, 188–193 (2010)

A.S.M. Agena, A study of flow characteristics of nanostructured Al-6082 alloy produced by ECAP under upsetting test. J Mater Process Technol. 209(2), 856–863 (2009)

S. Lokesh Vendra, S. Goel, R. Nikhil Kumar, Jayaganthan., A study on fracture toughness and strain rate sensitivity of severely deformed Al 6063 alloys processed by multiaxial forging and rolling at cryogenic temperature. Mater Sci Eng A. 686, 82–92 (2017)

S.K. Panigrahi, R. Jayaganthan, A study on the mechanical properties of cryorolled Al–Mg–Si alloy. Mater Sci Eng A. 480, 299–305 (2008)

N. Kumar, G.M. Owolabi, R. Jayaganthan, Al 6082 alloy strengthening through low strain multi-axial forging. Mater. Charact. 155, 109761 (2019)

B. Mirzakhani, Y. Payandeh, Combination of sever plastic deformation and precipitation hardening processes affecting the mechanical properties in Al–Mg–Si alloy. Mater Des. 68, 127–133 (2015)

A. Johannes, osterreicher., Combined cyclic deformation and artificial ageing of an Al–Mg–Si alloy. Mater Lett: X. 10, 100072 (2021)

M. Kolar, K.O. Pedersen, S. Gulbrandsen-Dahl, K. Marthinsen, Combined effect of deformation and artificial aging on mechanical properties of Al–Mg–Si Alloy. Trans Nonferrous Met Soc China. 22(8), 1824–1830 (2012)

A.P. Murugesan, V. Rajinikanth, B. Mahato, M. Wegner, M. Witte, G. Wilde, S.G. Chowdhury, Concurrent precipitation and associated texture evolution in AA 6082 alloy during high pressure torsion (HPT) processing. Mater Sci Eng: A. 700, 487–494 (2017)

X. Fan, Z. He, X. Knag, S. Yuan, Deformation and strengthening analysis of Al–Mg–Si alloy sheet during hot gas forming with synchronous die quenching. J Manuf Process. 57, 452–461 (2020)

Y.N. Kwon, Y.S. Lee, J.H. Lee, Deformation behaviour of Al–Mg–Si alloy at the elevated temperature. J. Mater. Process. Technol. 187–188, 533–536 (2007)

S.K. Panigrahi, R. Jayaganthan, Development of ultrafine grained Al–Mg–Si alloy with enhanced strength and ductility. J Alloys Compd. 470, 285–288 (2009)

S.K. Panigrahi, R. Jayaganthan, Development of ultrafine-grained Al 6063 alloy by cryorolling with the optimized initial heat treatment conditions. Mater Des. 32, 2172–2180 (2011)

M. Liu, H.J. Roven, Yu. Yingda, J.C. Werenskiold, Deformation structures in 6082 aluminium alloy after severe plastic deformation by equal-channel angular pressing. Mater. Sci. Eng., A. 483–484, 59–63 (2008)

H.J. Roven, M. Liu, J.C. Werenskiold, Dynamic precipitation during severe plastic deformation of an Al–Mg–Si Al alloy. Mater. Sci. Eng., A. 483–484, 54–58 (2008)

Y. Weng, Z. Jia, L. Ding, Y. Pan, Y. Liu, Q. Liu, Effect of Ag and Cu additions on natural aging and precipitation hardening behavior in Al–Mg–Si alloys. J Alloys Compd. 695, 2444–2452 (2017)

G. Das, M. Das, S. Ghosh, A.K. Paritosh Dubey, Ray., Effect of aging on mechanical properties of 6063 Al-alloy using instrumented ball indentation technique. Mater Sci Eng A. 527, 1590–1594 (2010)

T. Ye, L. Li, P. Guo, G. Xiao, Z. Chen, Effect of aging treatment on the microstructure and flow behavior of 6063 aluminum alloy compressed over a wide range of strain rate. Int. J. Impact Eng. 90, 72–80 (2016)

D. Odoh, Y. Mahmoodkhani, M. Wells, Effect of alloy composition on hot deformation behavior of some Al–Mg–Si alloys. Vacuum. 149, 248–255 (2018)

N. Kumar, P.N. Rao, R. Jayaganthan, H.G. Brokmeier, Effect of cryorolling and annealing on recovery, recrystallisation, grain growth and their influence on mechanical and corrosion behaviour of 6082 Al alloy. Mater chem phys. 165, 177–187 (2015)

