Abstract

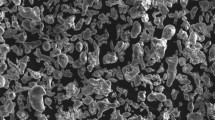

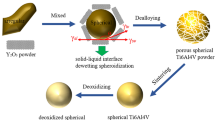

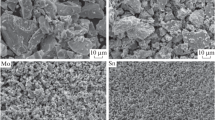

In this study, the Ti–6Al–4V alloy hollow spheres were prepared by powder metallurgy method under different sintering temperatures (1200 °C, 1250 °C, 1300 °C, 1350 °C and 1400 °C). And the density, shrinkage and microstructure of hollow spheres were tested by Archimedes drainage method, diameter measurement, optical microscope and scanning electron microscope, respectively. The results show that the density and shrinkage of hollow spheres increase gradually with the sintering temperature increasing, while the porosity of the shell of hollow spheres decreased along with the increase of sintering temperature. When the sintering temperature is 1400 °C, the hollow sphere has the largest density of 2.10 g/cm3, the largest shrinkage of 22.0% and the smallest porosity of 14.2%. By comparing the micro-morphology and properties under different temperatures, when the sintering process lasted for 180 min at 1400 °C, the Ti–6Al–4V hollow spheres have the smallest porosity and the largest density.

Graphic Abstract

Similar content being viewed by others

References

A. Rabiei, A.T. O’Neill, A study on processing of a composite metal foam via casting. Mater. Sci. Eng. A 404, 159–164 (2005). https://doi.org/10.1016/j.msea.2005.05.089

L.J. Vendra, A. Rabiei, A study on aluminum–steel composite metal foam processed by casting. Mater. Sci. Eng. A 465, 59–67 (2007). https://doi.org/10.1016/j.msea.2007.04.037

L.J. Vendra, A. Rabiei, N. Reese, N. Young, B.P. Neville, Processing and characterization of a new composite metal foam. Mater. Trans. 47, 2148–2153 (2006). https://doi.org/10.2320/matertrans.47.2148

B.P. Neville, A. Rabiei, Composite metal foams processed through powder metallurgy. Mater. Des. 29, 388–396 (2008). https://doi.org/10.1016/j.matdes.2007.01.026

A. Rabiei, L.J. Vendra, A comparison of composite metal foam's properties and other comparable metal foams. Mater. Lett. 63, 533–536 (2009). https://doi.org/10.1016/j.matlet.2008.11.002

H. Goehler, U. Jehring, J. Meinert, R. Hauser, Functionalized Metallic Hollow Sphere Structures. Adv. Eng. Mater. 16, 335–339 (2014). https://doi.org/10.1002/adem.201300057

J. Marx, A. Rabiei, Overview of composite metal foams and their properties and performance. Adv. Eng. Mater. 19, 1600776 (2017). https://doi.org/10.1002/adem.201600776

W.S. Sanders, L.J. Gibson, Mechanics of hollow sphere foams. Mater. Sci. Eng. A 347, 70–85 (2003). https://doi.org/10.1016/S0921-5093(02)00583-X

O. Friedl, C. Motz, H. Peterlik, S. Puchegger, N. Reger, R. Pippan, Experimental investigation of mechanical properties of metallic hollow sphere structures. Metall. Mater. Trans. B 39, 135–146 (2008). https://doi.org/10.1007/s11663-007-9098-2

M. Vesenjak, Z. Ren, T. Fiedler, A. Öchsner, Impact behavior of composite hollow sphere structures. J. Compos. Mater. 43, 2491–2505 (2009). https://doi.org/10.1177/0021998309094970

J.A. Brown, L.J. Vendra, A. Rabiei, Bending properties of Al–steel and steel–steel composite metal foams. Metall. Mater. Trans. A 41, 2784–2793 (2010). https://doi.org/10.1007/s11661-010-0343-y

L.J. Vendra, A. Rabiei, Evaluation of modulus of elasticity of composite metal foams by experimental and numerical techniques. Mater. Sci. Eng. A 527, 1784–1790 (2010). https://doi.org/10.1016/j.msea.2009.11.004

L.J. Vendra, J.A. Brown, A. Rabiei, Effect of processing parameters on the microstructure and mechanical properties of Al–steel composite foam. J. Mater. Sci. 46, 4574–4581 (2011). https://doi.org/10.1007/s10853-011-5356-4

A. Rabiei, M. Garcia-Avila, Effect of various parameters on properties of composite steel foams under variety of loading rates. Mater. Sci. Eng. A 564, 539–547 (2013). https://doi.org/10.1016/j.msea.2012.11.108

Y. Alvandi-Tabrizi, D.A. Whisler, H. Kim, A. Rabiei, High strain rate behavior of composite metal foams. Mater. Sci. Eng. A 631, 248–257 (2015). https://doi.org/10.1016/j.msea.2015.02.027

