Abstract

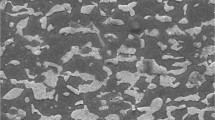

Using alternating current (AC)- and direct current (DC)-type welders, the resistance spot weldability of lightweight steel was evaluated under various electrode forces, welding currents, and times. The acceptable welding conditions were specified; however, these had very narrow ranges and there was little difference between the conditions determined for the AC- and DC-type welding. In both types of welding with electrode forces of of 300 kgf and 400 kgf, the acceptable weld currents were 5.0 kA and 5.5 kA, respectively. Also, the nugget size increased with the welding current. Under the acceptable welding conditions, there were no significant changes in the maximum tensile shear strength and nugget size, as 6.4-6.6 kN and 4.1-4.3 mm, respectively. The microstructure of weld metals was consisted of martensite, austenite and ferrite. And the small fraction of martensite was founded in the heat affected zone (HAZ), therefore the weld metal had the greatest hardness, and HAZ softening did not occur in this study. Considering the fracture surface, cleavage and ductile fracture were investigated because of the existence of martensite and ferrite in the welds.

Similar content being viewed by others

References

P. J. Jacques, Curr. Opin. Solid St. M. 8, 259 (2004).

S. Zaefferer, J. Ohlert, and W. Bleck, Acta Mater. 52, 2765 (2004).

I. B. Timokhina, P. D Hodgson, and E. V. Pereloma, Metall. Mater. Trans. A 35, 2331 (2004).

G. Frommeyer and U. Brüx, Steel Res. Int. 77, 627 (2006).

S. Y. Han, S. Y. Shin, S. Lee, N. J. Kim, J. H. Kwak, and K. Chin, Korean J. Met. Mater. 48, 377 (2010).

B.-W. Choi, D.-H. Seo, and J.-I. Jang, Met. Mater. Int. 15, 373 (2009).

I. Choi, Y. Park, D. Son, S.-J. Kim, and M. Moon, Met. Mater. Int. 16, 27 (2010).

J. Bouquerel, K. Verbeken, and B. C. De Cooman, Acta Mater. 54, 1443 (2006).

S. Vercammen, B. Blanpain, B. C. De Cooman, and P. Wollants, Acta Mater. 52, 2005 (2004).

N. Lim, H. Park, S. Kim, and C. Park, Met. Mater. Int. 18, 647 (2012).

O. Boaziz, S. Allain, C. P. Scott, P. Cugy, and D. Barbier, Curr. Opin. Solid St. M. 15, 141 (2011).

J. E. Jung, J. Park, J.-S. Kim, J. B. Jeon, S. K. Kim, and Y. W. Chang, Met. Mater. Int. 20, 27 (2014).

J.-S. Kim, J. B. Jeon, J. E. Jung, K.-K. Um, and Y. W. Chang, Met. Mater. Int. 20, 27 (2014).

K.-G. Chin, H.-J. Lee, J.-H. Kwak, J.-Y. Kang, and B.-J. Lee, J. Alloy. Compd. 505, 217 (2010).

G. Frommeyer and J. A. Jiménez, Metall. Mater. Trans. A 36, 295 (2005).

B. Hwang, T.-H. Lee, J.-H. Shin, and J.-W. Lee, Korean J. Met. Mater. 52, 21 (2014).

H. Kim, D.-W. Suh, and N. J. Kim, Sci. Technol. Adv. Mater. 14, 1 (2013).

D.-W. Suh, S. J. Park, T. H. Lee, C. S. Oh, and S. J. Kim, Metall. Mater. Trans. A 41, 397 (2010).

H. Huang, D. Gan, and P. W. Kao, Scr. Metall. Mater. 30, 499 (1994).

W. K. Choo, J. H. Kim, and J. C. Yoon, Acta Mater. 45, 4877 (1997).

C. L. Lin, C. G. Chao, H. Y. Bor, and T. F. Liu, Mater. Trans. 51, 1084 (2010).

S. Y. Han, S. Y. Shin, S. Lee, N. J. Kim, J.-H. Kwak, and K.-G. Chin, Metall. Mater. Trans. A 42, 138 (2011).

F. D’Errico, J. Fail. Anal. Preven. 10, 351 (2010).

S. S. Sohn, B.-J. Lee, S. Lee, and J.-H. Kwak, Met. Mater. Int. 21, 43 (2015).

D. J. Radakovic and M. Tumuluru, Weld. J. 87, 96 (2008).

M. I. Khan, M. L. Kuntz, P. Su, A. Gerlich, T. North, and Y. Zhou, Sci. Technol. Weld. Joi. 12, 175 (2007).

M. I. Khan, M. L. Kuntz, and Y. Zhou, Sci. Technol. Weld. Joi. 13, 294 (2008).

G. S. Jung, K. Y. Lee, J. B. Lee, H. K. D. H. Bhadeshia, and D.-W. Suh, Sci. Technol. Weld. Joi. 17, 92 (2012).

S. Daneshpour, S. Riekehr, M. Kocak, V. Ventzke, and A. I. Korkuk, Sci. Technol. Weld. Joi. 12, 508 (2007).

H. L. Yi, K. Y. Lee, J. H. Lim, and H. K. D. H. Bhadeshia, Sci. Technol. Weld. Joi. 15, 619 (2010).

D. C. Saha, S. Han, K. G. Chin, I. Choi, and Y.-D. Park, Steel Res. Int. 83, 352 (2012).

J. Yu, J. Shim, and S. Rhee, Mater. Trans. 53, 2011 (2012).

M. I. Khan, M. L. Kuntz, E. Biro, and Y. Zhou, Mater. Trans. 49, 1629 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hwang, I., Kim, D., Kang, M. et al. Resistance spot weldability of lightweight steel with a high Al content. Met. Mater. Int. 23, 341–349 (2017). https://doi.org/10.1007/s12540-017-6349-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6349-x