Abstract

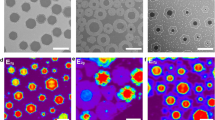

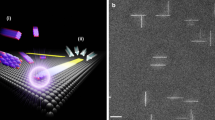

In the chemical vapor deposition growth of large-area graphene polycrystalline thin films, the coalescence of randomly oriented graphene domains results in a high density of uncertain grain boundaries (GBs). The structures and properties of various GBs are highly dependent on the misorientation angles between the graphene domains, which can significantly affect the performance of the graphene films and impede their industrial applications. Graphene bicrystals with a specific type of GB can be synthesized via the controllable growth of graphene domains with a predefined lattice orientation. Although the bicrystal has been widely investigated for traditional bulk materials, no successful synthesis strategy has been presented for growing two-dimensional graphene bicrystals. In this study, we demonstrate a simple approach for growing well-aligned large-domain graphene bicrystals with a confined tilt angle of 30° on a facilely recrystallized single-crystal Cu (100) substrate. Control of the density of the GBs with a misorientation angle of 30° was realized via the controllable rapid growth of subcentimeter graphene domains with the assistance of a cooperative catalytic surface-passivation treatment. The large-area production of graphene bicrystals consisting of the sole specific GBs with a tunable density provides a new material platform for fundamental studies and practical applications.

Similar content being viewed by others

References

Castro Neto, A. H.; Guinea, F.; Peres, N. M. R.; Novoselov, K. S.; Geim, A. K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162.

Addou, R.; Batzill, M. Defects and domain boundaries in self-assembled terephthalic acid (TPA) monolayers on CVD-grown graphene on Pt (111). Langmuir 2013, 29, 6354–6360.

Huang, P. Y.; Ruiz-Vargas, C. S.; van der Zande, A. M.; Whitney, W. S.; Levendorf, M. P.; Kevek, J. W.; Garg, S.; Alden, J. S.; Hustedt, C. J.; Zhu, Y. et al. Grains and grain boundaries in single-layer graphene atomic patchwork quilts. Nature 2011, 469, 389–392.

Duong, D. L.; Han, G. H.; Lee, S. M.; Gunes, F.; Kim, E. S.; Kim, S. T.; Kim, H.; Ta, Q. H.; So, K. P.; Yoon, S. J. et al. Probing graphene grain boundaries with optical microscopy. Nature 2012, 490, 235–239.

Lee, G.-H.; Cooper, R. C.; An, S. J.; Lee, S.; van der Zande, A.; Petrone, N.; Hammerberg, A. G.; Lee, C.; Crawford, B.; Oliver, W. High-strength chemical-vapor-deposited graphene and grain boundaries. Science 2013, 340, 1073–1076.

Carlsson, J. M.; Ghiringhelli, L. M.; Fasolino, A. Theory and hierarchical calculations of the structure and energetics of [0001]_tilt grain boundaries in graphene. Phys. Rev. B 2011, 84, 165423.

Rasool, H. I.; Ophus, C.; Klug, W. S.; Zettl, A.; Gimzewski, J. K. Measurement of the intrinsic strength of crystalline and polycrystalline graphene. Nat. Commun. 2013, 4, 2811.

Zhang, X. Y.; Xu, Z. W.; Yuan, Q. H.; Xin, J.; Ding, F. The favourable large misorientation angle grain boundaries in graphene. Nanoscale 2015, 7, 20082–20088.

Yazyev, O. V.; Chen, Y. P. Polycrystalline graphene and other two-dimensional materials. Nat. Nanotechnol. 2014, 9, 755–767.

Wood, J. D.; Schmucker, S. W.; Lyons, A. S.; Pop, E.; Lyding, J. W. Effects of polycrystalline cu substrate on graphene growth by chemical vapor deposition. Nano Lett. 2011, 11, 4547–4554.

Kim, K.; Lee, Z.; Regan, W.; Kisielowski, C.; Crommie, M. F.; Zettl, A. Grain boundary mapping in polycrystalline graphene. ACS Nano 2011, 5, 2142–2146.