P. Nageswera Rao, B. Viswanadh, R. Jayaganthan, Effect of cryorolling and warm rolling on precipitation evolution in Al 6061 alloy. Mater Sci Eng A. 606, 1–10 (2014)

S.K. Panigrahi, R. Jayaganthan, V. Chawla, Effect of cryorolling on microstructure of Al–Mg–Si alloy. Mater Lett. 62, 2626–2629 (2008)

H.W. Yang, I.P. Widiantara, Y.G. Ko, Effect of deformation path on texture and tension properties of submicrocrystalline Al–Mg–Si alloy fabricated by differential speed rolling. Materials Letter. 213, 54–57 (2018)

R. Nikhil Kumar, H.-G. Jayaganthan, Effect of deformation temperature on precipitation, microstructural evolution, mechanical and corrosion behavior of 6082 Al alloy. Trans. Nonferrous Met. Soc. China. 27, 475–492 (2017)

N. Kumar, R. Sunkulp Goel, H.B. Jayaganthan, Effect of grain boundary misorientaton, deformation temperature and AlFeMnSi-phase on fatigue life of 6082 Al alloy. Mater Charact. 124, 229–240 (2017)

O. Engler, C.D. Marioara, Y. Aruga, M. Kozuka, O.R. Myhr, Effect of natural ageing or pre-ageing on the evolution of precipitate structure and strength during age hardening of Al–Mg–Si alloy AA 6016. Mater. Sci. Eng., A. 759, 520–529 (2019)

S.K. Panigrahi, R. Jayaganthan, V. Pancholi, Effect of plastic deformation conditions on microstructural characteristics and mechanical properties of Al 6063 alloy. Mater Des. 30, 1894–1901 (2009)

D. Singh, R. Jayaganthan, Effect of post cryorolling treatments on microstructural and mechanical behaviour of ultrafine grained Al–Mg–Si alloy. J Mater Sci Technol. 30(10), 998–1005 (2014)

Y. Zi, L. Zeqin, D. Leyvraz, J. Banhart, Effect of pre-ageing on natural secondary ageing and paint bake hardening in Al–Mg–Si alloys. Materialia. 7, 100413 (2019)

S.K. Panigrahi, R. Jayaganthan, Effect of rolling temperature on microstructure and mechanical properties of 6063 Al alloy. Mater. Sci. Eng., A. 492, 300–305 (2008)

Lu et al., Effect of plastic deformation conditions on microstructural characteristics and mechanical properties of Al 6063 alloy-phase particle evolution in a twin-roll-casted Al-Mg-Si alloy on recrystallization texture and mechanical anisotropy. Mater. Charact. 176, 111038 (2021)

H. Zhao, Q. Pan, Q. Qin, Wu. Yujiao, Su. Xiangdong, Effect of the processing parameters of friction stir processing on the microstructure and mechanical properties of 6063 aluminum alloy. Mater. Sci. Eng., A. 751, 70–79 (2019)

Yu. Wang, Y. Deng, J. Chen, Q. Dai, X. Guo, Effects of grain structure related precipitation on corrosion behavior and corrosion fatigue property of Al–Mg–Si alloy. J. mater. Res. technol. 9(3), 5391–5540 (2020)

X. Qian, N. Parson, X. Grant Chen, Effects of Mn content on recrystallization resistance of AA6082 aluminum alloys during post-deformation annealing. J Mater Sci Technol. 52, 189–197 (2020)

P.R. Nageswara raoJayaganthan, Effects of warm rolling and ageing after cryogenic rolling on mechanical properties and microstructure of Al 6061 alloy. Mater Des. 39, 226–233 (2012)

M.J. Kim, M.G. Lee, K. Hariharan, S.T. Hong, I.S. Choi, D. Kim, H.N. Han, Electric current–assisted deformation behavior of Al–Mg–Si alloy under uniaxial tension. Int J Plast. 94, 148–170 (2017)

W.J. Kim, S.J. Yoo, Enhanced ductility and deformation mechanisms of ultrafine-grained Al–Mg–Si alloy in sheet form at warm temperatures. Scripta Mater. 61, 125–128 (2009)

