Abstract

A physics-based constitutive model of porous materials is proposed to enhance the accuracy of numerical analysis in die/isostatic compaction. The correlation between the yield function and equivalent work equation was derived, and the numerical integration method was modified with the correlation. It is found that the apparent work of porous materials is lower than the product of relative density and equivalent work of solid materials at the beginning of compaction, implying the kinematic motion of powders and the resultant particle rearrangement. For verification of the proposed model, finite element analyses were performed for the die/isostatic compaction of three metal powders: Ti, SUS316L, and Al6061 powders. Compared with two conventional constitutive models, the proposed model improves the accuracy of the densification behaviors in all the stage during die/isostatic compaction. Furthermore, this study is a groundwork to link the densification behavior of porous materials at bulk scale to the particulate behavior of powders at microscale.

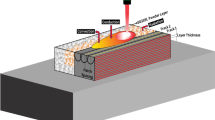

Graphic Abstract

Similar content being viewed by others

References

B.D. Soane, P.S. Blackwell, J.W. Dickson, D.J. Painter, Soil Tillage Res. 1, 373 (1980/1981)

T. Saito, JOM 56, 33 (2004)

J.R. Pickens, J. Mater. Sci. 16, 1437 (1981)

C.L. Martin, D. Bouvard, G. Delette, J. Am. Ceram. Soc. 89, 3379 (2006)

P. Pizette, C.L. Martin, G. Delette, P. Sornay, F. Sans, Powder Technol. 198, 240 (2010)

B. Harthong, J.-F. Jerier, P. Doremus, D. Imbault, F.-V. Donze, Int. J. Solids Struct. 46, 3357 (2009)

B. Harthong, J.-F. Jerier, V. Richefeu, B. Chareyre, P. Doremus, D. Imbault, F.-V. Donze, Int. J. Mech. Sci. 61, 32 (2012)

A. Salvadori, S. Lee, A. Gillman, K. Matous, C. Shuck, A. Mukasyan, M.T. Beason, I.E. Gunduz, S.F. Son, Mech. Mater. 112, 56 (2017)

Y. Huang, J. Li, Y. Teng, X. Dong, X. Wang, G. Kong, T. Song, Powder Technol. 320, 668 (2017)

L. Kempton, D. Pinson, S. Chew, P. Zulli, A. Yu, Powder Technol. 320, 586 (2017)

H.A. Kuhn, C.L. Downey, Int. J. Powder Metall. 7(1), 15 (1971)

S. Shima, M. Oyane, Int. J. Mech. Sci. 18, 285 (1976)

S.M. Doraivelu, H.L. Gegel, J.S. Gunasekera, J.C. Malas, J.T. Morgan, J.F. Thomas, Int. J. Mech. Sci. 26(9/10), 527 (1984)

D.N. Lee, H.S. Kim, Powder Metall. 35, 275 (1992)

H.S. Kim, Meter. Sci. Eng. A 251, 100 (1998)

D.C. Drucker, W. Prager, Q. Appl. Math. 10, 157 (1952)

J. Almanstotter, Int. J. Refract. Met. Hard Mater. 50, 290 (2015)

M. Zhou, S. Huang, J. Hu, Y. Lei, Y. Xiao, B. Li, S. Yan, F. Zou, Powder Technol. 305, 183 (2017)

A.C.F. Cocks, I.C. Sinka, Mech. Mater. 39, 392 (2007)

I.C. Sinka, A.C.F. Cocks, Mech. Mater. 39, 404 (2007)

H. Diarra, V. Mazel, V. Busignies, P. Tchoreloff, Powder Technol. 320, 530 (2017)

N.A. Fleck, J. Mech. Phys. Solids 43, 1409 (1995)

A.R. Akisanya, A.C.F. Cocks, N.A. Fleck, Int. J. Mech. Sci. 39, 1315 (1997)

I. Sridhar, N.A. Fleck, Acta Mater. 48, 3341 (2000)

N. Aravas, Int. J. Numer. Methods Eng. 24, 1395 (1987)

H.S. Kim, Y. Estrin, E.Y. Gutmanas, C.K. Rhee, Mater. Sci. Eng. A 307, 67 (2001)

I.F. Martynova, M.S. Shtern, Soviet Powder Metall. Met. Ceram. 17, 17 (1978)

G.M. Zhdanovich, Theory of Compacting of Metal Powders (Foreign Technology Division Wright-Patterson Air Force Base, Dayton, 1971)

H.A. Kuhn, in Powder Metallurgy Processing: The Techniques and Analyses, ed. by H.A. Kuhn, A. Lawley (Acadamic Press, New York, 1978), p. 99

M.S. Koval’chenko, Powder Metall. Metal Ceram. 32(3), 268 (1993)

Z.L. Zhang, Comput. Methods Appl. Mech. Eng. 121, 29 (1995)

Z.L. Zhang, Comput. Methods Appl. Mech. Eng. 121, 15 (1995)

S.B. Biner, W.A. Spitzig, Acta Metall. Mater. 38(4), 603 (1990)

Y.S. Kwon, H.T. Lee, K.T. Kim, J. Eng. Mater. Technol. 119, 366 (1997)

S.C. Lee, K.T. Kim, Int. J. Mech. Sci. 44, 1295 (2002)

H. Mecking, U.F. Kocks, Acta Matall. 29, 1865 (1981)

Y. Estrin, in Unified Constitutive Laws of Plastic Deformation, ed. by A.S. Krausz, K. Krausz (Academic Press, San Diego, 1996), p. 69

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) Grant funded by the Korea government (MSIP) (No. 2017R1A2A1A17069427).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Seong, Y., Yim, D., Jang, M.J. et al. Physics-Based Constitutive Model of Porous Materials for Die/Isostatic Compaction of Metallic Powders. Met. Mater. Int. 26, 221–229 (2020). https://doi.org/10.1007/s12540-019-00317-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00317-z