Li, X. S.; Cai, W. W.; An, J.; Kim, S.; Nah, J.; Yang, D. X.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E. et al. Largearea synthesis of high-quality and uniform graphene films on copper foils. Science 2009, 324, 1312–1314.

Lin, P.; Palumbo, G.; Harase, J.; Aust, K. T. Coincidence site lattice (CSL) grain boundaries and Goss texture development in Fe-3% Si alloy. Acta Mater. 1996, 44, 4677–4683.

Gertsman, V. Y.; Bruemmer, S. M. Study of grain boundary character along intergranular stress corrosion crack paths in austenitic alloys. Acta Mater. 2001, 49, 1589–1598.

Chun, H.; Na, S.-M.; Mudivarthi, C.; Flatau, A. B. The role of misorientation and coincident site lattice boundaries in Goss-textured Galfenol rolled sheet. J. Appl. Phys. 2010, 107, 09A960.

Saylor, D. M.; Rohrer, G. S. Measuring the influence of grain-boundary misorientation on thermal groove geometry in ceramic polycrystals. J. Am. Ceram. Soc. 1999, 82, 1529–1536.

Sato, Y.; Yamamoto, T.; Ikuhara, Y. Atomic structures and electrical properties of ZnO grain boundaries. J. Am. Ceram. Soc. 2007, 90, 337–357.

Todt, V. R.; Zhang, X. F.; Miller, D. J.; St. Louis-Weber, M.; Dravid, V. P. Controlled growth of bulk bicrystals and the investigation of microstructure-property relations of YBa2Cu3Ox grain boundaries. App. Phys. Lett. 1996, 69, 3746–3748.

Fan, Z. X.; Huang, X.; Han, Y.; Bosman, M.; Wang, Q. X.; Zhu, Y. H.; Liu, Q.; Li, B.; Zeng, Z. Y.; Wu, J. et al. Surface modification-induced phase transformation of hexagonal close-packed gold square sheets. Nat. Commun. 2015, 6, 6571.

Yuan, Q. H.; Song, G. Y.; Sun, D. Y.; Ding, F. Formation of graphene grain boundaries on Cu(100) surface and a route towards their elimination in chemical vapor deposition growth. Sci. Rep. 2014, 4, 6541.

Wang, H.; Xu, X. Z.; Li, J. Y.; Lin, L.; Sun, L. Z.; Sun, X.; Zhao, S. L.; Tan, C. W.; Chen, C.; Dang, W. H. et al. Surface monocrystallization of copper foil for fast growth of large single-crystal graphene under free molecular flow. Adv. Mater. 2016, 28, 8968–8974.

Barrett, C. S.; Massalski, T. B. Structure of Metals; Pergamon: New York, 1980.

Lin, L.; Li, J. Y.; Ren, H. Y.; Koh, A. L.; Kang, N.; Peng, H. L.; Xu, H. Q.; Liu, Z. F. Surface engineering of copper foils for growing centimeter-sized single-crystalline graphene. ACS Nano 2016, 10, 2922–2929.

Lin, L.; Sun, L. Z.; Zhang, J. C.; Sun, J. Y.; Koh, A. L.; Peng, H. L.; Liu, Z. F. Rapid growth of large single-crystalline graphene via second passivation and multistage carbon supply. Adv. Mater. 2016, 28, 4671–4677.

Wu, T. R.; Zhang, X. F.; Yuan, Q. H.; Xue, J. C.; Lu, G. Y.; Liu, Z. H.; Wang, H. S.; Wang, H. M.; Ding, F.; Yu, Q. K. et al. Fast growth of inch-sized single-crystalline graphene from a controlled single nucleus on Cu-Ni alloys. Nat. Mater. 2016, 15, 43–47.

Lee, J.-H.; Lee, E. K.; Joo, W.-J.; Jang, Y.; Kim, B.-S.; Lim, J. Y.; Choi, S.-H.; Ahn, S. J.; Ahn, J. R.; Park, M.-H. et al. Wafer-scale growth of single-crystal monolayer graphene on reusable hydrogen-terminated germanium. Science 2014, 344, 286–289.

