Abstract

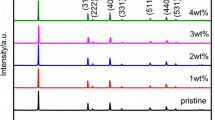

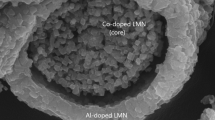

Spinel phase LiMn2O4 was successfully embedded into monoclinic phase layeredstructured Li2MnO3 nanorods, and these spinel-layered integrate structured nanorods showed both high capacities and superior high-rate capabilities as cathode material for lithium-ion batteries (LIBs). Pristine Li2MnO3 nanorods were synthesized by a simple rheological phase method using α-MnO2 nanowires as precursors. The spinel-layered integrate structured nanorods were fabricated by a facile partial reduction reaction using stearic acid as the reductant. Both structural characterizations and electrochemical properties of the integrate structured nanorods verified that LiMn2O4 nanodomains were embedded inside the pristine Li2MnO3 nanorods. When used as cathode materials for LIBs, the spinel-layered integrate structured Li2MnO3 nanorods (SL-Li2MnO3) showed much better performances than the pristine layered-structured Li2MnO3 nanorods (L-Li2MnO3). When charge–discharged at 20 mA·g−1 in a voltage window of 2.0–4.8 V, the SL-Li2MnO3 showed discharge capacities of 272.3 and 228.4 mAh·g−1 in the first and the 60th cycles, respectively, with capacity retention of 83.8%. The SL-Li2MnO3 also showed superior high-rate performances. When cycled at rates of 1 C, 2 C, 5 C, and 10 C (1 C = 200 mA·g−1) for hundreds of cycles, the discharge capacities of the SL-Li2MnO3 reached 218.9, 200.5, 147.1, and 123.9 mAh·g−1, respectively. The superior performances of the SL-Li2MnO3 are ascribed to the spinel-layered integrated structures. With large capacities and superior high-rate performances, these spinel-layered integrate structured materials are good candidates for cathodes of next-generation high-power LIBs.

Similar content being viewed by others

References

Whittingham, M. S. Lithium batteries and cathode materials. Chem. Rev. 2004, 104, 4271–4301.

Armstrong, M. J.; O’Dwyer, C.; Macklin, W. J.; Holmes, J. D. Evaluating the performance of nanostructured materials as lithium-ion battery electrodes. Nano Res. 2014, 7, 1–62.

Yang, Z. G.; Zhang, J. L.; Kintner-Meyer, M. C. W.; Lu, X. C.; Choi, D.; Lemmon, J. P. L.; Liu, J. Electrochemical energy storage for green grid. Chem. Rev. 2011, 111, 3577–3613.

Yu, H. J.; Zhou, H. S. High-energy cathode materials (Li2MnO3–LiMO2) for lithium-ion batteries. J. Phys. Chem. Lett. 2013, 4, 1268–1280.

Ye, D. L.; Wang, L. Z. Li2MnO3 based Li-rich cathode materials: Towards a better tomorrow of high energy lithium ion batteries. Mater. Technol. 2014, 29, A59–A69.

Johnson, C. S.; Kim, J. S.; Lefief, C.; Li, N.; Vaughey, J. T.; Thackeray, M. M. The significance of the Li2MnO3 component in ‘composite’ xLi2MnO3·(1-x) LiMn0.5Ni0.5O2 electrodes. Electrochem. Commun. 2004, 6, 1085–1091.

Thackeray, M. M.; Kang, S. H.; Johnson, C. S.; Vaughey, J. T.; Hackney, S. A. Comments on the structural complexity of lithium-rich Li1+x M1-x O2 electrodes (M = Mn, Ni, Co) for lithium batteries. Electrochem. Commun. 2006, 8, 1531–1538.

Jarvis, K. A.; Deng, Z. Q.; Allard, L. F.; Manthiram, A.; Ferreira, P. J. Atomic structure of a lithium-rich layered oxide material for lithium-ion batteries: Evidence of a solid solution. Chem. Mater. 2011, 23, 3614–3621.

Robertson, A. D.; Bruce, P. G. Mechanism of electrochemical activity in Li2MnO3. Chem. Mater. 2003, 15, 1984–1992.

Armstrong, A. R.; Holzapfel, M.; Novák, P.; Johnson, C. S.; Kang, S. H.; Thackeray, M. M.; Bruce, P. G. Demonstrating oxygen loss and associated structural reorganization in the lithium battery cathode Li[Ni0.2Li0.2Mn0.6]O2. J. Am. Chem. Soc. 2006, 128, 8694–8698.

Yan, P. F.; Xiao, L.; Zheng, J. M.; Zhou, Y. G.; He, Y.; Zu, X. T.; Mao, S. X.; Xiao, J.; Gao, F.; Zhang, J. G. et al. Probing the degradation mechanism of Li2MnO3 cathode for Li-ion batteries. Chem. Mater. 2015, 27, 975–982.

Yu, C.; Wang, H.; Guan, X. F.; Zheng, J.; Li, L. P. Conductivity and electrochemical performance of cathode xLi2MnO3·(1-x)LiMn1/3Ni1/3Co1/3O2 (x = 0.1, 0.2, 0.3, 0.4) at different temperatures. J. Alloys Compd. 2013, 546, 239–245.

