Abstract

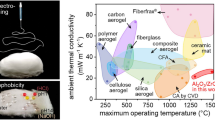

Energy efficient buildings require novel thermal insulators accompanied by lightweight, mechanically robust, fire resistant, and low thermal conductivity. Ceramic fibrous aerogels have emerged as promising candidates, however it’s difficult for these materials to achieve exceptional mechanical and thermal insulation performance simultaneously. Here, we demonstrate a unique semi-template method to fabricate biomimetic-architectured silica/carbon dual-fibrous aerogel with robust mechanical performance. Specifically, aerogels with honeycomb-like cellular and nanofiber/nanonet cell wall were constructed by freezedrying the homogeneous dispersion of SiO2 nanofibers and cellulose nanofibers co-suspensions. It is worth noting that the biomimetic structure has been perfectly inherited even subjected to high-temperature carbonization. As a result, the excellent structural stability brought by the novel structure enables the aerogel to completely recover under large compression and buckling strain of 80%, and exhibit robust fatigue resistance over 200,000 cycles. More importantly, the aerogels exhibit ultralow thermal conductivity (0.023 W·m−1·K−1), superior flame retardancy, together with excellent thermal insulation performance over a wide temperature ranging from −196 to 350 °C. The fabrication of such materials may provide new ideas for the development of next-generation thermal insulators for harsh conditions.

Similar content being viewed by others

References

Kistler, S. S. Coherent expanded aerogels and jellies. Nature 1931, 127, 741–741.

Wu, X. L.; Wen, T.; Guo, H. L.; Yang, S. B.; Wang, X. K.; Xu, A. W. Biomass-derived sponge-like carbonaceous hydrogels and aerogels for supercapacitors. ACS Nano 2013, 7, 3589–3597.

Xu, W. Z.; Xing, Y.; Liu, J.; Wu, H. P.; Cui, Y.; Li, D. W.; Guo, D. Y.; Li, C. R.; Liu, A. P.; Bai, H. Efficient water transport and solar steam generation via radially, hierarchically structured aerogels. ACS Nano 2019, 13, 7930–7938.

He, Y. L.; Xie, T. Advances of thermal conductivity models of nanoscale silica aerogel insulation material. Appl. Therm. Eng. 2015, 81, 28–50.

Wei, G. S.; Liu, Y. S.; Zhang, X. X.; Yu, F.; Du, X. Z. Thermal conductivities study on silica aerogel and its composite insulation materials. Int. J. Heat Mass Transfer 2011, 54, 2355–2366.

He, S.; Huang, Y. J.; Chen, G. N.; Feng, M. M.; Dai, H. M.; Yuan, B. H.; Chen, X. F. Effect of heat treatment on hydrophobic silica aerogel. J. Hazard. Mater. 2019, 362, 294–302.

Zu, Y. F.; Sha, J. J.; Li, J.; Zhang, Z. F.; Wang, S. H.; Lv, Z. Z.; Dai, J. X. Effect of multi-walled carbon nanotubes on microstructure and fracture properties of carbon fiber-reinforced ZrB2-based ceramic composite. Ceram. Int. 2017, 43, 7454–7460.

Jiang, R.; Yang, L. W.; Liu, H. T.; Sun, X.; Cheng, H. F. High-temperature mechanical properties of nextel™ 610 fiber reinforced silica matrix composites. Ceram. Int. 2018, 44, 15356–15361.

Zhang, J.; Fan, J. P.; Zhang, J. Y.; Zhou, J.; Liu, X. M.; Qie, D. C.; Zhang, D. H. Developing and preparing interfacial coatings for high tensile strength silicon nitride fiber reinforced silica matrix composites. Ceram. Int. 2018, 44, 5297–5303.

Hu, P.; Cheng, Y.; Wang, P.; Guo, X.; Ma, C.; Qu, Q.; Zhang, X. H.; Du, S. Y. Rolling compacted fabrication of carbon fiber reinforced ultra-high temperature ceramics with highly oriented architectures and exceptional mechanical feedback. Ceram. Int. 2018, 44, 14907–14912.

Yu, H. J.; Jiang, Y. T.; Lu, Y. F.; Li, X. L.; Zhao, H. Y.; Ji, Y. C.; Wang, M. J. Quartz fiber reinforced Al2O3-SiO2 aerogel composite with highly thermal stability by ambient pressure drying. J. Non-Cryst. Solids 2019, 505, 79–86.

