Abstract

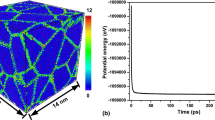

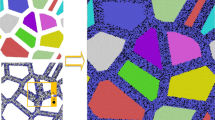

In this paper, molecular dynamics (MD) simulation based study of creep behavior for nanocrystalline (NC) Ni-3 at% Zr alloy having grain size ~ 6 nm has been performed using embedded atom method (EAM) potential to study the influence of variation of temperature (1220-1450 K) as well as change in stress (0.5-1.5 GPa) on creep behavior. All the simulated creep curves for this ultra-fine grained NC Ni-Zr alloy has extensive tertiary creep regime. Primary creep regime is very short and steady state creep part is almost absent. The effect of temperatures and stress is prominent on the nature of the simulated creep curves and corresponding atomic configurations. Additionally, mean square displacement calculation has been performed at 1220 K, 1250 K, 1350 K, and 1450 K temperatures to correlate the activation energy of atomic diffusion and creep. The activation energy of creep process found to be less compared to activation energies of self-diffusion for Ni and Zr in NC Ni-3 at% Zr alloy. Formation of martensite is identified during creep process by common neighbour analysis. Presence of dislocations is observed only in primary regime of creep curve up till 20 ps, as evident from calculated dislocation density through MD simulations. Coble creep is found to be main operative mechanism for creep deformation of ultrafine grained NC Ni-3 at% Zr alloy.

Similar content being viewed by others

References

B. S. Murty, P. Shankar, B. Raj, B. B. Rath, and J. Murday, Textbook of Nanoscience and Nanotechnology, pp.1–28, Springer Berlin Heidelberg, Germany (2013).

R. Kelsall, I. W. Hamley, and M. Geoghegan (Eds.), Nanoscale Science and Technology, pp.272–276, John Wiley & Sons, USA (2005).

H. Gleiter, Prog. Mater. Sci. 33, 223 (1989).

H. Gleiter, Acta Mater. 48, 1 (2000).

C. Suryanarayana, Int. Mater. Rev. 40, 41 (1995).

U. F. Kocks and H. Mecking, Prog. Mater. Sci. 48, 171 (2003).

A. H. Chokshi, A. Rosen, J. Karch, and H. Gleiter, Scripta Metall. Mater. 23, 1679 (1989).

G. W. Nieman, J. R. Weertman, and R. W. Siegel, Scripta Metall. Mater. 23, 2013 (1989).

H. Chang, C. J. Altstetter, and R. S. Averback, J. Mater. Res. 7, 2962 (1992).

V. Yamakov, D. Wolf, M. Salazar, S. R. Phillpot, and H. Gleiter, Acta Mater. 49, 2713 (2001).

J. Schiøtz and K. W. Jacobsen, Science 301, 1357 (2003).

H. V. Swygenhoven, M. Spaczer, and A. Caro, Acta Mater. 47, 3117 (1999).

V. Y. Gertsman, M. Hoffmann, H. Gleiter, and R. Birringer, Acta Metall. Mater. 42, 3539 (1994).

R. A. Masumura, P. M. Hazzledine, and C. S. Pande, Acta Mater. 46, 4527 (1998).

T. G. Desai, P. Millett, and D. Wolf, Mat. Sci. Eng. A 493, 41 (2008).

K. A. Padmanabhan, S. Sripathi, H. Hahn, and H. Gleiter, Mater. Lett. 133, 151 (2014).

M. E. Kassner, Fundamentals of Creep in Metals and Alloys, pp.189–232, Butterworth Heinemann, London, UK (2015).

F. R. N. Nabarro and F. De Villiers, Physics of Creep and Creep-Resistant Alloys, pp.47–65, CRC Press, Bristol, UK (1995).