Lim, J.; Moon, J.; Gim, J.; Kim, S.; Kim, K.; Song, J. J.; Kang, J.; Im, W. B.; Kim, J. Fully activated Li2MnO3 nanoparticles by oxidation reaction. J. Mater. Chem. 2012, 22, 11772–11777.

Kubota, K.; Kaneko, T.; Hirayama, M.; Yonemura, M.; Imanari, Y.; Nakane, K.; Kanno, R. Direct synthesis of oxygen-deficient Li2MnO3-x for high capacity lithium battery electrodes. J. Power Sources 2012, 216, 249–255.

Xiao, L.; Xiao, J.; Yu, X. Q.; Yan, P. F.; Zheng, J. M.; Engelhard, M.; Bhattacharya, P.; Wang, C. M.; Yang, X.-Q.; Zhang, J. G. Effects of structural defects on the electrochemical activation of Li2MnO3. Nano Energy 2015, 16, 143–151.

Dong, X.; Xu, Y. L.; Xiong, L. L.; Sun, X. F.; Zhang, Z. W. Sodium substitution for partial lithium to significantly enhance the cycling stability of Li2MnO3 cathode material. J. Power Sources 2013, 243, 78–87.

Dong, X.; Xu, Y. L.; Yan, S.; Mao, S. C.; Xiong, L. L.; Sun, X. F. Towards low-cost, high energy density Li2MnO3 cathode materials. J. Mater. Chem. A 2015, 3, 670–679.

Gao, Y. R.; Wang, X. F.; Ma, J.; Wang, Z. X.; Chen, L. Q. Selecting substituent elements for Li-rich Mn-based cathode materials by density functional theory (DFT) calculations. Chem. Mater. 2015, 27, 3456–3461.

Ma, J.; Zhou, Y. N.; Gao, Y. R.; Kong, Q. Y.; Wang, Z. X.; Yang, X. Q.; Chen, L. Q. Molybdenum substitution for improving the charge compensation and activity of Li2MnO3. Chem.—Eur. J. 2014, 20, 8723–8730.

Lee, E. S.; Huq, A.; Chang, H. Y.; Manthiram, A. Highvoltage, high-energy layered-spinel composite cathodes with superior cycle life for lithium-ion batteries. Chem. Mater. 2012, 24, 600–612.

Kim, D.; Sandi, G.; Croy, J. R.; Gallagher, K. G.; Kang, S. H.; Lee, E.; Slater, M. D.; Johnson, C. S.; Thackeray, M. M. Composite ‘layered-layered-spinel’ cathode structures for lithium-ion batteries. J. Electrochem. Soc. 2013, 160, A31–A38.

Feng, X.; Yang, Z. Z.; Tang, D. C.; Kong, Q. Y.; Gu, L.; Wang, Z. X.; Chen, L. Q. Performance improvement of Li-rich layer-structured Li1.2Mn0.54Ni0.13Co0.13O2 by integration with spinel LiNi0.5Mn1.5O4. Phys. Chem. Chem. Phys. 2015, 17, 1257–1264.

Zhao, J. Q.; Ellis, S.; Xie, Z. Q.; Wang, Y. Synthesis of integrated layered-spinel composite cathode materials for highvoltage lithium-ion batteries up to 5.0 V. ChemElectroChem 2015, 2, 1821–1829.

Wang, M.; Xue, Y. H.; Zhang, K. L.; Zhang, Y. X. Synthesis of FePO4·2H2O nanoplates and their usage for fabricating superior high-rate performance LiFePO4. Electrochim. Acta 2011, 56, 4294–4298.

Ranjusha, R.; Nair, A. S.; Ramakrishna, S.; Anjali, P.; Sujith, K.; Subramanian, K. R. V.; Sivakumar, N.; Kim, T. N.; Nair, S. V.; Balakrishnan, A. Ultra-fine MnO2 nanowire based high performance thin film rechargeable electrodes: Effect of surface morphology, electrolytes and concentrations. J. Mater. Chem. 2012, 22, 20465–20471.

Li, Q. G.; Olson, J. B.; Penner, R. M. Nanocrystalline a-MnO2 nanowires by electrochemical step-edge decoration. Chem. Mater. 2004, 16, 3402–3405.

Lu, Z. H.; Beaulieu, L. Y.; Donaberger, R. A.; Thomas, C. L.; Dahn, J. R. Synthesis, structure, and electrochemical behavior of Li[NixLi1/3–2x/3Mn2/3–x/3]O2. J. Electrochem. Soc. 2002, 149, A778–A791.

Lu, J.; Chang, Y. L.; Song, B. H.; Xia, H.; Yang, J. R.; Lee, K. S.; Lu, L. High energy spinel-structured cathode stabilized by layered materials for advanced lithium-ion batteries. J. Power Sources 2014, 271, 604–613.

Julien, C. M.; Massot, M. Lattice vibrations of materials for lithium rechargeable batteries III. Lithium manganese oxides. Mater. Sci. Eng. B 2003, 100, 69–78.

