Abstract

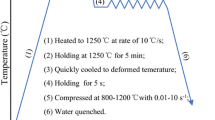

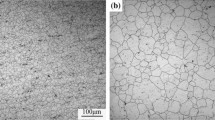

The hot deformation behavior of an ultra-pure 17%Cr ferritic stainless steel was studied in the temperature range of 750–1000 °C and strain rates of 0.5 to 10 s−1 using isothermal hot compression tests in a thermomechanical simulator. The microstructural evolution was investigated using electron backscattered diffraction and transmission electron microscopy. A modified constitutive equation considering the effect of strain on material constant was developed, which predicted the flow stress for the deformation conditions studied, except at 950 °C in 1 s−1 and 900 °C in 10 s−1. Decreasing deformation temperature and increasing strain was beneficial in refining the microstructure. Decreasing deformation temperature, the in-grain shear bands appeared in the microstructure. It is suggested that the dynamic softening mechanism is closely related to deformation temperature. At low deformation temperature, dynamic recovery was major softening mechanism and no dynamic recrystallization occurred. At high deformation temperature, dynamic softening was explained in terms of efficient dynamic recovery and limited continuous dynamic recrystallization. A drop in the flow stress was not found due to very small fraction of new grains nucleated during dynamic recrystallization.

Similar content being viewed by others

References

K. H. Lo, C. H. Shek, and J. K. L. Lai, Mater. Sci. Eng. R 65, 39 (2009).

S. M. Kim, Y. S. Chun, S. Y. Won, Y. H. Kim, and C. S. Lee, Metall. Mater. Trans. A 44A, 1331 (2013).

C. Zhang, Z. Y. Liu, and G. D. Wang, J. Mater. Process. Technol. 211, 1051 (2011).

C. Zhang, Z. Y. Liu, Y. Xu, and G. D. Wang, J. Mater. Process. Technol. 212, 2183 (2012).

F. Gao, Z. Y. Liu, H. T. Liu, and G. D. Wang, Mater. Charact. 75, 93 (2013).

J. J. Jonas, J. Mater. Process. Technol. 117, 293 (2001).

M. R. Toroghinejad, A. O. Humphreys, D. S. Liu, F. Ashrafizadeh, A. Najafizadeh, and J. J. Jonas, Metall. Mater. Trans. A 34A, 1163 (2003).

R. N. Wright, Toughness of Ferritic Stainless Steels, pp.2–33, American Society for Testing and Materials, Philadelphia (1980).

J. Zhou, J. B. Zhang, G. S. Ji, and D. Fan, Trans. Mater. Heat Treat. (China) 31, 50 (2010).

L. H. Yang, L. J. Li, Y. Z. Liu, and L. Y. Zhou, Heat Treat. Met. 36, 78 (2011).

F. Gao, Z. Y. Liu, and G. D. Wang, J. Northeast Univ., Nat. Sci. (China) 32, 1406 (2011).

C. Zhang, Z. Y. Liu, and G. D. Wang, J. Iron Steel Res. (China) 22(12), 27 (2010).

S. V. Mehtonen, L. P. Karjalainen, and D. A. Porter, Mater. Sci. Eng. A 571, 1 (2013).

H. T. Liu, M. Wang, F. Gao, and Z. Y. Liu, J. Northeast Univ., Nat. Sci. (China) 33, 1734 (2012).

S.-I. Kim and Y.-C. Yoo, Met. Mater. Int. 8, 7 (2002).

F. Gao, Y. R. Xu, B. Y. Song, and K. Xia, Metall. Mater. Trans. A 31A, 21 (2000).

F. A. Slooff, J. Zhou, J. Duszczyk, and L. Katgerman, Scripta Mater. 57, 759 (2007).

F. A. Slooff, J. Zhou, J. Duszczyk, and L. Katgerman, J. Mater. Sci. 43, 7165 (2008).

S. Mandal, V. Rakesh, P. V. Sivaprasad, S. Venugopal, and K. V. Kasiviswanathan, Mater. Sci. Eng. A 500, 114 (2009).

H. Mirzadeh, J. M. Cabrera, and A. Najafizadeh, Metall. Mater. Trans. A 43A, 108 (2012).

Y. C. Lin, M.-S. Chen, and J. Zhong, Comput. Mater. Sci. 42, 470 (2008).

Y. C. Lin, M.-S. Chen, and J. Zhong, Mater. Sci. Eng. A 499, 88 (2009).

X. P. Liang, Y. Liu, H.-Z. Li, C.-X. Zhou, and G.-F. Xu, Mater. Des. 37, 40 (2012).

A. Etaati, K. Dehghani, G. R. Ebrahimi, and H. Wang, Met. Mater. Int. 19, 5 (2013).

S. Gourdet and F. Montheillet, Acta Mater. 51, 2685 (2003).

D. G. Cram, H. S. Zurob, Y. J. M. Brechet, and C. R. Hutchinson, Acta Materialia. 57, 5218 (2009).

W. Blum, Q. Zhu, R, Merkel, and H. J. McQueen, Mater. Sci. Eng. A 205, 23 (1996).

M. R. Branett and J. J. Jonas, ISIJ Int. 37, 697 (1997).

C. M. Sellars and W. J. McTegart, Acta Metall. 14, 1136 (1966).

C. Zener and J. H. Hollomon, J. Appl. Phys. 15, 22 (1944).

C. Zhang, Ph. D. Thesis, pp.109–112, Northeastern University, Shenyang, China (2011).

M. E. Kassner, M. Z. Wang, M.-T. Perez-prado, and S. Alhajeri, Metall. Mater. Trans. A 33A, 3145 (2002).

G. J. Baczynski, J. J. Jonas, and L. E. Collins, Metall. Mater. Trans. A 30A, 3045 (1999).

D. Samantaray, C. Phaniraj, S. Mandal, and A. K. Bhaduri, Mater. Sci. Eng. A 528, 1071 (2011).

S. Gourdet and F. Montheillet, Mater. Sci. Eng. A 283, 274 (2000).

J. K. Solberg, H. J. McQueen, N. Ryum, and E. Nes, Philos. Mag. A 60, 447 (1989).

M. E. Kassner and S. R. Barrabes, Mater. Sci. Eng. A 410–411, 152 (2005).

F. Gao, Z. Y. Liu, H. T. Liu, and G. D. Wang, J. Iron Steel Res. Int. 20, 31 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, F., Liu, Z., Misra, R.D.K. et al. Constitutive modeling and dynamic softening mechanism during hot deformation of an ultra-pure 17%Cr ferritic stainless steel stabilized with Nb. Met. Mater. Int. 20, 939–951 (2014). https://doi.org/10.1007/s12540-014-5020-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-014-5020-z