Abstract

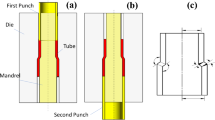

In this paper, ultrafine-grained (UFG) Cu-Zn tubes were processed via multi-pass parallel tubular channel angular pressing (PTCAP) process, and microstructure, mechanical properties along the axial and peripheral directions were evaluated. Mechanical characterizations were done using uniaxial tension test along both the axial and peripheral directions and biaxial bulging tests. The hydro-bulging test was used to measure the bursting pressure of UFG tubes. The results present that the UFG and nanostructured tubes achieved form PTCAP process exhibit excellent pressure bearing capacity in comparison with the coarse-grained (CG) counterparts. Also, the bursting pressure of the UFG tube was remarkably increased to 93 MPa just after the first pass of PTCAP process from 43.3 MPa for the CG one. It was 88 MPa and 81.3 MPa for second and third passes PTCAP processed tube. Important reasons for this behavior were both significant grain refinement and severe mechanical anisotropy results from texture evolution after PTCAP processing.

Similar content being viewed by others

References

M. Ahmetoglu and T. Altan, J. Mater. Process. Tech. 98, 25 (2000).

M. Koç and T. Altan, J. Mater. Process. Tech. 108, 384 (2001).

L. H. Lang, Z. R. Wang, D. C. Kang, S. J. Yuan, S. H. Zhang, J. Danckert, and K. B. Nielsen, J. Mater. Process. Tech. 151, 165 (2004).

B. J. Mac Donald and M. S. J. Hashmi, J. Mater. Process. Tech. 120, 341 (2002).

Y. Aue-U-Lan, G. Ngaile, and T. Altan, J. Mater. Process. Tech. 146, 137 (2004).

G. T. Kridli, L. Bao, P. K. Mallick, and Y. Tian, J. Mater. Process. Tech. 133, 287 (2003).

M. Atkinson, Int. J. Mech. Sci. 39, 761 (1997).

R. Z. Valiev, R. K. Islamgaliev, and I. V. Alexandrov, Prog. Mater. Sci. 45, 103 (2000).

G. Faraji, M. M. Mashhadi, and H. S. Kim, Mater. Lett. 65, 3009 (2011).

A. Babaei, M.M. Mashhadi, and H. Jafarzadeh, Mat. Sci. Eng A-Struct, 598, 1 (2014).

L. S. Tóth, M. Arzaghi, J. J. Fundenberger, B. Beausir, O. Bouaziz, and R. Arruffat-Massion, Scripta Mater. 60, 175 (2009).

G. Faraji, A. Babaei, M. M. Mashhadi, and K. Abrinia, Mater. Lett. 77, 82 (2012).

N. Svensson, J. Appl. Mech. 25, 89 (1958).

J. Hu, Z. Marciniak, and J. Duncan, Mechanics of Sheet Metal Forming, p.17, Butterworth-Heinemann, Oxford (2002).

J. Hu, Z. Marciniak, and J. Duncan, Mechanics of Sheet Metal Forming, Butterworth-Heinemann (2002).

Y.-L. Lin, Z.-B. He, S.-J. Yuan, and J. Wu, T. Nonferr. Metal. Soc. 21, 851 (2011).

G. Faraji, M. M. Mashhadi, and H. S. Kim, Mat. Sci. Eng A-Struct, 528, 4312 (2011).

G. Faraji, M. M. Mashhadi, A. R. Bushroa, and A. Babaei, Mat. Sci. Eng A-Struct, 563, 193 (2013).

A. V. Nagasekhar, T. Rajkumar, D. Stephan, Y. Tick-Hon, R. K. Guduru, Mat. Sci. Eng A-Struct, 524, 204 (2009).

S. Pasebani and M. R. Toroghinejad, Mat. Sci. Eng A-Struct, 527, 491 (2010).

D. H. Shin, C. W. Seo, J. Kim, K.-T. Park, and W. Y. Choo, Scripta Mater. 42, 695 (2000).

V. Tavakkoli, M. Afrasiab, G. Faraji, and M. M. Mashhadi, Mat. Sci. Eng A-Struct, 625, 50 (2015).

W. J. Kim, C. W. An, Y. S. Kim, and S. I. Hong, Scripta Mater. 47, 39 (2002).

L. Jiang, J.J. Jonas, K. Boyle, and P. Martin, Mat. Sci. Eng A-Struct, 492, 68 (2008).

C. Gu, J. Lian, Z. Jiang, and Q. Jiang, Scripta Mater. 54, 579 (2006).

F. Salimyanfard, M. R. Toroghinejad, F. Ashrafizadeh, and M. Jafari, Mat. Sci. Eng A-Struct, 528, 5348 (2011).

M. Imaninejad, G. Subhash, and A. Loukus, J. Mater. Process. Tech. 147, 247 (2004).

M. Koç and T. Altan, International Journal of Machine Tools and Manufacture, 42, 123 (2002).

T. Minoda, K. Shibue, and H. Yoshida, Journal-Japan Institute of Light Metals, 54, 110 (2004).

E. J. Pavlina, C. J. Van Tyne, and K. Hertel, J. Mater. Process. Tech. 201, 242 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdolvand, H., Faraji, G., Givi, M.K.B. et al. Evaluation of the microstructure and mechanical properties of the ultrafine grained thin-walled tubes processed by severe plastic deformation. Met. Mater. Int. 21, 1068–1073 (2015). https://doi.org/10.1007/s12540-015-5261-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-5261-5