Abstract

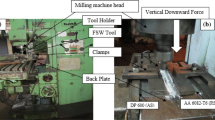

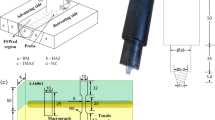

In this study, the microstructure and mechanical properties of dissimilar friction stir welded aluminum and steel joints were investigated, in order to understand the role of tool offset in the enhancement of weld properties. Conventional techniques like light-optical microscopy, electron back scatter diffraction, energy dispersive spectroscopy, and indentation tests were utilized to characterize the joints. Tool offset resulted in a mode of welding where minimal shear strain accumulation in steel and complete dynamic recrystallization of aluminum were achieved. Additionally, macroscopically defect and inter-metallic compound free joints were obtained, with only a small fraction of Fe chips embedded in the aluminum matrix. Through plastic deformation and thermal effects, significant differences in grain size and micro-hardness were observed in the various regions of the welded joint. Due to high temperatures and strain rates, dynamic recrystallization was activated in aluminum. The kernel average misorientation map revealed the lack of stored deformation energy in the microstructure, indicating the presence of fully recrystallized grains. Due to its high thermal stability, steel did not recrystallize but, exhibited marginal grain growth in both thermo-mechanically affected zone and heat-affected zone. It also contained a highly refined grain structure in the weld zone. The texture maps plotted for the weld zone of Fe alloy showed weak shear texture indicating minimal shear strain accumulation. A good correlation between the experimental and predicted hardness was observed in steel. In the aluminum alloy, however, prediction was overestimation as the additional softening due to dynamic recrystallization and dissolution or coarsening of precipitates was not taken into account by the model.

Similar content being viewed by others

References

Mallick P (2010) 8 - joining for lightweight vehicles. In: Mallick P (ed) Materials, design and manufacturing for lightweight vehicles, woodhead publishing series in composites science and engineering. Woodhead Publishing, pp 275–308. https://doi.org/10.1533/9781845697822.2.275. http://www.sciencedirect.com/science/article/pii/B9781845694630500080

Benedyk J (2010) 3 - aluminum alloys for lightweight automotive structures. In: Mallick P (ed) Materials, design and manufacturing for lightweight vehicles, woodhead publishing series in com- posites science and engineering. Woodhead Publishing, pp 79–113. https://doi.org/10.1533/9781845697822.1.79. http://www.sciencedirect.com/science/article/pii/B9781845694630500031

Schwabe J (2014) Entwicklung von dichtereduzierten Feinblechstählen für Automobilanwendungen. Ph.D. thesis, RWTH Aachen University. http://publications.rwth-aachen.de/record/444902

Springer H, Kostka A, dos Santos J, Raabe D (2011) Influence of intermetallic phases and Kirkendall - porosity on the mechanical properties of joints between steel and Aluminium alloys. Mater Sci Eng A 528(13–14):4630–4642. https://doi.org/10.1016/j.msea.2011.02.057. https://doi.org/10.1016/j.msea.2011.02.057. http://www.sciencedirect.com/science/article/pii/S0921509311002218

Abbasi M, Dehghani M, Guim H-U, Kim D-I (2016) Investigation of Fe-rich fragments in aluminum-steel friction stir welds via simultaneous Transmission Kikuchi Diffraction and ED. Acta Mater 117:262–269. https://doi.org/10.1016/j.actamat.2016.06.064. http://www.sciencedirect.com/science/article/pii/S1359645416304955

Shahverdi H, Ghomashchi M, Shabestari S, Hejazi J (2002) Microstructural analysis of interfacial reaction between molten aluminium and solid iron. J Mater Process Technol 124(3):345–352. https://doi.org/10.1016/S0924-0136(02)00225-X. http://www.sciencedirect.com/science/article/pii/S092401360200225X

Peyre P, Sierra G, Deschaux-Beaume F, Stuart D, Fras G (2007) Generation of aluminium and steel joints with laser-induced reactive wetting. Mater Sci Eng A 444(1–2):327–338. https://doi.org/10.1016/j.msea.2006.09.111. http://www.sciencedirect.com/science/article/pii/S0921509306021411