K. Majchrowicz, Z. Pakiela, W. Chrominski, M. Kulczyk, Enhanced strength and electrical conductivity of ultrafine-grained Al–Mg–Si alloy processed by hydrostatic extrusion. Mater. Charact. 135, 104–114 (2018)

L. Winter, K. Hockauf, S. Winter, T. Lampke, Equal-channel angular pressing influencing the mean stress sensitivity in the high cycle fatigue regime of the 6082 aluminum alloy. Mater. Sci. Eng., A. 795, 140014 (2020)

E. Ortiz-cuellar, M.A.L. Hernandez-Rodriguez, E. Garcia-Sanchez, Evaluation of the tribological properties of an Al–Mg–Si alloy processed by severe plastic deformation. Wear. 271, 1828–1832 (2011)

O.P. Gbenebor, O.S.I. Fayomi, A.P.I. Popoola, A.O. Inegbenebor, F. Oyawale, Extrusion die geometry effects on the energy absorbing properties and deformation response of 6063-type Al–Mg–Si aluminum alloy. Results in Physics. 3, 1–6 (2013)

D.C.C. Magalhaes, A.M. Kliauga, V.L. Sordi, Flow behavior and fracture of Al–Mg–Si alloy at cryogenic temperatures. Trans. Nonferrous Met. Soc. China. 31, 595–608 (2021)

Q.Y. Yang, Y.A.N.G. Dong, Z.Q. Zhang, L.F. Cao, X.D. Wu, G.J. Huang, L.I.U. Qing, Flow behavior and microstructure evolution of 6A82 aluminium alloy with high copper content during hot compression deformation at elevated temperatures. Transact Nonferrous Met Soc China. 26(3), 649–657 (2016)

Y. Aruga, M. Kozuka, T. Sato, Formulation of initial artificial age-hardening response in an Al–Mg–Si alloy based on the cluster classification using a high-detection-efficiency atom probe. J. Alloy. Compd. 739, 1115–1123 (2018)

D. Pan, Y. Wang, Q. Guo, D. Zhang, X. Xu, Y. Zhao, Grain refinement of Al–Mg–Si alloy without any mechanical deformation and matrix phase transformation via cyclic electro-pulsing treatment. Mater Sci Eng: A. 807, 140916 (2021)

S.H. Wang, C.H. Liu, J.H. Chen, X.L. Li, D.H. Zhu, G.H. Tao, Hierarchical nanostructures strengthen Al–Mg–Si alloys processed by deformation and aging. Mater Sci Eng: A. 585, 233–242 (2013)

L. Winter, K. Hockau, T. Lampke, High cycle fatigue behavior of the severely plastically deformed 6082 aluminum alloy with an anodic and plasma electrolytic oxide coating. Surf. Coat. Technol. 349, 576–658 (2018)

J. Li, X. Wu, L. Cao, B. Liao, Y. Wang, Q. Liu, Hot deformation and dynamic recrystallization in Al–Mg–Si alloy. Mater Charact. 173, 110976 (2021)

H. Liao, Wu. Yuna, K. Zhou, J. Yang, Hot deformation behavior and processing map of Al-Si-Mg alloys containing different amount of silicon based on Gleebe-3500 hot compression simulation. Mater. Des. 65, 1091–1099 (2015)

Hu. Jiamin, W. Zhang, Fu. Dingfa, J. Teng, H. Zhang, Improvement of the mechanical properties of Al–Mg–Si alloys with nano-scale precipitates after repetitive continuous extrusion forming and T8 tempering. J Mater Res Technol. 8(6), 5950–5960 (2019)

J. Zhang, M. Ma, F. Shen, D. Yi, B. Wang, Influence of deformation and annealing on electrical conductivity, mechanical properties and texture of Al–Mg–Si alloy cables. Mater Sci Eng: A. 710, 27–37 (2018)

J. González, S. Bagherifard, M. Guagliano, I.F. Pariente, Influence of different shot peening treatments on surface state and fatigue behaviour of Al 6063 alloy. Eng Fract Mech. 185, 72–81 (2017)

G.J. Gao, H.E. Chen, L.I. Yong, J.D. Li, Z.D. Wang, R.D.K. Misra, Influence of different solution methods on microstructure, precipitation behavior and mechanical properties of Al–Mg–Si alloy. Trans Nonferrous Met Soci China. 28(5), 839–847 (2018)

