Abstract

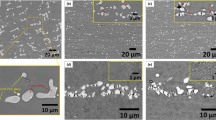

Superior strength-ductility synergy of 1045 carbon steel produced by aluminothermic reaction casting method was obtained through large deformation rolling at ambient temperature and subsequent annealing, meanwhile, a heterogeneous composite structure was fabricated. The heterogeneous structural 1045 carbon steel consists of “soft” microcrystalline/ultrafine grained (UFG) ferrite and “hard” cementite nanoparticles. The outstanding strength-ductility synergy was primarily attributed to the microstructure characteristics about the “soft/hard” interfaces of heterogeneous composite structure. The strength was improved due to the second phase reinforcement of hard cementite nanoparticles and decreasing of ferrite grain size, meanwhile, the back stress hardening capacity of “soft/hard” phase also resulted in the high strength. And the favorable ductility was ascribed to the generation of geometrically necessary dislocations (GNDs) around “soft/hard” interfaces, which resulted in the high work hardening capability of heterogeneous structural 1045 carbon steel. It is remarkable that tensile strength (∼ 1190 MPa) and high yield strength (∼ 1118 MPa) and good ductility (∼10.6%) can be simultaneously acquired for the cold rolled 1045 steel after annealing at 673 K for 1 h.

Graphic Abstract

Similar content being viewed by others

References

C. Zheng, L. Li, Mater. Sci. Eng. A. 713, 35 (2018)

F.M. Al-Abbasi, Mater. Sci. Eng. A. 527, 6904 (2010)

X. Zhang, N. Hansen, A. Godfrey et al., Acta. Metall. 114, 176 (2016)

Y. He, S. Xiang, W. Shi et al., Mater. Sci. Eng. A. 683, 153 (2017)

S. Ramtani, G. Dirras, H.Q. Bui, Mech. Mater. 42, 522 (2010)

Y.J. Li, P. Choi, C. Borchers et al., Acta. Metall. 59, 3965 (2011)

L. Zhou, F. Fang, X. Zhou et al., Scr. Mater. 120, 5 (2016)

E. Ma, T. Zhu, Mater. Today. 20, 323 (2017)

M.X. Yang, Y. Pan, F.P. Yuan, Y.T. Zhu, Wu XL. Mater. Res. Lett. 4, 145 (2016)

M. Yang, D. Yan, F. Yuan et al., P. Natl. Acad. Sci. USA 115, 7224 (2018)

Z.N. Li, F.A. Wei, P.Q. La, H.D. Wang, Y.P. Wei, Adv. Mater. Sci. Eng. 2017, 1 (2017)

Z.N. Li, F.A. Wei, P.Q. La, F.L. Ma, Met. Mater. Int. 24, 1 (2018)

C.W. Bang, J.B. Seol, Y.S. Yang et al., Scr. Mater. 108, 151 (2015)

G.A. Nematollahi, B. Grabowski, D. Raabe et al., Acta. Metall. 111, 321 (2016)

S. Chattopadhyay, C.M. Sellars, Acta Metall. 30, 157 (1982)

A.A. Gazder, S.S. Hazra, E.V. Pereloma, Mater. Sci. Eng. A. 530, 492 (2011)

L. Storojeva, D. Ponge, R. Kaspar et al., Acta Mater. 52, 2209 (2004)

C. Borchers, T. Al-Kassab, S. Goto et al., Mater. Sci. Eng. A. 502, 131 (2009)

P. Sathiyamoorthi, P. Asghari-Rad, J.M. Park et al., Mater. Sci. Eng. A. 766, 138372 (2019)

H.K. Park, K. Ameyama, J. Yoo et al., Materials Research Letters 6, 261 (2018)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (51561020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Z., La, P., Sheng, J. et al. Outstanding Synergy of Superior Strength and Ductility in Heterogeneous Structural 1045 Carbon Steel. Met. Mater. Int. 27, 2562–2574 (2021). https://doi.org/10.1007/s12540-020-00662-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00662-4