Dourbash, A.; Buratti, C.; Belloni, E.; Motahari, S. Preparation and characterization of polyurethane/silica aerogel nanocomposite materials. J. Appl. Polym. Sci. 2017, 134, 44521.

Mao, X.; Si, Y.; Chen, Y. C.; Yang, L. P.; Zhao, F.; Ding, B.; Yu, J. Y. Silica nanofibrous membranes with robust flexibility and thermal stability for high-efficiency fine particulate filtration. RSC Adv. 2012, 2, 12216–12223.

An, Z. M.; Ye, C. S.; Zhang, R. B.; Zhou, P. Flexible and recoverable SiC nanofiber aerogels for electromagnetic wave absorption. Ceram. Int. 2019, 45, 22793–22801.

Yan, J. H.; Han, Y. H.; Xia, S. H.; Wang, X.; Zhang, Y. Y.; Yu, J. Y.; Ding, B. Polymer template synthesis of flexible BaTiO3 crystal nanofibers. Adv. Funct. Mater. 2019, 29, 1907919.

Meza, L. R.; Das, S.; Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 2014, 345, 1322–1326.

Su, L.; Wang, H. J.; Niu, M.; Fan, X. Y.; Ma, M. B.; Shi, Z. Q.; Guo, S. W. Ultralight, recoverable, and high-temperature-resistant SiC nanowire aerogel. ACS Nano 2018, 12, 3103–3111.

Su, L.; Li, M. Z.; Wang, H. J.; Niu, M.; Lu, D.; Cai, Z. X. Resilient Si3N4 Nanobelt Aerogel as fire-resistant and electromagnetic wave-transparent thermal insulator. ACS Appl. Mater. Interfaces 2019, 11, 15795–15803.

Xu, X.; Zhang, Q. Q.; Hao, M. L.; Hu, Y.; Lin, Z. Y.; Peng, L. L.; Wang, T.; Ren, X. X.; Wang, C.; Zhao, Z. P. et al. Double-negativeindex ceramic aerogels for thermal superinsulation. Science 2019, 363, 723–727.

Wicklein, B.; Diem, A. M.; Knöller, A.; Cavalcante, M. S.; Bergström, L.; Bill, J.; Burghard, Z. Dual-fiber approach toward flexible multifunctional hybrid materials. Adv. Funct. Mater. 2018, 28, 1704274.

Si, Y.; Wang, X. Q.; Dou, L. Y.; Yu, J. Y.; Ding, B. Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity. Sci. Adv. 2018, 4, eaas8925.

Wang, F.; Dou, L. Y.; Dai, J. W.; Li, Y. Y.; Huang, L. Q.; Si, Y.; Yu, J. Y.; Ding, B. In situ synthesis of biomimetic silica nanofibrous aerogels with temperature-invariant superelasticity over one million compressions. Angew. Chem., Int. Ed. 2020, 59, 8285–8292.

Zhang, X. X.; Wang, F.; Dou, L. Y.; Cheng, X. T.; Si, Y.; Yu, J. Y.; Ding, B. Ultrastrong, superelastic, and lamellar multiarch structured ZrO2-Al2O3 nanofibrous aerogels with high-temperature resistance over 1300 °C. ACS Nano 2020, 14, 15616–15625.

Yang, M.; Zhao, N. F.; Cui, Y.; Gao, W. W.; Zhao, Q.; Gao, C.; Bai, H.; Xie, T. Biomimetic architectured graphene aerogel with exceptional strength and resilience. ACS Nano 2017, 11, 6817–6824.

Cui, Y.; Gong, H. X.; Wang, Y. J.; Li, D. W.; Bai, H. A thermally insulating textile inspired by polar bear hair. Adv. Mater. 2018, 30, 1706807.

Jiang, B.; Chen, C. J.; Liang, Z. Q.; He, S. M.; Kuang, Y. D.; Song, J. W.; Mi, R. Y.; Chen, G. G.; Jiao, M. L.; Hu, L. B. Lignin as a wood-inspired binder enabled strong, water stable, and biodegradable paper for plastic replacement. Adv. Funct. Mater. 2020, 30, 1906307.

Yu, Z. L.; Qin, B.; Ma, Z. Y.; Gao, Y. C.; Guan, Q. F.; Yang, H. B.; Yu, S. H. Emerging bioinspired artificial woods. Adv. Mater. 2021, 33, 2001086.

Chen, C. J.; Li, Z. H.; Mi, R. Y.; Dai, J. Q.; Xie, H.; Pei, Y.; Li, J. G.; Qiao, H. Y.; Tang, H.; Yang, B. et al. Rapid processing of whole bamboo with exposed, aligned nanofibrils toward a highperformance structural material. ACS Nano 2020, 14, 5194–5202.