D. Jiang, C. Wang, Influence of microstructure on deformation behaviour and fracture mode of Al–Mg–Si alloy. Mater. Sci. Eng., A. 352, 29–33 (2003)

E. Cerri, P. Leo, Influence of severe plastic deformation on aging of Al–Mg–Si alloys. Mater. Sci. Eng., A. 410–411, 226–229 (2005)

M. Hussain, P.N. Rao, D. Singh, R. Jayaganthan, S. Goel, K.K. Saxena, Insight to the evolution of nano precipitates by cryo rolling plus warm rolling and their effect on mechanical properties in Al 6061 alloy. Mater Sci Eng: A. 811, 141072 (2021)

V. Kumar, D. Kumar, Investigation of tensile behaviour of cryorolled and room temperature rolled 6082 Al alloy. Mater. Sci. Eng., A. 691, 211–217 (2017)

J. Bouquerel, B. Diawara, A. Dubois, M. Dubar, J.-B. Vogt, D. Najjar, Investigations of the microstructural response to a cold forging process of the 6082–T6 alloy. Mater. Des. 68, 245–258 (2015)

N.R. Bochvar, O.V. Rybalchenko, N.Y. Tabachkova, G.V. Rybalchenko, N.P. Leonova, L.L. Rokhlin, Kinetics of phase precipitation in Al–Mg–Si alloys subjected to equal-channel angular pressing during subsequent heating. J Alloys Compd. 881, 160583 (2021)

P.N. Rao, D. Singh, R. Jayaganthan, Mechanical properties and microstructural evolution of Al 6061 alloy processed by multidirectional forging at liquid nitrogen temperature. Mater Des. 56, 97–104 (2014)

L. Wan, Y. Huang, W. Guo, S. Lv, J. Feng, Mechanical Properties and Microstructure of 6082–T6 Aluminum Alloy Joints by Self-support Friction Stir Welding. J. Mater. Sci. Technol. 30(12), 1243–1250 (2014)

X. Zhang, L.K. Huang, B. Zhang, Y.Z. Chen, F. Liu, Microstructural evolution and strengthening mechanism of an Al–Si–Mg alloy processed by high-pressure torsion with different heat treatments. Mater Sci Eng: A. 794, 139932 (2020)

M. Song, J. Kim, Microstructural evolution at the initial stage of two-step aging in an Al–Mg–Si alloy characterized by a three dimensional atom probe. Mater Sci Eng: A. 815, 141301 (2021)

X.D. Wang, L.I.U. Xiong, D.I.N.G. Hao, S.R. Yan, Z.H. Xie, B.Q. Pan, W.Y. Wang, Microstructure and mechanical properties of Al− Mg− Si alloy U-shaped profile. Trans Nonferrous Met Soc China. 30(11), 2915–2926 (2020)

Liu et al., Microstructure and mechanical properties of Al–Mg–Si alloy fabricated by a short process based on sub-rapid solidification. J Mater Sci Technol. 41, 178–186 (2020)

K.J. Al-Fadhalah, A.I. Almazrouee, A.S. Aloraier, Microstructure and mechanical properties of multi-pass friction stir processed aluminum alloy 6063. Mater. Des. 53, 550–560 (2014)

X. Meng, S. Yang, Yu. Yubao Huang, J.G. Fang, Qi. Xiong, C. Duan, Microstructure characterization and mechanism of fatigue crack propagation of 6082 aluminum alloy joints. Mater. Chem. Phys. 257, 123734 (2021)

S. Liu, Q. Pan, M. Li, X. Wang, X. He, X. Li, J. Lai, Microstructure evolution and physical-based diffusion constitutive analysis of Al–Mg–Si alloy during hot deformation. Mater Des. 184, 108181 (2019)

R. Lu, S. Zheng, J. Teng, J. Hu, D. Fu, J. Chen, H. Zhang, Microstructure, mechanical properties and deformation characteristics of Al–Mg–Si alloys processed by a continuous expansion extrusion approach. J Mater Sci Technol. 80, 150–162 (2021)

M. Liu, J. Chen, Y. Lin, Z. Xue, H.J. Roven, P.C. Skaret, Microstructure, mechanical properties and wear resistance of an Al–Mg–Si alloy produced by equal channel angular pressing. Prog Nat Sci: Mater Int. 30(4), 485–493 (2020)

