Abstract

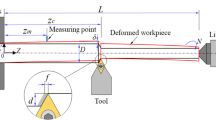

Many studies simulates the machining process by using a single degree of freedom spring-mass system to model the tool stiffness, or the workpiece stiffness, or the unit tool-workpiece stiffness in modelings 2D. Others impose the tool action, or use more or less complex modelings of the efforts applied by the tool taking account the tool geometry. Thus, all these models remain two-dimensional or sometimes partially three-dimensional. This paper aims at developing an experimental method allowing to determine accurately the real three-dimensional behaviour of a machining system (machine tool, cutting tool, tool-holder and associated system of force metrology six-component dynamometer). In the work-space model of machining, a new experimental procedure is implemented to determine the machining system elastic behaviour. An experimental study of machining system is presented. We propose a machining system static characterization. A decomposition in two distinct blocks of the system “Workpiece-Tool-Machine” is realized. The block Tool and the block Workpiece are studied and characterized separately by matrix stiffness and displacement (three translations and three rotations). The Castigliano’s theory allows us to calculate the total stiffness matrix and the total displacement matrix. A stiffness center point and a plan of tool tip static displacement are presented in agreement with the turning machining dynamic model and especially during the self induced vibration. These results are necessary to have a good three-dimensional machining system dynamic characterization (presented in a next paper).

Similar content being viewed by others

Abbreviations

- a:

-

Distance between displacement transducer

- BT :

-

Block Tool

- BW :

-

Block Workpiece

- [C]:

-

Damping matrix

- \({\left[C_{o}\right]}\) :

-

Compliance matrix

- C i :

-

Displacement transducer (i = 1 to 6)

- \(\textbf{CR}_{BT}\) :

-

Block Tool BT stiffness center

- D 1 :

-

Holding fixture diameter (mm)

- D 2 :

-

Workpiece diameter (mm)

- \(\left\{D\right\}\) :

-

Small displacements torsor

- D ij :

-

Straight line corresponding of the displacement direction of the point P i,j (i = x, y, z) and ( j=1, 2, 3)

- d i,j :

-

Points displacements vectors P i,j (i = x, y, z) and ( j=1, 2, 3)

- d x :

-

Distance between the line D ij

- E :

-

Young modulus (N/mm2)

- e x , f x :

-

Scale factors

- F i :

-

Force vectors applied to obtain BT stiffness center (i = x, y, z)

- I:

-

Inertial moment

- \({\left[K\right]}\) :

-

Stiffness matrix (N/m)

- \({\left[K_{C}\right]}\) :

-

Stiffness matrix of rotation (Nm/rad)

- \({\left[K_{F}\right]}\) :

-

Stiffness matrix of displacement (N/m)

- \({\left[K_{F,BT}\right]}\) :

-

Stiffness matrix of BT displacement (N/m)

- \({\left[K_{F,BW}\right]}\) :

-

Stiffness matrix of BW displacement (N/m)

- \({\left[K_{F,WAM}\right]}\) :

-

Stiffness matrix of machining system displacement (N/m)

- \({\left[K_{errors}(\textrm{\%})\right]}\) :

-

Errors matrix for the matrix \(\left[K\right]\)

- \({\left[K_{CF}\right]}\) :

-

Stiffness matrix of rotation / displacement (Nm/m)

- \({\left[K_{FC}\right]}\) :

-

Stiffness matrix of displacement/rotation (N/rad)

- L 1 :

-

Holding fixture length (mm)

- L 2 :

-

Length workpiece (mm)

- M i :

-

Point intersection between straight lines (Dij)(i = x, y, z) and ( j=1, 2, 3)

- m :

-

Displacement measured at the charge point

- \({\left[M\right]}\) :

-

Mass matrix

- n i :

-

Plan normal P i

- O :

-

Tool tip point

- O c :

-

Cub center

- P :

-

Force (N)

- P i :

-

Plan including the point M i

- \(\textbf{P}_{BT}\) :

-

Displacement plan considering tool point

- P ij :

-

Charge points (i = x, y, z) and ( j=1, 2, 3)

- \(\left\{T\right\}\) :