Ajdari, A.; Jahromi, B. H.; Papadopoulos, J.; Nayeb-Hashemi, H.; Vaziri, A. Hierarchical honeycombs with tailorable properties. Int. J. Solids Struct. 2012, 49, 1413–1419.

Wang, J.; Liu, J. L.; Chao, D. L.; Yan, J. X.; Lin, J. Y.; Shen, Z. X. Self-assembly of honeycomb-like MoS2 nanoarchitectures anchored into graphene foam for enhanced lithium-ion storage. Adv. Mater. 2014, 26, 7162–7169.

Dong, K.; Liang, J.; Wang, Y. Y.; Xu, Z. Q.; Liu, Q.; Luo, Y. L.; Li, T. S.; Li, L.; Shi, X. F.; Asiri, A. M. et al. Honeycomb carbon nanofibers: A superhydrophilic O2-entrapping electrocatalyst enables ultrahigh mass activity for the two-electron oxygen reduction reaction. Angew. Chem., Int. Ed. 2021, 60, 10583–10587.

Cho, S. J.; Kim, B. S.; Min, D. K.; Cho, Y. S.; Park, J. H. Honeycomb-shaped meta-structure for minimizing noise radiation and resistance to cooling fluid flow of home appliances. Compos. Struct. 2016, 155, 1–7.

Lin, Y. L.; Zhang, Z. F.; Chen, R.; Li, Y.; Wen, X. J.; Lu, F. Y. Cushioning and energy absorbing property of combined aluminum honeycomb. Adv. Eng. Mater. 2015, 17, 1434–1441.

Cho, M. W.; Kim, J.; Jeong, J. M.; Yim, B.; Lee, H. J.; Yoo, Y. Excellent toluene removal via adsorption by honeycomb adsorbents under high temperature and humidity conditions. Environ. Eng. Res. 2020, 25, 171–177.

Berkefeld, A.; Heyer, M.; Milow, B. Silica aerogel paper honeycomb composites for thermal insulations. J. Sol-Gel Sci. Technol. 2017, 84, 486–495.

Ge, J. L.; Zong, D. D.; Jin, Q.; Yu, J. Y.; Ding, B. Biomimetic and superwettable nanofibrous skins for highly efficient separation of oil-in-water emulsions. Adv. Funct. Mater. 2018, 28, 1705051.

Huang, J.; Lei, Y.; Wang, L. L.; Yan, T. T.; Liu, J. K.; Chen, Q. H. Preparation of hydroxyapatite whisker honeycomb scaffolds via foaming method. J. Synth. Cryst. 2016, 45, 2862–2865.

Hou, X. S.; Zhu, G. L.; Ren, L. J.; Huang, Z. H.; Zhang, R. B.; Ungar, G.; Yan, L. T.; Wang, W. Mesoscale graphene-like honeycomb mono- and multilayers constructed via self-assembly of coclusters. J. Am. Chem. Soc. 2018, 140, 1805–1811.

Deville, S. Ice-templating, freeze casting: Beyond materials processing. J. Mater. Res. 2013, 28, 2202–2219.

Li, W. L.; Lu, K.; Walz, J. Y. Freeze casting of porous materials: Review of critical factors in microstructure evolution. Int. Mater. Rev. 2012, 57, 37–60.

Shao, G. F.; Hanaor, D. A. H.; Shen, X. D.; Gurlo, A. Freeze casting: From low-dimensional building blocks to aligned porous structures-a review of novel materials, methods, and applications. Adv. Mater. 2020, 32, 1907176.

Li, G. Y.; Zhu, M. Y.; Gong, W. B.; Du, R.; Eychmüller, A.; Li, T. T.; Lv, W. B.; Zhang, X. T. Boron nitride aerogels with super-flexibility ranging from liquid nitrogen temperature to 1000 °C. Adv. Funct. Mater. 2019, 29, 1900188.

Tang, N.; Zhang, S. C.; Si, Y.; Yu, J. Y.; Ding, B. An ultrathin bacterial cellulose membrane with a voronoi-net structure for low pressure and high flux microfiltration. Nanoscale 2019, 17, 17851–17859.

Li, C.; Ding, Y. W.; Hu, B. C.; Wu, Z. Y.; Gao, H. L.; Liang, H. W.; Chen, J. F.; Yu, S. H. Temperature-invariant superelastic and fatigue resistant carbon nanofiber aerogels. Adv. Mater. 2020, 32, 1904331.

