Abstract

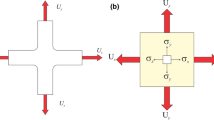

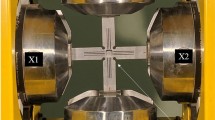

One of the most restricting aspects of the biaxial tensile test for sheet metal is the design of the cruciform specimen. Although specimens of the cruciform type have been investigated quite extensively previously, no standard geometry for the cruciform specimen exists. Using a specifically designed pantograph apparatus for operation in a standard tensile testing machine, various cruciform specimens machined from low-carbon cold rolled steel sheet were analysed experimentally. Finite element modelling of the specimens was conducted in parallel to the experimental test programme to establish optimum specimen geometry. Through a process of optimisation, a standard cruciform specimen was designed which can be used to accurately predict the mechanical behaviour of the mild steel when formed in multiple directions simultaneously. This paper describes the optimisation process and the results obtained from both the experimental testing and numerical modelling.

Similar content being viewed by others

References

Jones C (2001) Biaxial testing of polymer composites. Mater World 9(11):19–21

Demmerle S, Boehler JP (1993) Optimal design of biaxial tensile cruciform specimens. J Mech Phys Solid 41(1):143–181

Jones C, Green, R (2001) Pulled in different directions. Mater World 19–21

Ohtake Y, Rokugawa S, Masumoto H (1999) Geometry determination of cruciform type specimen and biaxial tensile test of C/C composites. Key Eng Mater 3:151–154

Xiang-Dong W, Wan M, Xian-Bin Z (2005) Biaxial tensile testing of cruciform specimen under complex loading. J Mater Process Technol 168:181–183

Lin SB, Ding JL, Zbib HM (1993) Characterization of yield surfaces using balanced biaxial tests of cruciform plate specimens. Scripta Metall Mater 28(5):617–622

Lin SB, Ding JL (1995) Experimental study of the plastic yielding of rolled sheet metals with the cruciform plate specimen. Int J Plast 11(5):583–604

Kuwabara T (2007) Advances in experiments on metal sheets and tubes in support of constitutive modeling and forming simulations. Int J Plast 23:385–419

Yong Y, Wan M, Xiang-Dong W, Xian-Bin Z (2002) Design of a cruciform biaxial tensile specimen for limit strain analysis by FEM. J Mat Proc Tech 123:67–79

Boehler JP, Demmerle S, Koss S (1994) A new direct biaxial testing machine for anisotropic materials. Exp Mech 34:1–9

Wu XD, Wan M, Xian-Bin Z (2005) Biaxial tensile testing of cruciform specimen under complex loading. J Mater Process Tech 168:181–183

Lin SB, Ding JL, Zbib HM (1993) Characterization of yield surfaces using balanced biaxial tests of cruciform plate specimens. Scr Metall Mater 28:617–622

Hanabusa Y, Takizawa H, Kuwabara T (2010) Evaluation of accuracy of stress measurements determined in biaxial stress tests with cruciform specimen using numerical method. Steel Res Int 81(9):1376–1378

Makinde A, Thibodeau L, Neale KW (1992) Development of an apparatus for biaxial testing of cruciform specimens. Exp Mech 32:138–144

Hannon A, Tiernan P (2008) A review of planar biaxial tensile test systems for sheet metal. J Mater Process Technol 198:1–13

Kuwabara T, Ikeda S, Kuroda K (1998) Measurement and analysis of differential work hardening in cold rolled steel sheet under biaxial tension. J Mat Proc Tech 80–81:517–523

Ferron G, Makinde A (1988) Design and development of a biaxial strength testing device. J Test Eval 16(3):253–256

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tiernan, P., Hannon, A. Design optimisation of biaxial tensile test specimen using finite element analysis. Int J Mater Form 7, 117–123 (2014). https://doi.org/10.1007/s12289-012-1105-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1105-8