Thomas W, Nicholas E, Needham J, Murch M, Temple-Smith P, Dawes C (1995) Friction welding, us patent 5,460,317. http://www.google.com/patents/US5460317

Kusuda Y (2013) Honda develops robotized fsw technology to weld steel and aluminum and applied it to a mass production vehicle. Industrial Robot: An International Journal 40(3):208–212. https://doi.org/10.1108/01439911311309889

Amini A, Asadi P, Zolghadr P (2014) 15 - Friction stir welding applications in industry. In: Givi MKB, Asadi P (eds) Advances in friction-stir welding and processing, woodhead publishing series in welding and other joining technologies. Woodhead Publishing, pp 671–722. https://doi.org/10.1533/9780857094551.671. http://www.sciencedirect.com/science/article/pii/B978085709454450015X

Kumar K, Kailas SV (2008) The role of friction stir welding tool on material flow and weld formation. Mater Sci Eng A 485(1):367–374. https://doi.org/10.1016/j.msea.2007.08.013. http://www.sciencedirect.com/science/article/pii/S0921509307015419

Sahu PK, Pal S, Pal SK, Jain R (2016) Influence of plate position, tool offset and tool rotational speed on mechanical properties and microstructures of dissimilar Al/Cu friction stir welding joints. J Mater Process Technol 235:55–67. https://doi.org/10.1016/j.jmatprotec.2016.04.014. http://www.sciencedirect.com/science/article/pii/S0924013616301042

Galvão I, Loureiro A, Verdera D, Gesto D, Rodrigues DM (2012) Influence of tool offsetting on the structure and morphology of dissimilar aluminum to copper friction-stir welds. Metall Mater Trans A 43(13):5096–5105. https://doi.org/10.1007/s11661-012-1351-x

Pourali M, Abdollah-zadeh A, Saeid T, Kargar F (2017) Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds. J Alloys Compd 715:1–8. https://doi.org/10.1016/j.jallcom.2017.04.272. http://www.sciencedirect.com/science/article/pii/S0925838817314822

Elyasi M, Derazkola HA, Hosseinzadeh M (2016) Investigations of tool tilt angle on properties friction stir welding of a441 aisi to aa1100 aluminium. Proc Inst Mech Eng B J Eng Manuf 230(7):1234–1241. https://doi.org/10.1177/0954405416645986

Bambach M, Göttmann A, Mertin C, Mosecker L, Naumov A (2013) Properties of friction stir welded blanks made from dc04 mild steel and aluminum aa6016. In: WGP Congress 2013, vol 769 of Advanced Materials Research, Trans Tech Publications, pp 237–244. https://doi.org/10.4028/www.scientific.net/AMR.769.237

Tanaka T, Morishige T, Hirata T (2009) Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloys. Scr Mater 61(7):756–759. https://doi.org/10.1016/j.scriptamat.2009.06.022. http://www.sciencedirect.com/science/article/pii/S1359646209004308

DebRoy T, Bhadeshia HKDH (2010) Friction stir welding of dissimilar alloys – a perspective. Sci Technol Weld Join 15(4):266–270. https://doi.org/10.1179/174329310X12726496072400

Lehto P, Romanoff J, Remes H, Sarikka T (2016) Characterisation of local grain size variation of welded structural steel. Welding in the World 60(4):673–688. https://doi.org/10.1007/s40194-016-0318-8

Gundersen HJG, Jensen EB (1985) Stereological estimation of the volume-weighted mean volume of arbitrary particles observed on random sections. J Microsc 138(2):127–142. https://doi.org/10.1111/j.1365-2818.1985.tb02607.x

Gundersen HJG, Jensen EB (1983) Particle sizes and their distributions estimated from line- and point-sampled intercepts, Including graphical unfolding. J Microsc 131(3):291–310. https://doi.org/10.1111/j.1365-2818.1983.tb04256.x

Dingley D (2004) Progressive steps in the development of electron backscatter diffraction and orientation imaging microscopy. J Microsc 213(3):214–224. https://doi.org/10.1111/j.0022-2720.2004.01321.x

Shimokawa T, Yamashita T, Niiyama T, Tsuji N (2016) Grain subdivision mechanism related to partial disclinations in severe plastic deformation: a molecular dynamics study. Mater Trans 57(9):1392–1398. https://doi.org/10.2320/matertrans.MH201518