Su, L.; Wang, H. J.; Niu, M.; Dai, S.; Cai, Z. X.; Yang, B. G.; Huyan, H. X.; Pan, X. Q. Anisotropic and hierarchical SiC@SiO2 nanowire aerogel with exceptional stiffness and stability for thermal superinsulation. Sci. Adv. 2020, 6, eaay6689.

Qiu, L.; Liu, J. Z.; Chang, S. L. Y.; Wu, Y. Z.; Li, D. Biomimetic superelastic graphene-based cellular monoliths. Nat. Commun. 2012, 3, 1241.

Gao, H. L.; Zhu, Y. B.; Mao, L. B.; Wang, F. C.; Luo, X. S.; Liu, Y. Y.; Lu, Y.; Pan, Z.; Ge, J.; Shen, W. et al. Super-elastic and fatigue resistant carbon material with lamellar multi-arch microstructure. Nat. Commun. 2016, 7, 12920.

Wang, H. L.; Zhang, X.; Wang, N.; Li, Y.; Feng, X.; Huang, Y.; Zhao, C. S.; Liu, Z. L.; Fang, M. H.; Ou, G. et al. Ultralight, scalable, and high-temperature-resilient ceramic nanofiber sponges. Sci. Adv. 2017, 3, e1603170.

Xu, C. C.; Wang, H. L.; Song, J. A.; Bai, X. P.; Liu, Z. L.; Fang, M. H.; Yuan, Y. S.; Sheng, J. Y.; Li, X. Y.; Wang, N. et al. Ultralight and resilient Al2O3 nanotube aerogels with low thermal conductivity. J. Am. Ceram. Soc. 2018, 101, 1677–1683.

Cao, L. T.; Si, Y.; Wu, Y. Y.; Wang, X. Q.; Yu, J. Y.; Ding, B. Ultralight, superelastic and bendable lashing-structured nanofibrous aerogels for effective sound absorption. Nanoscale 2019, 17, 2289–2298.

Li, Y. Y.; Cao, L. T.; Yin, X.; Si, Y.; Yu, J. Y.; Ding, B. Semi-interpenetrating polymer network biomimetic structure enables superelastic and thermostable nanofibrous aerogels for cascade filtration of PM2.5. Adv. Funct. Mater. 2020, 30, 1910426.

Stojcevski, F.; Hilditch, T. B.; Gengenbach, T. R.; Henderson, L. C. Effect of carbon fiber oxidization parameters and sizing deposition levels on the fiber-matrix interfacial shear strength. Compos. Part A Appl. Sci. Manuf. 2018, 114, 212–224.

Zhang, X.; Zhao, X. Y.; Xue, T. T.; Yang, F.; Fan, W.; Liu, T. X. Bidirectional anisotropic polyimide/bacterial cellulose aerogels by freeze-drying for super-thermal insulation. Chem. Eng. J. 2020, 385, 123963.

Lee, O. J.; Lee, K. H.; Yim, T. J.; Kim, S. Y.; Yoo, K. P. Determination of mesopore size of aerogels from thermal conductivity measurements. J. Non-Cryst. Solids 2002, 298, 287–292.

Hayase, G.; Kugimiya, K.; Ogawa, M.; Kodera, Y.; Kanamori, K.; Nakanishi, K. The thermal conductivity of polymethylsilsesquioxane aerogels and xerogels with varied pore sizes for practical application as thermal superinsulators. J. Mater. Chem. A 2014, 2, 6525–6531.

Li, T.; Song, J. W.; Zhao, X. P.; Yang, Z.; Pastel, G.; Xu, S. M.; Jia, C.; Dai, J. Q.; Chen, C. J.; Gong, A. et al. Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose. Sci. Adv. 2018, 4, eaar3724.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51925302, 21961132024, and 51873029), the Science and Technology Commission of Shanghai Municipality (No. 20QA1400500), China Postdoctoral Science Foundation (Nos. 2021TQ0163 and 2021M101821), and Shuimu Tsinghua Scholar Program.

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

12274_2022_4194_MOESM1_ESM.pdf

Semi-template based, biomimetic-architectured, and mechanically robust ceramic nanofibrous aerogels for thermal insulation

Rights and permissions

About this article

Cite this article

Dou, L., Si, Y., Yu, J. et al. Semi-template based, biomimetic-architectured, and mechanically robust ceramic nanofibrous aerogels for thermal insulation. Nano Res. 15, 5581–5589 (2022). https://doi.org/10.1007/s12274-022-4194-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-022-4194-9