M. Shakoori Oskooie, H. Asgharzadeh, H.S. Kim, Microstructure, plastic deformation and strengthening mechanisms of an Al–Mg–Si alloy with a bimodal grain structure. J alloys an compound. 632, 540–5548 (2015)

S. Lin, Y.L. Deng, J.G. Tang, S.H. Deng, H.Q. Lin, L.Y. Ye, X.M. Zhang, Microstructures and fatigue behavior of metal-inert-gas-welded joints for extruded Al–Mg–Si alloy. Mater Sci Eng: A. 745, 63–73 (2019)

M. Das, G. Das, M. Ghosh, V. Matthias Wegner, S.G. Rajnikant, T.K.P. Chowdhury, Microstructures and mechanical properties of HPT processed 6063 Al alloy. Mater Sci Eng A. 558, 525–532 (2012)

S.B. Puplampu, A. Siriruk, A. Sharma, D. Penumadu, Multiaxial deformation behavior of aluminum alloy 6061 subjected to fire damage. Mech. Mater. 159, 103885 (2021)

J.K. Sunde, C.D. Marioara, S. Wenner, R. Holmestad, On the microstructural origins of improvements in conductivity by heavy deformation and ageing of Al–Mg–Si alloy 6101. Mater Charact. 176, 111073 (2021)

N. Kumar, G.M. Owolabi, R. Jayaganthan, O.O. Ajide, Plane stress fracture toughness of cryorolled 6082 Al alloy. Theoret. Appl. Fract. Mech. 95, 28–41 (2018)

M. Yang, H. Chen, A. Orekhov, Q. Lu, X. Lan, K. Li, Y. Du, Quantified contribution of β ″and β′ precipitates to the strengthening of an aged Al–Mg–Si alloy. Mater Sci Eng: A. 774, 138776 (2020)

J.-H. Zheng, C. Pruncu, K. Zhang, K. Zheng, J. Jiang, Quantifying geometrically necessary dislocation density during hot deformation in AA6082 Al alloy. Mater. Sci. Eng., A. 814, 141158 (2021)

H. Ma, Q. Hou, Yu. Zhiwei, P. Ni, Stability of 6082–T6 aluminum alloy columns under axial forces at high temperatures. Thin-Walled Struct. 157, 107083 (2020)

S. Dadbakhsh, A. Karimi Taheri, C.W. Smith, Strengthening study on 6082 Al alloy after combination of aging treatment and ECAP process. Mater Sci Eng A. 527, 4758–4766 (2010)

Y.X. Lai, W. Fan, M.J. Yin, C.L. Wu, J.H. Chena, Structures and formation mechanisms of dislocation-induced precipitates in relation to the age-hardening responses of Al–Mg–Si alloys. J. Mater. Sci. Technol. 41, 127–138 (2020)

Wang et al., Superior mechanical properties induced by the interaction between dislocations and precipitates in the electro-pulsing treated Al–Mg–Si alloys. Mater. Sci. Eng., A. 735, 154–161 (2018)

L. Shi, K. Baker, R. Young, J. Kang, J. Liang, B. Shalchi-Amirkhiz, H. Zurob, The effect of chemical patterning induced by cyclic plasticity on the formation of precipitates during aging of an Al–Mg–Si alloy. Mater Sci Eng: A. 815, 141265 (2021)

Teichmann et. al., The effect of simultaneous deformation and annealing on the precipitation behaviour and mechanical properties of an Al–Mg–Si alloy Mater. Sci. Eng., A 565, 228–235 (2013)

T. Saito, C.D. Marioara, J. Røyset, K. Marthinsen, R. Holmestad, The effects of quench rate and pre-deformation on precipitation hardening in Al–Mg–Si alloys with different Cu amounts. Mater Sci Eng: A. 609, 72–79 (2014)

N. Kumar, S. Goel, R. Jayaganthan, G.M. Owolabi, The influence of metallurgical factors on low cycle fatigue behavior of ultra-fine grained 6082 Al alloy. Int. J. Fatigue. 110, 130–143 (2018)

M.M. El-Rayes, E.A. El-Danaf, The influence of multi-pass friction stir processing on the microstructural and mechanical properties of Aluminum Alloy 6082. J Mater Process Technol. 212(5), 1157–1168 (2012)

Kim et al., The nanocluster formation and vacancy behavior of step-quenched Al–Mg–Si alloy and its effect on transition to β′′-phase via advanced methods. Mater. Sci. Eng., A. 811, 141032 (2021)

