Abstract

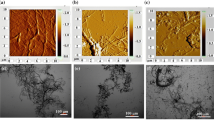

In the present study, nanofibrils of cellulose are extracted from waste jute fibers using high energy planetary ball milling process in wet condition. The rate of refinement of untreated fibers having non-cellulosic contents was found slower than treated fibers due to strong holding of fiber bundles by non-cellulosic contents. At the end of three hours of wet milling, untreated fibers were refined to the size of 850 nm and treated fibers were refined to the size of 443 nm. In the subsequent stage, composite films of poly lactic acid (PLA) were prepared by solvent casting with 3 wt% loading of untreated jute nanofibrils, treated jute nanofibrils and microcrystalline cellulose. The influence of non-cellulosic contents on mechanical properties of PLA films are investigated based on results of tensile test, dynamic mechanical analysis and differential scanning calorimetry. The maximum improvement was observed in case of treated jute nanofibril/PLA composite film where initial modulus and tensile strength increased by 207.69 % and 168.67 %, respectively as compared to neat PLA film. These improvements are attributed to the increased interaction of treated jute nanofibrils with PLA matrix due to their higher precentage of cellulosic contents and mechanically activated surface.

Similar content being viewed by others

References

D. Klemm, D. Schumann, F. Kramer, N. Hebler, M. Hornung, H. Schmauder, and S. Marsch, Adv. Polym. Sci., 205, 49 (2006).

T. Zimmermann, N. Bordeanu, and E. Strub, Carbohyd. Polym., 79, 1086 (2010).

A. J. Svagan, M. A. Samir, and L. A. Berglund, Adv. Mater., 20, 1263 (2008).

M. Nogi, S. Iwamoto, A. N. Nakagaito, and H. Yano, Adv. Mater., 21, 1595 (2009).

H. Fukuzumi, T. Saito, Y. Kumamoto, and A. Isogai, Biomacromolecules, 10, 1584 (2009).

H. Wang, L. Huang, and L. Yafei, Fiber. Polym., 10, 442 (2009).

V. Baheti, V. V. T. Padil, J. Militky, M. Cernik, and R. Mishra, J. Fiber Bioeng. Informat., 6, 175 (2013).

M. F. Rosa, E. S. Medeiros, J. A. Malmonge, K. S. Gregorski, D. F. Wood, L. H. C. Mattoso, G. Glenn, W. J. Orts, and S. H. Imam, Carbohyd. Polym., 81, 83 (2010).

D. Pasquini, E. D. M. Teixeira, A. A. D. S. Curvelo, M. N. Belgacem, and A. Dufresne, Ind. Crop Prod., 32, 486 (2010).

R. Zuluaga, J. L. Putaux, J. Cruz, J. Velez, I. Mondragon, and P. Ganan, Carbohyd. Polym., 76, 51 (2009).

R. Li, J. Fei, Y. Cai, Y. Li, J. Feng, and J. Yao, Carbohyd. Polym., 76, 94 (2009).

B. Wang and M. Sain, Compos. Sci. Technol., 67, 2521 (2007).

A. Alemdar and M. Sain, Bioresource Technology, 99, 1664 (2008).

N. Reddy and Y. Yang, Polymer, 46, 5494 (2005).

D. Plackett, T. L. Andersen, W. B. Pedersen, and L. Nielsen, Compos. Sci. Technol., 63, 1287 (2003).

J. Gassan and A. K. Bledzki, J. Appl. Polym. Sci., 71, 623 (1999).

T. Yu, J. Ren, S. Li, H. Yuan, and Y. Li, Compos. Part A-Appl. S., 41, 499 (2010).

D. Ray, B. K. Sarkar, R. K. Basak, and A. K. Rana, J. Appl. Polym. Sci., 94, 123 (2004).

M. S. Islam, K. L. Pickering, and N. J. Foreman, Compos. Part A-Appl. S., 41, 596 (2010).

T. H. Nam, S. Ogihara, N. H. Tung, and S. Kobayashi, Compos. Part B-Eng., 42, 164 (2011).

V. Baheti and J. Militky, Fiber. Polym., 14, 133 (2013).

V. Baheti, R. Abbasi, J. Militky, and J. Dobias, Vlakna a Textil, 19, 10 (2012).

V. Baheti, J. Militky, and M. Marsalkova, Polym. Compos., 34, 2133 (2013).

H. Liu, L. You, H. Jin, and W. Yu, Fiber. Polym., 14, 389 (2013).

H. Choi and J. Lee, Fiber. Polym., 13, 217 (2012).

M. Akerholm, B. Hinterstoisser, and L. Salmén, Carbohyd. Res., 339, 569 (2004).

R. Tokoro, D. M. Vu, K. Okubo, T. Tanaka, T. Fujii, and T. Fujiura, J. Mater. Sci., 43, 775 (2008).

L. Petersson and K. Oksman, Compos. Sci. Technol., 66, 2187 (2006).

S. Cho, H. Park, Y. Yun, and H. Jin, Fiber. Polym., 14, 1001 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baheti, V., Mishra, R., Militky, J. et al. Influence of noncellulosic contents on nano scale refinement of waste jute fibers for reinforcement in polylactic acid films. Fibers Polym 15, 1500–1506 (2014). https://doi.org/10.1007/s12221-014-1500-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-014-1500-5