J. Marx, M. Portanova, A. Rabiei, A study on blast and fragment resistance of composite metal foams through experimental and modeling approaches. Compos. Struct. 194, 652–661 (2018). https://doi.org/10.1016/j.compstruct.2018.03.075

M. Garcia-Avila, M. Portanova, A. Rabiei, Ballistic performance of composite metal foams. Compos. Struct. 125, 202–211 (2015). https://doi.org/10.1016/j.compstruct.2015.01.031

S. Chen, J. Marx, A. Rabiei, Experimental and computational studies on the thermal behavior and fire retardant properties of composite metal foams. Int. J. Therm. Sci. 106, 70–79 (2016). https://doi.org/10.1016/j.ijthermalsci.2016.03.005

S. Chen, M. Bourham, A. Rabiei, Applications of open-cell and closed-cell metal foams for radiation shielding. Procedia Mater. Sci. 4, 293–298 (2014). https://doi.org/10.1016/j.mspro.2014.07.560

S. Chen, M. Bourham, A. Rabiei, Attenuation efficiency of X-ray and comparison to gamma ray and neutrons in composite metal foams. Radiat. Phys. Chem. 117, 12–22 (2015). https://doi.org/10.1016/j.radphyschem.2015.07.003

S. Chen, M. Bourham, A. Rabiei, Neutrons attenuation on composite metal foams and hybrid open-cell Al foam. Radiat. Phys. Chem. 109, 27–39 (2015). https://doi.org/10.1016/j.radphyschem.2014.11.003

O. Andersen, U. Waag, L. Schneider, G. Stephani, B. Kieback, Novel metallic hollow sphere structures. Adv. Eng. Mater. 2, 192–195 (2000). https://doi.org/10.1002/(SICI)1527-2648(200004)2:4%3c192:AID-ADEM192%3e3.0.CO;2-%23

C. Augustin, W. Hungerbach, Production of hollow spheres (HS) and hollow sphere structures (HSS). Mater. Lett. 63, 1109–1112 (2009). https://doi.org/10.1016/j.matlet.2009.01.015

M. Behnam, A.S. Golezani, M.M. Lima, Optimization of surface quality and shell porosity in low carbon steel hollow spheres produced by powder metallurgy. Powder Technol. 235, 1025–1029 (2013). https://doi.org/10.1016/j.powtec.2012.11.038

H.R. Davari, H. Gholamzadeh, S.A. Dehghan, M.H. Paydar, Effect of sintering parameters (time and temperature) upon the fabrication process of organic binder-based metallic hollow sphere. Powder Metall. 60, 1–8 (2017). https://doi.org/10.1080/00325899.2017.1355424

N.K. Gupta, G.L. Easwara Prasad, S.K. Gupta, Axial compression of metallic spherical shells between rigid plates. Thin Wall. Struct. 34, 21–41 (1999). https://doi.org/10.1016/S0263-8231(98)00049-4

M. Borovinšek, M. Vesenjak, Z. Ren, Estimating the base material properties of sintered metallic hollow spheres by inverse engineering procedure. Mech. Mater. 100, 22–30 (2016). https://doi.org/10.1016/j.mechmat.2016.06.001

J. Song, Q. Sun, Z. Yang, S. Luo, X. Xiao, S.R. Arwade, G. Zhang, Effects of microporosity on the elasticity and yielding of thin-walled metallic hollow spheres. Mater. Sci. Eng. A 688, 134–145 (2017). https://doi.org/10.1016/j.msea.2017.01.105

J. Song, Q. Sun, S. Luo, S.R. Arwade, S. Gerasimidis, Y. Guo, G. Zhang, Compression behavior of individual thin-walled metallic hollow spheres with patterned distributions of microporosity. Mater. Sci. Eng. A 734, 453–475 (2018). https://doi.org/10.1016/j.msea.2018.08.016

P. Yu, G. Stephani, S.D. Luo, H. Goehler, M. Qian, Microwave-assisted fabrication of titanium hollow spheres with tailored shell structures for various potential applications. Mater. Lett. 86, 84–87 (2012). https://doi.org/10.1016/j.matlet.2012.07.022

Funding

This study was funded by the National Natural Science Foundation of China (Nos. 51671065 and 11402060), the tackling the key problems of Double Hundred Technology (No. JCKY2018604C004) and the Fundamental Research funds for the Central Universities (No. HEUCFP201730).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, T., Jiang, F., Wang, C. et al. Investigation on Fabrication and Microstructure of Ti–6Al–4V Alloy Hollow Spheres by Powder Metallurgy. Met. Mater. Int. 27, 1083–1091 (2021). https://doi.org/10.1007/s12540-019-00462-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00462-5