A. Biradar, R. Rasiwasia, J. Soni, M. Orłowska, M. Rijesh, Thermomechanical roll bonding of Al-6063 strips. J Alloys Compd. 855, 157401 (2021)

Y. Birol, Thixoforging experiments with 6082 extrusion feedstock. J alloy Compd. 455, 178–185 (2008)

H. Mao, Y. Kong, D. Cai, M. Yang, Y. Peng, Y. Zeng, Y. Du, β’’needle-shape precipitate formation in Al–Mg–Si alloy: Phase field simulation and experimental verification. Comput Mater Sci. 184, 109878 (2020)

N. Kumar, An exploration of microstructural in-homogeneity in the 6082 Al alloy processed through room temperature multi-axial forging. Mater. Charact. 176, 111134 (2021)

N. Kumar, G.M. Owolabi, R. Jayaganthan, S. Goel, Correlation of fracture toughness with microstructural features for ultrafine-grained 6082 Al alloy. Fatigue Fract Eng Mater Struct. 41(9), 1884–1899 (2018)

N. Kumar, G.M. Owolabi, R. Jayaganthan, G. Warner, Effect of Annealing on Mechanical Properties and Metallurgical Factors of Ultrafine-Grained 6082 Al Alloy. Trans Indian Inst Met. 72(9), 2523–2531 (2019)

N. Kumar, G.M. Owolabi, R. Jayaganthan, O.O. Ajide, S. Sonker, G. Warner, Hot-Compression Response of Solution-Treated Al–Mg–Si Alloy. J. of Materi Eng and Perform. 28, 7602–7615 (2019)

S.P. Yuan, G. Liu, R.H. Wang, G.-J. Zhang, X. Pu, J. Sun, K.-H. Chen, Effect of precipitate morphology evolution on the strength–toughness relationship in Al–Mg–Si alloys. Scripta Mater. 60, 1109–1112 (2009)

R.S. Yassar, D.P. Field, H. Weiland, The effect of pre-deformation on the β’’ and β’ precipitates and the role of Q’ phase in an Al–Mg–Si alloy; AA6022. Scripta Mater. 53, 299–303 (2005)

D.J. Lloyd, D. Steele, J.H. Huang, Plasticity associated with grain boundaries during the bending of an Al–Mg–Si-based alloy. Scripta Mater. 63, 426–429 (2010)

Y. Birol, Pre-straining to improve the bake hardening response of a twin-roll cast Al–Mg–Si alloy. Scripta Mater. 52, 169–173 (2005)

S. de La Chapelle, Cube recrystallization textures in a hot deformed Al–Mg–Si alloy. Scripta Mater. 45, 1387–1391 (2001)

I. Sabirov, M.R. Barnett, Y. Estrin, P.D. Hodgson, The effect of strain rate on the deformation mechanisms and the strain rate sensitivity of an ultra-fine-grained Al alloy. Scripta Mater. 61, 181–184 (2009)

M.A. van Huis, J.H. Chen, M.H.F. Sluiter, H.W. Zandbergen, Phase stability and structural features of matrix-embedded hardening precipitates in Al–Mg–Si alloys in the early stages of evolution. Acta Mater. 55, 2183–2199 (2007)

S. Pogatscher, H. Antrekowitsch, H. Leitner, T. Ebner, P.J. Uggowitzer, Mechanisms controlling the artificial aging of Al–Mg–Si Alloys. Acta Mater. 59, 3352–3363 (2011)

P.H. Ninive, A. Strandlie, S. Gulbrandsen-Dahl, W. Lefebvre, C.D. Marioara, S.J. Andersen, O.M. Løvvik, Detailed atomistic insight into the β ″phase in Al–Mg–Si alloys. Acta mater. 69, 126–134 (2014)

M.J. Starink, L.F. Cao, P.A. Rometsch, A model for the thermodynamics of and strengthening due toco-clusters in Al–Mg–Si-based alloys. Acta Mater. 60, 4194–4207 (2012)

Sha et al., Strength, grain refinement and solute nanostructures of an Al–Mg–Si alloy (AA6060) processed by high-pressure torsion. Acta Mater. 63, 169–179 (2014)