Nie, S.; Wofford, J. M.; Bartelt, N. C.; Dubon, O. D.; McCarty, K. F. Origin of the mosaicity in graphene grown on Cu(111). Phys. Rev. B 2011, 84, 155425.

Murdock, A. T.; Koos, A.; Britton, T. B.; Houben, L.; Batten, T.; Zhang, T.; Wilkinson, A. J.; Dunin-Borkowski, R. E.; Lekka, C. E.; Grobert, N. Controlling the orientation, edge geometry, and thickness of chemical vapor deposition graphene. ACS Nano 2013, 7, 1351–1359.

Merchant, H. D.; Liu, W. C.; Giannuzzi, L. A.; Morris, J. G. Grain structure of thin electrodeposited and rolled copper foils. Mater. Charact. 2004, 53, 335–360.

Wilson, N. R.; Marsden, A. J.; Saghir, M.; Bromley, C. J.; Schaub, R.; Costantini, G.; White, T. W.; Partridge, C.; Barinov, A.; Dudin, P. et al. Weak mismatch epitaxy and structural feedback in graphene growth on copper foil. Nano Res. 2013, 6, 99–112.

Chen, S. S.; Ji, H. X.; Chou, H.; Li, Q. Y.; Li, H. Y.; Suk, J. W.; Piner, R.; Liao, L.; Cai, W. W.; Ruoff, R. S. Millimeter-size single-crystal graphene by suppressing evaporative loss of Cu during low pressure chemical vapor deposition. Adv. Mater. 2013, 25, 2062–2065.

Rasool, H. I.; Song, E. B.; Mecklenburg, M.; Regan, B. C.; Wang, K. L.; Weiller, B. H.; Gimzewski, J. K. Atomic-scale characterization of graphene grown on copper (100) single crystals. J. Am. Chem. Soc. 2011, 133, 12536–12543.

Ogawa, Y.; Hu, B. S.; Orofeo, C. M.; Tsuji, M.; Ikeda, K.-I.; Mizuno, S.; Hibino, H.; Ago, H. Domain structure and boundary in single-layer graphene grown on Cu(111) and Cu(100) films. J. Phys. Chem. Lett. 2012, 3, 219–226.

Ma, T.; Ren, W. C.; Zhang, X. Y.; Liu, Z. B.; Gao, Y.; Yin, L.-C.; Ma, X.-L.; Ding, F.; Cheng, H.-M. Edge-controlled growth and kinetics of single-crystal graphene domains by chemical vapor deposition. Proc. Natl. Acad. Sci. USA 2013, 110, 20386–20391.

Girit, Ç. Ö.; Meyer, J. C.; Erni, R.; Rossell, M. D.; Kisielowski, C.; Yang, L.; Park, C.-H.; Crommie, M. F.; Cohen, M. L.; Louie, S. G. et al. Graphene at the edge: Stability and dynamics. Science 2009, 323, 1705–1708.

Yang, R.; Zhang, L. C.; Wang, Y.; Shi, Z. W.; Shi, D. X.; Gao, H. J.; Wang, E. G.; Zhang, G. Y. An anisotropic etching effect in the graphene basal plane. Adv. Mater. 2010, 22, 4014–4019.

Obraztsov, A. N.; Obraztsova, E. A.; Tyurnina, A. V.; Zolotukhin, A. A. Chemical vapor deposition of thin graphite films of nanometer thickness. Carbon 2007, 45, 2017–2021.

N'Diaye, A. T.; Van Gastel, R.; Martínez-Galera, A. J.; Coraux, J.; Hattab, H.; Wall, D.; Zu Heringdorf, F.-J. M.; Horn-von Hoegen, M.; Gómez-Rodríguez, J. M.; Poelsema, B. et al. In situ observation of stress relaxation in epitaxial graphene. New J. Phys. 2009, 11, 113056.

Nix, F. C.; MacNair, D. The thermal expansion of pure metals: Copper, gold, aluminum, nickel, and iron. Phys. Rev. 1941, 60, 597.

