Abstract

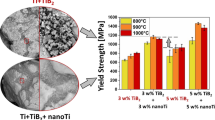

This study investigated the microstructure and tensile behavior of (TiB+TiC) reinforced titanium matrix composites (TMCs) using an in-situ reaction between Ti and B4C. Different B4C sizes (1,500 and 150 μm) and contents (0.94, 1.88 and 3.76 mass%) were added to pure Ti to produce 5, 10, and 20 vol% (TiB+TiC) reinforced TMCs. In-situ synthesized TiB and TiC reinforcements prepared with 150 μm B4C were very fine, and were distributed more homogeneously than the 1,500 μm B4C. As the TiB and TiC contents increased, the tensile strength increased and the ductility decreased compared to unreinforced pure Ti. The improvements in the tensile strength of TMCs were obtained by load transfer strengthening and an alpha-Ti matrix grain reduction of 9–26%. In addition, the TMCs produced using 150 μm B4C showed a greater tensile elongation of approximately 61–117%, with a slightly improved strength compared to that with 1,500 μm B4C. The tensile elongation of TMCs obtained with 150 μm B4C was enhanced because the coarse reinforcements produced by 1,500 μm B4C were more easily and frequently cracked at the fracture surface.

Similar content being viewed by others

References

T. W. Clyne, P. J. Withers, An Introduction to Metal Matrix Composites, p.1, Cambridge University Press, UK (1993).

D. B. Miracle, S. L. Donaldson, ASM Handbook Vol. 21 Composites, p.579, ASM International, US (2001).

C. Leyens, M. Peters, Titanium and Titanium Alloys, p. 305, WILEY-VCH, Germany (2003).

G. Luo, Q. Zhen, J. Deng, Titanium ′95: Science and Technology, p. 2704, The Institute of Materials, UK (1995).

S. Abkowitz, S. M. Abkowitz, H. Fisher and P. J. Schwartz, JOM 56, 37 (2004).

D. R. Ni, Script. Mater. 55, 429 (2006).

H. T. Tsang, Script. Metall. Mater. 37, 1359 (1997).

M. G. Cortazar, I. Agote, E. Silveira, P. Egizabal, J. Coleto, and Y. L. Petitcorps, JOM 60, 40 (2008).

A. K. Sachdev, K. Kulkarni, Z. Z. Fang, R. Yang, and V. Girshov, JOM 64, 553 (2012).

B. J. Choi and Y. J. Kim, Met. Mater. Int. 19, 439 (2013).

S. Ranganath, J. Mater. Sci. 32, 1 (1997).

S. Y. Sung and Y. J. Kim, Mater. Trans. 46, 726 (2005).

S. C. Tjong and Z. Y. Ma, Mater. Sci. Eng. 29, 49 (2000).

B. J. Choi, S. Lee, and Y. J. Kim, Korean J. Met. Mater. 49, 577 (2011).

Y. B. Chun and S. K. Hwang, Acta Mater. 56, 369 (2008).

B. J. Choi and Y. J. Kim, Mater. Trans. 52, 1926 (2011).

B. J. Choi and Y. J. Kim, Korean. J. Met. Mater. 48, 780 (2010).

H. D. Duschanek, P. Rogl, and H. L. Lukas, J. Phase Equil. 16, 46 (1995).

X. Zhang, W. Lu, D. Zhang, and R. Wu, Scripta Mater. 41, 39 (1999).

I. A. Ibrahim, F. A. Mohamed, and E. J. Lavernia, J. Mater. Sci. 26, 1137 (1991).

F. Tang, I. E. Anderson, T. G. Herold, and H. Prask, Mater. Sci. Eng. A 383, 362 (2004).

R. J. Arsenault and N. Shi, Mater. Sci. Eng. 81, 175 (1986).

Z. Zhang and D. L. Chen, Script. Mater. 54, 1321 (2006).

M. Taya and R. J. Arsenault, Script. Metall. 21, 349 (1987).

V. C. Nardone and K. M. Prewo, Script. Metall. 20, 43 (1986).

W. Lu, D. Zhang, X. Zhang, Y. Bian, R. Wu, T. Sakata, and H. Mori, J. Mater. Sci. 36, 3707 (2001).

T. W. Clyne, P. J. Withers, An Introduction to Metal Matrix Composites, p.85, Cambridge University Press, UK (1993).

M. J. Donachie, Jr, Titanium — A Technical Guide, 2nd eds, p.144, ASM International, US (2000).

N. Chawla and K. K. Chawla, Metal Matrix Composites, p.223, Springer, US (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, BJ., Kim, YJ. In-Situ (TiB+TiC) particulate reinforced titanium matrix composites: Effect of B4C size and content. Met. Mater. Int. 19, 1301–1307 (2013). https://doi.org/10.1007/s12540-013-6024-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-6024-9