Q. Du, K. Tang, C.D. Marioara, S.J. Andersen, B. Holmedal, R. Holmestad, Modeling over-ageing in Al–Mg–Si alloys by a multi-phase CALPHAD-coupled Kampmann-Wagner Numerical model. Acta Mater. 122, 178–186 (2017)

X. Sauvage, E.V. Bobruk, MYu. Murashkin, Y. Nasedkina, N.A. Enikeev, R.Z. Valiev, Optimization of electrical conductivity and strength combination by structure design at the nanoscale in Al–Mg–Si alloys. Acta Mater. 98, 355–366 (2015)

W. Chrominski, M. Lewandowska, Precipitation phenomena in ultrafine grained Al–Mg–Si alloy with heterogeneous microstructure. Acta Mater. 103, 547–557 (2016)

S. Zhu, H.-C. Shih, X. Cui, Yu. Chung-Yi, S.P. Ringer, Design of solute clustering during thermomechanical processing of AA6016 Al–Mg–Si alloy. Acta Mater. 203, 116455 (2021)

P.W.J. Mckenzie, R. Lapovok, Y. Estrin, The influence of back pressure on ECAP processed AA 6016: Modeling and experiment. Acta Mater. 55, 2985–2993 (2007)

S. Jana, R.S. Mishra, J.B. Baumann, G. Grant, Effect of friction stir processing on fatigue behavior of an investment cast Al–7Si–0.6 Mg alloy. Acta Mater. 58, 989–1003 (2010)

S. Zhang, P.G. Mccormick, Y. Estrin, The morphology of portevin–le chatelier bands: finite element simulation for Al–Mg–Si. Acta mater. 49, 1087–1094 (2001)

D. Giofre, W.A. Till Junge, M.C. Curtin, Ab initio modelling of the early stages of precipitation in Al-6000 alloys. Acta Mater. 140, 240–249 (2017)

E. Mariani, E. Ghassemieh, Microstructure evolution of 6061 O Al alloy during ultrasonic consolidation: An insight from electron backscatter diffraction. Acta Mater. 58, 2492–2503 (2010)

S. Shimizu, H.T. Fujii, Y.S. Sato, H. Kokawa, M.R. Sriraman, S.S. Babu, Mechanism of weld formation during very-high-power ultrasonic additive manufacturing of Al alloy 6061. Acta Mater. 74, 234–243 (2014)

P.W.J. Mckenzie, R. Lapovok, ECAP with back pressure for optimum strength and ductility in aluminium alloy 6016. Part 1: Microstructure. Acta Mater. 58, 3198–3211 (2010)

W. Woo, H. Choo, D.W. Brown, S.C. Vogel, P.K. Liaw, Z. Feng, Texture analysis of a friction stir processed 6061–T6 aluminum alloy using neutron diffraction. Acta Mater. 54, 3871–3882 (2006)

F. Hannard, T. Pardoen, E. Maire, C. Le Bourlot, R. Mokso, A. Simar, Characterization and micromechanical modelling of microstructural heterogeneity effects on ductile fracture of 6xxx aluminium alloys. Acta Mater. 103, 558–572 (2016)

P.W.J. Mckenzie, R. Lapovok, ECAP with back pressure for optimum strength and ductility in aluminium alloy 6016. Part 2: Mechanical properties and texture. Acta Mater. 58, 3212–3222 (2010)

A. Simar, Y.B.A.T. Bre´chetde MeesterDenquinPardoen, Sequential modeling of local precipitation, strength and strain hardening in friction stir welds of an aluminum alloy 6005A–T6. Acta Mater. 55, 6133–6143 (2007)

T. Sritharan, R.S. Chandel, Phenomena in interrupted tensile tests of heat-treated aluminium alloy 6061. Acta Mater. 45(8), 3155–3161 (1997)

M. Ravi Shankar, S. Chandrasekar, A.H. King, W. Dale Compton, Microstructure and stability of nanocrystalline aluminum 6061 created by large strain machining. Acta Mater. 53, 4781–4793 (2005)

Acknowledgement

The author would like to acknowledge the financial support received under the scheme of seed grant provided to Dr. Nikhil Kumar by the IIT(BHU), Varanasi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

I have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, N. Severe Plastic Deformation of Al–Mg–Si Alloys Processed Through Rolling Techniques: A Review. Metallogr. Microstruct. Anal. 11, 353–404 (2022). https://doi.org/10.1007/s13632-022-00859-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-022-00859-6