Chen, H.; Zhu, W. G.; Zhang, Z. Y. Contrasting behavior of carbon nucleation in the initial stages of graphene epitaxial growth on stepped metal surfaces. Phys. Rev. Lett. 2010, 104, 186101.

Yuan, Q. H.; Yakobson, B. I.; Ding, F. Edge-catalyst wetting and orientation control of graphene growth by chemical vapor deposition growth. J. Phys. Chem. Lett. 2014, 5, 3093–3099.

Mohsin, A.; Liu, L.; Liu, P. Z.; Deng, W.; Ivanov, I. N.; Li, G. L.; Dyck, O. E.; Duscher, G.; Dunlap, J. R.; Xiao, K. et al. Synthesis of millimeter-size hexagon-shaped graphene single crystals on resolidified copper. ACS Nano 2013, 7, 8924–8931.

Magnuson, C. W.; Kong, X. H.; Ji, H. X.; Tan, C.; Li, H. F.; Piner, R.; Ventrice, C. A.; Ruoff, R. S. Copper oxide as a “self-cleaning” substrate for graphene growth. J. Mater. Res. 2014, 29, 403–409.

Han, G. H.; Güneş, F.; Bae, J. J.; Kim, E. S.; Chae, S. J.; Shin, H.-J.; Choi, J.-Y.; Pribat, D.; Lee, Y. H. Influence of copper morphology in forming nucleation seeds for graphene growth. Nano Lett. 2011, 11, 4144–4148.

Kim, H.; Mattevi, C.; Calvo, M. R.; Oberg, J. C.; Artiglia, L.; Agnoli, S.; Hirjibehedin, C. F.; Chhowalla, M.; Saiz, E. Activation energy paths for graphene nucleation and growth on Cu. ACS Nano 2012, 6, 3614–3623.

Bhaviripudi, S.; Jia, X. T.; Dresselhaus, M. S.; Kong, J. Role of kinetic factors in chemical vapor deposition synthesis of uniform large area graphene using copper catalyst. Nano Lett. 2010, 10, 4128–4133.

Becker, O. M.; Ben-Shaul, A. Role and mechanism of island formation in chemisorption. Phys. Rev. Lett. 1988, 61, 2859–2862.

Li, X. S.; Magnuson, C. W.; Venugopal, A.; An, J.; Suk, J. W.; Han, B. Y.; Borysiak, M.; Cai, W. W.; Velamakanni, A.; Zhu, Y. W. et al. Graphene films with large domain size by a two-step chemical vapor deposition process. Nano Lett. 2010, 10, 4328–4334.

Ni, Z. H.; Wang, Y. Y.; Yu, T.; Shen, Z. X. Raman spectroscopy and imaging of graphene. Nano Res. 2008, 1, 273–291.

Sun, J. Y.; Chen, Y. B.; Priydarshi, M. K.; Chen, Z.; Bachmatiuk, A.; Zou, Z. Y.; Chen, Z. L.; Song, X. J.; Gao, Y. F.; Rümmeli, M. H. et al. Direct chemical vapor deposition-derived graphene glasses targeting wide ranged applications. Nano Lett. 2015, 15, 5846–5854.

Chen, Y. B.; Sun, J. Y.; Gao, J. F.; Du, F.; Han, Q.; Nie, Y. F.; Chen, Z. L.; Bachmatiuk, A.; Priydarshi, M. K.; Ma, D. L. et al. Growing uniform graphene disks and films on molten glass for heating devices and cell culture. Adv. Mater. 2015, 27, 7839–7846.

Acknowledgements

We acknowledge financial support from the National Natural Science Foundation of China (Nos. 21173004, 51520105003, 51432002, 21222303 and 51362029) and the National Basic Research Program of China (Nos. 2014CB932500, 2013CB932603, 2012CB933404, 2011CB933003, and 2011CB921904), the National Program for Support of Top-Notch Young Professionals, and Beijing Municipal Science & Technology Commission (No. Z161100002116002).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Ren, H., Wang, H., Lin, L. et al. Rapid growth of angle-confined large-domain graphene bicrystals. Nano Res. 10, 1189–1199 (2017). https://doi.org/10.1007/s12274-017-1534-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-017-1534-2