Abstract

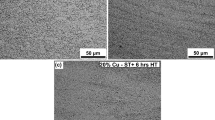

Excessive tool wear generated during the plunge phase of Friction Stir Welding is hindering the application of Friction Stir Welding to hard materials such as steel. In this research we introduce a donor material concept by which we develop localized pre-heating that minimizes the forces throughout the tool which results in reducing tool fracturing and subsequent production replacement. Initial donor material experiments of Cu/Al were conducted to confirm the feasibility of applying this method to the FSW process. Scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDX) images of the donor material depict no mixing of Cu with Al at the interface of the Al plate during plunge. The microstructural images indicate formation of columnar grains and grains recrystallization at the interface. The EDX images that represent several locations from shallow at the surface of the Cu plate to deep positions inside the plunge zone of the Al plate indicate the progression of the Cu/Al composite. A finite element model of the Johnson-Cook material constitutive law is used to investigate the shear stresses, axial forces, and temperature developed during the plunge stage in donor material and steel.

Similar content being viewed by others

References

Thomas WM, Nicholas, E.D., Needham, J.C., Murch. M.G., Temple-Smith, P. and Dawes, C.J (1991) Friction Stir Butt Welding. GB Patent,

Penalva ML, Otaegi A, Pujana J, Rivero (2009) A Development of a new joint geometry for FSW. In: Third Manufacturing Engineering Society International Conference, MESIC-09, 17-19 June 2009, USA. AIP Conf. Proc. (USA). American Institute of Physics, pp 1–11. doi:10.1063/1.3273630

Miller KS, Tolle CR, Clark DE, Nichol CI, McJunkin TR, Smartt HB (2009) Investigation into interface lifting within FSW lap welds. In: 8th International Conference on Trends in Welding Research, June 1, 2008 - June 6, 2008, Pine Mountain, GA, United states. ASM Proceedings of the International Conference: Trends in Welding Research. ASM International, pp 133–139. doi:10.1361/cp2008twrl33

Buffa G, Fratini L, Micari F (2009) A neural network based approach for the design of FSW processes. Key Engineering Materials 410–411:413–420. doi:10.4028/www.scientific.net/KEM.410-411.413

Butan D, Monaghan J (2009) Thermomechanical modelling friction stir welding aluminium 2024-T3. Int J Comput Mater Sci Surf Eng 2(1–2):63–72. doi:10.1504/ijcmsse.2009.024924

Liu H, Zhou L, Huang Y, Liu Q (2010) Study of the key issues of friction stir welding of titanium alloy. In: 6th International Conference on Processing and Manufacturing of Advanced Materials - THERMEC’2009, August 25, 2009 - August 29, 2009, Berlin, Germany. Materials Science Forum. Trans Tech Publications Ltd, pp 1185–1190. doi:10.4028/www.scientific.net/MSF.638-642.1185

Lertora E, Gambaro C (2010) AA8090 Al-Li Alloy FSW parameters to minimize defects and increase fatigue life. Int J Mater Form 3(suppl 1):1003–1006. doi:10.1007/s12289-010-0939-1

Huijie L, Li Z, Yongxian H, Qiwei L (2009) Study of the Key Issues of Friction Stir Welding of Titanium Alloy. Materials Science Forum 638–642:1185–1190. doi:10.4028/www.scientific.net/MSF.638-642.1185

Rajakumar S, Muralidharan C, Balasubramanian V (2010) Optimization of the friction-stir-welding process and tool parameters to attain a maximum tensile strength of AA7075-T6 aluminium alloy. Proceedings of the Institution of Mechanical Engineers, Part B (Journal of Engineering Manufacture) 224(B8):1175–1191. doi:10.1243/09544054jem1802

Hattingh DG, Blignault C, van Niekerk TI, James MN (2008) Characterization of the influences of FSW tool geometry on welding forces and weld tensile strength using an instrumented tool. J Mater Process Technol 203(1–3):46–57. doi:10.1016/j.jmatprotec.2007.10.028

Schneider JA, Nunes AC Jr, Chen PS, Steele G (2005) TEM study of the FSW nugget in AA2195-T81. J Mater Sci 40(16):4341–4345. doi:10.1007/s10853-005-2808-8

Ghidini T, Donne CD, Mercado UA (2011) Predicting the fatigue life of pristine and pre-corroded friction stir welded joints. International Journal of Structural Integrity 2(2):200–213. doi:10.1108/17579861111135932

Weon-Kyong K, Si-Tae W, Byeong-Choon G (2010) A study on mechanical characteristics of the friction stir welded A6005-T5 extrusion. Int J Precis Eng Manuf 11(6):931–936. doi:10.1007/s12541-010-0113-1

McKeown C, Webb P (2011) A reactive reconfigurable tool for aerospace structures. Assem Autom 31(4):334–343. doi:10.1108/01445151111172916

Longhurst WR, Strauss AM, Cook GE (2011) The Identification of the Key Enablers for Force Control of Robotic Friction Stir Welding. J Manuf Sci Eng 133(3):031008 (1–11). doi:10.1115/1.4004132

Park SHC, Sato YS, Kokawa H, Okamoto K, Hirano S, Inagaki M (2009) Boride formation induced by pcBN tool wear in friction-stir-welded stainless steels. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science 40 (Compendex):625-636

Sterling CJ, Nelson TW, Sorensen CD, Steel RJ, Packer SM Friction stir welding of quenched and tempered C-Mn steel. In: Friction Stir Welding and Processing II, March 2, 2003 - March 6, 2003, San Diego. CA, United states, 2003. TMS Annual Meeting. Minerals, Metals and Materials Society, pp 165–171

Sorensen C, Nielsen B Exploring Geometry Effects for Convex Scrolled Shoulder, Step Spiral Probe FSW Tools. In: TMS 2009 Annual Meeting and Exhibition, February 16, 2009 - February 19, 2009, San Francisco, CA, United states, 2009. TMS Annual Meeting. Minerals, Metals and Materials Society, pp 85–92

Mandal S, Williamson K (2006) A thermomechanical hot channel approach for friction stir welding. Journal of Materials Processing Technology 174 (Compendex):190–194

Lienert TJ, Stellwag Jr WL, Grimmett BB, Warke RW (2003) Friction stir welding studies on mild steel. Welding Journal (Miami, Fla) 82 (Compendex):1–9

Thomas WM (1999) Feasibility of Friction Stir Welding Steel. Sci Technol Weld Join 4:365–372

Daftardar S (2009) Laser Assisted Friction Stir Welding: Finite Volume Method and Metals Euristic Optimiation. Louisiana State University, Louisiana

Mandal S, Rice J, Elmustafa AA (2008) Experimental and numerical investigation of the plunge stage in friction stir welding. Journal of Materials Processing Technology 203 (Copyright 2008, The Institution of Engineering and Technology):411–419

Acknowledgement

The authors acknowledge Gene Roarty of Newport News Shipbuilding for preparing the samples and Brandt Robertson of William and Mary Microscopy Lab for the SEM and HIROX images.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rice, J.M., Mandal, S. & Elmustafa, A.A. Microstructural investigation of donor material experiments in friction stir welding. Int J Mater Form 7, 127–137 (2014). https://doi.org/10.1007/s12289-012-1110-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1110-y