R. Raj and M. F. Ashby, Metall. Trans. 2, 1113 (1971).

C. Herring, J. Appl. Phys. 21, 437 (1950).

R. L. Coble, J. Appl. Phys. 34, 1679 (1963).

R. Subramanian, A. Metoki, C. V. Alejandro, S. Yamagishi, and M. Okazaki, Mech. Eng. Lett. 1, 15-00461 (2015).

Y. Ashkenazy and R. S. Averback, Nano Lett. 12, 4084 (2012).

F. R. Nabarro, Report of a Conference on the Strength of Solids, p. 75, The Physical Society, London, UK (1948).

S. V. Petegem, S. Brandstetter, B. Schmitt, and H. Van Swygenhoven, Scripta Mater. 60, 297 (2009).

S. Ghosh and A. H. Chokshi, Scripta Mater. 86, 13 (2014).

J. Hu, G. Sun, X. Zhang, G. Wang, Z. Jiang, S. Han, et al. J. Alloy. Compd. 647, 670 (2015).

J. Berry, J. Rottler, C. W. Sinclair, and N. Provatas, Phys. Rev. B 92, 134103 (2015).

Y. J. Wang, A. Ishii, and S. Ogata, Mater. Trans. 53, 156 (2012).

P. Keblinski, D. Wolf, and H. Gleiter, Interface Sci. 6, 205 (1998).

V. Yamakov, D. Wolf, S. R. Phillpot, and H. Gleiter, Acta Mater. 50, 61 (2002).

P. C. Millett, T. Desai, V. Yamakov, and D. Wolf, Acta Mater. 56, 3688 (2008).

Y. J. Wang, A. Ishii, and S. Ogata, Phys. Rev. B 84, 224102 (2011).

M. Meraj and S. Pal, T. Indian I. Metals 69, 277 (2015).

M. A. Bhatia, S. N. Mathaudhu, and K. N. Solanki, Acta Mater. 99, 382 (2015).

B. N. Kim, K. Hiraga, Y. Sakka, and B. W. Ahn, Acta Mater. 47, 3433 (1999).

B. N. Kim and K. Hiraga, Acta Mater. 48, 4151 (2000).

A. J. Haslam, D. Moldovan, V. Yamakov, D. Wolf, S. R. Phillpot, and H. Gleiter, Acta Mater. 51, 2097 (2003).

J. W. Cahn and J. E. Taylor, Acta Mater. 52, 4887 (2004).

Z. T. Trautt, A. Adland, A. Karma, and Y. Mishin, Acta Mater. 60, 6528 (2012).

C. H. Konrad, R. Völkl, and U. Glatzel, Oxid. Met. 77, 149 (2012).

D. Chen, Comp. Mater. Sci. 3, 327 (1995).

J. Li, Model. Simul. Mater. Sc. 11, 173 (2003).

S. L. Gafner, L. V. Redel, and Y. Y. Gafner, J. Exp. Theor. Phys. 114, 428 (2012).

W. Ding, H. He, and B. Pan, J. Mater. Sci. 50, 5684 (2015).

J. D. Honeycutt and H. C. Andersen, J. Phys. Chem. 91, 4950 (1987).

D. Faken and H. Jónsson, Comp. Mater. Sci. 2, 279 (1994).

C. L. Kelchner, S. J. Plimpton, and J. C. Hamilton, Phys. Rev. B 58, 11085 (1998).

S. Plimpton, J. Comput. Phys. 117, 1 (1995).

S. R. Wilson and M. I. Mendelev, Philos. Mag. 95, 224 (2015).

A. Stukowski, Model. Simul. Mater. Sc. 18, 015012 (2010).

S. Gollapudi, K. V. Rajulapati, I. Charit, C. C. Koch, R. O. Scattergood, and K. L. Murty, Mat. Sci. Eng. A 527, 5773 (2010).

C. Ni, H. Ding, and X. J. Jin, J. Alloy. Compd. 546, 1 (2013).

T. Song and B. C. De Cooman, ISIJ Int. 54, 2394 (2014).

S. Kajiwara, Metall. Mater. Trans. A 17, 1693 (1986).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meraj, M., Pal, S. Effect of temperature and stress on creep behavior of ultrafine grained nanocrystalline Ni-3 at% Zr alloy. Met. Mater. Int. 23, 272–282 (2017). https://doi.org/10.1007/s12540-017-6144-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6144-8