Julien, C. M.; Massot, M. Raman spectroscopic studies of lithium manganates with spinel structure. J. Phys.: Condens. Matter 2003, 15, 3151.

Ramana, C. V.; Massot, M.; Julien, C. M. XPS and Raman spectroscopic characterization of LiMn2O4 spinels. Surf. Interface Anal. 2005, 37, 412–416.

Nesbitt, H. W.; Banerjee, D. Interpretation of XPS Mn(2p) spectra of Mn oxyhydroxides and constraints on the mechanism of MnO2 precipitation. Am. Mineral. 1998, 83, 305–315.

Thackeray, M. M.; David, W. I. F.; Bruce, P. G.; Goodenough, J. B. Lithium insertion into manganese spinels. Mater. Res. Bull. 1983, 18, 461–472.

Ohzuku, T.; Kitagawa, M.; Hirai, T. Electrochemistry of manganese dioxide in lithium nonaqueous cell III. X-ray diffractional study on the reduction of spinel-related manganese dioxide. J. Electrochem. Soc. 1990, 137, 769–775.

Hosono, E.; Kudo, T.; Honma, I.; Matsuda, H.; Zhou, H. S. Synthesis of single crystalline spinel LiMn2O4 for a lithium ion battery with high power density. Nano Lett. 2009, 9, 1045–1051.

Johnson, C. S.; Li, N.; Vaughey, J. T.; Hackney, S. A.; Thackeray, M. M. Lithium–manganese oxide electrodes with layered-spinel composite structures xLi2MnOI3·(1-x)Li1+y Mn2-y O4 (0-x-1, 0=y=0.33) for lithium batteries. Electrochem. Commun. 2005, 7, 528–536.

Park, S. H.; Kang, S. H.; Johnson, C. S.; Amine, K.; Thackeray, M. M. Lithium-manganese–nickel-oxide electrodes with integrated layered-spinel structures for lithium batteries. Electrochem. Commun. 2007, 9, 262–268.

Xiao, X. L.; Lu, J.; Li, Y. D. LiMn2O4 microspheres: Synthesis, characterization and use as cathode in lithium ion batteries. Nano Res. 2010, 3, 733–737.

Li, Z.; Du, F.; Bie, X. F.; Zhang, D.; Cai, Y. M.; Cui, X. R.; Wang, C. Z.; Chen, G.; Wei, Y. J. Electrochemical kinetics of the Li[Li0.23Co0.3Mn0.47]O2 cathode material studied by GITT and EIS. J. Phys. Chem. C 2010, 114, 22751–22757.

Yu, H. J.; Wang, Y. R.; Asakura, D.; Hosono, E.; Zhang, T.; Zhou, H. S. Electrochemical kinetics of the 0.5Li2MnO3· 0.5LiMn0.42Ni0.42Co0.16O2 ‘composite’ layered cathode material for lithium-ion batteries. RSC Adv. 2012, 2, 8797–8807.

Park, M.; Zhang, X. C.; Chung, M.; Less, G. B.; Sastry, A. M. A review of conduction phenomena in Li-ion batteries. J. Power Sources 2010, 195, 7904–7929.

Zhuang, Q. C.; Wei, T.; Du, L. L.; Cui, Y. L.; Fang, L.; Sun, S. G. An electrochemical impedance spectroscopic study of the electronic and ionic transport properties of spinel LiMn2O4. J. Phys. Chem. C 2010, 114, 8614–8621.

Kunduraci, M.; Al-Sharab, J. F.; Amatucci, G. G. Highpower nanostructured LiMn2–x NixO4 high-voltage lithium-ion battery electrode materials: Electrochemical impact of electronic conductivity and morphology. Chem. Mater. 2006, 18, 3585–3592.

Yang, J. G.; Han, X. P.; Zhang, X. L.; Cheng, F. Y.; Chen, J. Spinel LiNi0.5Mn1.5O4 cathode for rechargeable lithiumion batteries: Nano vs micro, ordered phase (P4332) vs disordered phase (Fd3 _ m). Nano Res. 2013, 6, 679–687.

Bard, A. J.; Faulkner, L. R. Electrochemical Methods: Fundamentals and Applications; Wiley: New York, 1980.

Acknowledgements

The authors thank the Center for Electron Microscopy at Wuhan University for help in taking the TEM and high-resolution TEM images for the materials. This study was supported by the National Natural Science Foundation of China (No. 21271145), the National Science Foundation of Hubei Province (No. 2015CFB537) and the Funds for Creative Research Groups of Hubei Province (No. 2014CFA007).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

12274_2016_1314_MOESM1_ESM.pdf

Spinel-layered integrate structured nanorods with both high capacity and superior high-rate capability as cathode material for lithium-ion batteries

Rights and permissions

About this article

Cite this article

He, H., Cong, H., Sun, Y. et al. Spinel-layered integrate structured nanorods with both high capacity and superior high-rate capability as cathode material for lithium-ion batteries. Nano Res. 10, 556–569 (2017). https://doi.org/10.1007/s12274-016-1314-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-016-1314-4