-

Mechanical actions torsor

- \({\left[V\right]}\) :

-

Matrix eigenvector \(\left[K_{F,BT}\right]\)

- v 1 :

-

Matrix eigenvalue \(\left[K_{F,BT}\right]\)

- WTM :

-

Workpiece-Tool-Machine

- x (z):

-

Cross (feed) direction

- y:

-

Cutting axis

- δ :

-

Displacement (mm)

- ϵ i :

-

Displacement along i (i=1,2,3)

- θ :

-

Measured angle at the force point

- θ i :

-

Angular deviation of “Co-planarity” between lines Dij (i = x, y, z; and j = 1, 2, 3)

- μ i :

-

Minimal distance between straight lines Dij (i = x, y, z; and j=1, 2, 3)

- ρ i :

-

Rotation along i (i=x, y, z)

References

Axinte DA, Belluco W, De Chiffre L (2001) Evaluation of cutting force uncertainty components in turning. Int J Mach Tools Manuf 41:719–730

Benardos PG, Mosialos S, Vosniakos GC (2006) Prediction of workpiece elastic deflections under cutting forces in turning. Robot Comput-Integr Manuf 22:505–514

Bisu CF (2007) Etude des vibrations auto-entretenues en coupe tridimensionnelle: nouvelle modélisation appliquée au tournage. Ph.D. Thesis. Université Bordeaux 1 and Universitatea Politehnica Bucharest

Bisu CF, Darnis P, Gérard A, K’nevez J-Y (2008) Displacements analysis of self-excited vibrations in turning. Int J Adv Manuf Technol. doi:10.1007/s00170-008-1815-8

Buyuksagis IS (1998) Analysis of circular marble sawing using a block-cutter, Ph.D. Thesis. Osmangazi University, Institute of Sciences and Technology

Cano T, Chapelle F, Lavest J-M, Ray P (2008) A new approach to identifying the elastic behaviour of a manufacturing machine. Int J Mach Tools Manuf 48:1569–1577

Cardi AA, Firpi HA, Bement MT, Liang SY (2008) Workpiece dynamic analysis and prediction during chatter of turning process. Mech Syst Signal Process 22:1481–1494

Carrino L, Giorleo G, Polini W, Prisco U (2002) Dimensional errors in longitudinal turning based on the unified generalized mechanics of cutting approach. Part I: three-dimensional theory. Int J Mach Tools Manuf 42:1509–1515

Casrto LR, Viéville P, Lipinski P (2006) Correction of dynamic effects on force measurements made wqwith piezoelectric dynamometers. Int J Mach Tools Manuf 46(14):1707–1715

Chen CK, Tsao YM (2006) A stability analysis of regenerative chatter in turning process without using tailstock. Int J Adv Manuf Technol 29(7–8):648–654

Chen CK, Tsao YM (2006) A stability analysis of turning tailstock supported flexible work-piece. Int J Mach Tools Manuf 46(1):18–25

Couétard Y (2000) Caractérisation et étalonnage des dynamomètres à six composantes pour torseur associé à un système de forces, Ph. D. Thesis. Université Bordeaux 1 Talence

Dassanayake AV, Suh CS (2008) On nonlinear cutting response and tool chatter in turning operation. Commun Nonlinear Sci Numer Simul 13(5):979–1001

Deacu I, Pavel G (1977) Vibrations des machines-outils. Dacia, Cluj Napoca

Dimla Sr DE (2004) The impact of cutting conditions on cutting forces and vibration signals in turning with plane face geometry inserts. J Mater Process Technol 155–156:1708–1715

Ganguli A, Deraemaeker A, Preumont A (2007) Regenerative chatter reduction by active damping control. J Sound Vib 300:847–862

Gorodetskii YI, Budankov AS, Komarov VN (2008) A system for experimental studies of the dynamics of the process of cutting metal. J Mach Manuf Reliab 37(1):68–73

Insperger T, Barton DAW, Stepan G (2008) Criticality of Hopf bifucation in state-dependent delay model turning processes. Int J Non-linear Mech 43:140–149