Jaafar A, Rahmat A, Hussain Z, Zainol I (2011) Effect of Mg, Si and Cu content on the microstructure of dilute 6000 series aluminum alloys. J Alloys Compd 509(35):8632–8640. https://doi.org/10.1016/j.jallcom.2011.05.061. http://www.sciencedirect.com/science/article/pii/S0925838811011571

Hakamada M, Nakamoto Y, Matsumoto H, Iwasaki H, Chen Y, Kusuda H, Mabuchi M (2007) Relationship between hardness and grain size in electro-deposited copper films. Mater Sci Eng A 457(1-2):120–126. https://doi.org/10.1016/j.msea.2006.12.101

Taha AS, Hammad FH (1990) Application of the hall-petch relation to microhardness measurements on al, cu, al-md 105, and al-cu alloys. Phys Status Solidi (a) 119(2):455–462. https://doi.org/10.1002/pssa.2211190207

Lehto P, Remes H, Saukkonen T, Hänninen H, Romanoff J (2014) Influence of grain size distribution on the Hall–Petch relationship of welded structural steel. Mater Sci Eng A 592:28–39. https://doi.org/10.1016/j.msea.2013.10.094. http://www.sciencedirect.com/science/article/pii/S0921509313012094

Baudoin P, Magnier V, Bartali AE, Witz J-F, Dufrenoy P, Demilly F, Charkaluk E (2016) Numerical investigation of fatigue strength of grain size gradient materials under heterogeneous stress states in a notched specimen. Int J Fatigue 87:132–142. https://doi.org/10.1016/j.ijfatigue.2016.01.022. http://www.sciencedirect.com/science/article/pii/S0142112316000323

Khadyko M, Marioara C, Ringdalen I, Dumoulin S, Hopperstad O (2016) Deformation and strain localization in polycrystals with plastically heterogeneous grains. Int J Plast 86:128–150. https://doi.org/10.1016/j.ijplas.2016.08.005. http://www.sciencedirect.com/science/article/pii/S0749641916301401

Dunstan D, Bushby A (2014) Grain size dependence of the strength of metals: The Hall-Petch effect does not scale as the inverse square root of grain size. Int J Plast 53:56–65. https://doi.org/10.1016/j.ijplas.2013.07.004. http://www.sciencedirect.com/science/article/pii/S074964191300140X

Nicaise N, Berbenni S, Wagner F, Berveiller M, Lemoine X (2011) Coupled effects of grain size distributions and crystallographic textures on the plastic behaviour of IF steels. Int J Plast 27(2):232–249. https://doi.org/10.1016/j.ijplas.2010.05.001. http://www.sciencedirect.com/science/article/pii/S0749641910000665

Berbenni S, Favier V, Berveiller M (2007) Impact of the grain size distribution on the yield stress of heterogeneous materials. Int J Plast 23(1):114–142. https://doi.org/10.1016/j.ijplas.2006.03.004. http://www.sciencedirect.com/science/article/pii/S074964190600043X

Fonda RW, Knipling KE (2011) Texture development in friction stir welds. Sci Technol Weld Join 16(4):288–294. https://doi.org/10.1179/1362171811Y.0000000010

Abbasi M, Nelson TW, Sorensen CD (2012) Transformation and deformation texture study in friction stir processed API X80 pipeline steel. Metall and Mater Trans A 43(13):4940–4946. https://doi.org/10.1007/s11661-012-1356-5

Bachmann F, Hielscher R, Schaeben H (2010) Texture analysis with MTEX-free and open source software toolbox. Solid State Phenom 160:63–68. https://doi.org/10.4028/www.scientific.net/SSP.160.63

Acknowledgements

The authors would like to thank the German Research Foundation DFG for their continued support of our research within the Cluster of Excellence “Integrative Technologies for High Wage Countries”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Komerla, K., Naumov, A., Mertin, C. et al. Investigation of microstructure and mechanical properties of friction stir welded AA6016-T4 and DC04 alloy joints. Int J Adv Manuf Technol 94, 4209–4219 (2018). https://doi.org/10.1007/s00170-017-1022-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1022-6