Abstract

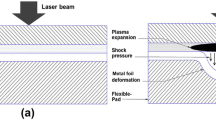

Flexible Pad Laser Shock Forming (FPLSF) is a new microforming process using laser-induced shock pressure and a hyperelastic flexible pad to induce high strain-rate (~105 s−1) plastic deformation on metallic foils to produce 3D microcraters. This paper studies the effect of two significant process parameters of FPLSF, flexible pad material and its thickness, on the deformation characteristics of the metal foils using experiments and finite element analysis. A finite element model is developed to simulate the FPLSF process. The stress-strain distribution across the foil and the flexible pad at different process stages of FPLSF are studied using FE analysis. Flexible pad materials including silicone rubber, polyurethane rubber, and natural rubber with thicknesses ranging between 300 μm and 3000 μm have been investigated in detail. Experimental results highlight that both the hardness and thickness of the flexible pad significantly influence the deformed crater geometry, thickness distribution across the formed crater and surface hardness at the crater surfaces. The experimental results are correlated with the stress-strain distributions from finite element analysis to study the underlying behaviors.

Similar content being viewed by others

References

Nagarajan B, Castagne S, Wang Z (2013) Mold-free fabrication of 3D microfeatures using laser-induced shock pressure. Appl Surf Sci 268 (0):529–534. doi:10.1016/j.apsusc.2012.12.163

Nagarajan B, Castagne S, Wang Z (2013) Influence of Process Parameters on the Deformation of Copper Foils in Flexible-Pad Laser Shock Forming. Paper presented at the 8th International Conference on MicroManufacturing, University of Victoria, Victoria BC, Canada

Ramezani M, Ripin ZM, Ahmad R (2010) Sheet metal forming with the aid of flexible punch, numerical approach and experimental validation. CIRP J Manuf Sci Technol 3(3):196–203. doi:10.1016/j.cirpj.2010.11.002

Liu Y, Hua L, Lan J, Wei X (2010) Studies of the deformation styles of the rubber-pad forming process used for manufacturing metallic bipolar plates. J Power Sources 195(24):8177–8184. doi:10.1016/j.jpowsour.2010.06.078

Thiruvarudchelvan S (1993) Elastomers in metal forming: a review. J Mater Process Technol 39(1–2):55–82. doi:10.1016/0924-0136(93)90008-t

Liu Y, Hua L (2010) Fabrication of metallic bipolar plate for proton exchange membrane fuel cells by rubber pad forming. J Power Sources 195(11):3529–3535. doi:10.1016/j.jpowsour.2009.12.046

Peng L, Hu P, Lai X, Mei D, Ni J (2009) Investigation of micro/meso sheet soft punch stamping process – simulation and experiments. Mater Des 30(3):783–790. doi:10.1016/j.matdes.2008.05.074

Peng L, Ni J, Liu Da HP, Lai X (2010) Fabrication of metallic bipolar plates for proton exchange membrane fuel cell by flexible forming process-numerical simulations and experiments. J Fuel Cell Sci Tech 7(3):031009–031009. doi:10.1115/1.3207870

Dirikolu MH, Akdemir E (2004) Computer aided modelling of flexible forming process. J Mater Process Technol 148(3):376–381. doi:10.1016/j.jmatprotec.2004.02.049

Wang X, Du D, Zhang H, Shen Z, Liu H, Zhou J, Liu H, Hu Y, Gu C (2013) Investigation of microscale laser dynamic flexible forming process - simulation and experiments. Int J Mach Tools Manuf 67(0):8–17. doi:10.1016/j.ijmachtools.2012.12.003

Lim SS, Kim YT, Kang CG (2013) Fabrication of aluminum 1050 micro-channel proton exchange membrane fuel cell bipolar plate using rubber-pad-forming process. Int J Adv Manuf Technol 65(1–4):231–238. doi:10.1007/s00170-012-4162-8

Watari H, Ona H, Yoshida Y (2003) Flexible punching method using an elastic tool instead of a metal punch. J Mater Process Technol 137(1–3):151–155. doi:10.1016/s0924-0136(02)01080-4

Son C-Y, Jeon Y-P, Kim Y-T, Kang C-G (2012) Evaluation of the formability of a bipolar plate manufactured from aluminum alloy Al 1050 using the rubber pad forming process. Proc Inst Mech Eng Part B-J Eng Manuf. doi:10.1177/0954405411434446

Sala G (2001) A numerical and experimental approach to optimise sheet stamping technologies: part II – aluminium alloys rubber-forming. Mater Des 22(4):299–315. doi:10.1016/s0261-3069(00)00088-1

Ramezani M, Ripin ZM (2012) Analysis of deep drawing of sheet metal using the marform process. Int J Adv Manuf Technol 59(5):491–505. doi:10.1007/s00170-011-3513-1

Fabbro R, Fournier J, Ballard P, Devaux D, Virmont J (1990) Physical study of laser-produced plasma in confined geometry. J Appl Phys 68(2):775–784. doi:10.1063/1.346783

Zhang W, Yao YL (2002) Micro scale laser shock processing of metallic components. J Manuf Sci Eng -Trans ASME 124(2):369–378. doi:10.1115/1.1445149

Liu H, Shen Z, Wang X, Wang H (2009) Numerical simulation and experimentation of a novel laser indirect shock forming. J Appl Phys 106(6):063107. doi:10.1063/1.3212992

Devaux D, Fabbro R, Tollier L, Bartnicki E (1993) Generation of shock waves by laser-induced plasma in confined geometry. J Appl Phys 74(4):2268–2273. doi:10.1063/1.354710

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates, and high temperatures. Proceedings of Seventh International Symposium on Ballistics, The Hague, The Netherlands, pp. 541–547

Bae G, Xiong Y, Kumar S, Kang K, Lee C (2008) General aspects of interface bonding in kinetic sprayed coatings. Acta Mater 56(17):4858–4868. doi:10.1016/j.actamat.2008.06.003

Tounsi N, Vincenti J, Otho A, Elbestawi MA (2002) From the basic mechanics of orthogonal metal cutting toward the identification of the constitutive equation. Int J Mach Tools Manuf 42(12):1373–1383. doi:10.1016/S0890-6955(02)00046-9

Martins PALS, Natal Jorge RM, Ferreira AJM (2006) A comparative study of several material models for prediction of hyperelastic properties: application to silicone-rubber and soft tissues. Strain 42(3):135–147. doi:10.1111/j.1475-1305.2006.00257.x

Fabbro R, Peyre P, Berthe L, Scherpereel X (1998) Physics and applications of laser-shock processing. J Laser Appl 10(6):265–279. doi:10.2351/1.521861

Nagarajan B, Wang Z, Castagne S, Zheng H (2014) Investigation of laser-induced plasma evolution in flexible pad laser shock forming with high speed camera. Appl Surf Sci 308:221–229. doi:10.1016/j.apsusc.2014.04.139

Acknowledgments

This work was supported by the Machining Technology Group, Singapore Institute of Manufacturing Technology under CRP Project Number U11-M-013 U and Nanyang Technological University research scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nagarajan, B., Castagne, S., Wang, Z. et al. Influence of plastic deformation in flexible pad laser shock forming – experimental and numerical analysis. Int J Mater Form 10, 109–123 (2017). https://doi.org/10.1007/s12289-015-1264-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-015-1264-5