Ispas C, Gheorghiu H, Parausanu I, Anghel V (1999) Vibrations des systèmes technologiques. Agir, Bucarest

Karabay S (2007) Design criteria for electro-mechanical transducers and arrangement for measurement cutting forces acting on dynamometers. Mater Des 28:496–506

Koenigsberger F, Tlusty J (1970) Machine tools structures. Pergamon, Oxford

Konig W, Sepulveda E, Lauer-Schmaltz H (1997) Zweikomponenten schnittkraftmesser. Industrie-Anzeiger

Korkut I (1996) Design and manufacturing of a dynamometer connected to computer which can do measuring with strain gages on the lathe, Ph.D. Thesis. University of Gazi, Institute of Science and Technology

Kudinov VA (1970) Dinamica masinilor unelten. Tehnicas, Bucarest

Lapujoulade F, Coffignal G, Pimont J (1998) Cutting forces evaluation during high speed milling, 2th IDMME’ 98, vol 2, pp 541–549. Compiègne, France, May

Marinescu I, Ispas C, Boboc D (2002) Handbook of machine tool analysis. Deckker M., New York

Mehdi K, Rigal J-F, Play D (2002) Dynamic behavior of thin wall cylindrical workpiece during the turning process, Part 1: cutting process simulation. J Manuf Sci Eng 124:562–568

Pérez H, Vizán A, Hernandez JC, Guzmán M (2007) Estimation of cutting forces in micromilling through the determination of specific cutting pressures. J Mater Process Technol 190:18–22

Pestel EC, Leckie FA (1963) Matrix methods in elastomechanics. McGraw-Hill, New York

Robinson J (1971) Analyse matricielle des structures à l’usage des ingénieurs. Dunod, Paris

Saglam H, Unsacar F, Yaldiz S (2006) Investigation of the effect of rake angle and approaching angle on main cutting force and tool tip temperature. Int J Mach Tools Manuf 46(2):132–141

Saglam H, Yaldiz S, Unsacar F (2002) The effect of tool geometry and cutting speed on main cutting force and tool tip temperature. Mater Des 28:355–360

Salgado MA, López de Lacalle LN, Lamikiz A, Munoa J, Sánchez JA (2005) Evaluation of the stiffness chain on the deflection of end-mills under cutting forces. Int J Mach Tools Manuf 45:727–739

Sekar M, Srinivas J, Kotaiah KR, Yang SH (2008) Stability analysis of turning process with tailstock-supported workpiece. Int J Adv Manuf Technol. doi:10.1007/s00170-0008-1764-2

Seker U, Kurt A, Ciftci I (2004) The effect of feed rate on the cutting forces when machining with linear motion. J Mat Proc Tech 146:403–407

Toh CK (2004) Static and dynamic cutting force analysis when high speed rough milling hardened steel. Mater Des 25:41–50

Toulouse D (1998) Contribution à la modélisation et à la métrologie de la coupe dans le cas d’un usinage tridimensionnel, Ph. D. Thesis. Université Bordeaux 1 Talence

Wang ZC, Cleghorn WL (2002) Stability analysis of spinning stepped-shaft workpieces in a turning process. J Sound Vib 250(2):356–367

Yaldiz S, Ünsacar F (2006) Design, development and testing of a turning dynamometer for cutting force measurement. Mater Des 27:839–846

Yaldiz S, Ünsacar F (2006) A dynamometer design for measurement the cutting forces on turning. Measurement 39:80–89

Yaldiz S, Ünsacar F, Saglam H (2006) Comparaison of experimental results obtained by designed dynamometer to fuzzy model for predicting cutting forces in turning. Mater Des 27:1139–1147

Acknowledgements

The authors acknowledge Jean Pierre Larivière, Ingineer CNRS (Centre National de la Recherche Scintifique - France) for the numerical simulation with SAMCEF software and Professor Miron Zapciu for the helpful discussions on this subject.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bisu, C.F., K’nevez, JY., Darnis, P. et al. New method to characterize a machining system: application in turning. Int J Mater Form 2, 93–105 (2009). https://doi.org/10.1007/s12289-009-0395-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-009-0395-y