Abstract

Carbon dioxide (CO2) reduction into chemicals or fuels by electrocatalysis can effectively reduce greenhouse gas emissions and alleviate the energy crisis. Currently, CO2 electrocatalytic reduction (CO2RR) has been considered as an ideal way to achieve “carbon neutrality.” In CO2RR, the characteristics and properties of catalysts directly determine the reaction activity and selectivity of the catalytic process. Much attention has been paid to carbon-based catalysts because of their diversity, low cost, high availability, and high throughput. However, electrically neutral carbon atoms have no catalytic activity. Incorporating heteroatoms has become an effective strategy to control the catalytic activity of carbon-based materials. The doped carbon-based catalysts reported at present show excellent catalytic performance and application potential in CO2RR. Based on the type and quantity of heteroatoms doped into carbon-based catalysts, this review summarizes the performances and catalytic mechanisms of carbon-based materials doped with a single atom (including metal and without metal) and multi atoms (including metal and without metal) in CO2RR and reveals prospects for developing CO2 electroreduction in the future.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The global demand for energy is rapidly increasing due to economic development. Currently, ∼75% of human energy consumption still depends on fossil fuels represented by coal [1]. The carbon dioxide (CO2) released from fossil fuel combustion cannot be transformed by plants in time, and the atmospheric CO2 concentration is increasing year by year, causing serious global warming [1, 2]. It was revealed that the atmospheric CO2 concentration exceeded the safety limit valve (415.2 ppm vs. 350 ppm [3]) in 2019, and Earth’s surface temperature has risen 1.2 °C in the past 100 years [4], which will undoubtedly greatly affect the harmonious development of human society. How to reduce the atmospheric CO2 concentration and realize the sustainable development of society has become an important challenge.

In 2015, the United Nations proposed goals to achieve “carbon neutrality” and “emission peak” by a certain period of time. On the one hand, it is necessary to find renewable clean energy (such as wind energy, solar energy, etc.) to replace fossil fuels and reduce CO2 emissions from the source. On the other hand, technical approaches should be adopted to reduce the atmospheric CO2 concentration, such as CO2 storage [5] and CO2 conversion [6]. CO2 can be converted into high-value-added carbon chemicals, such as methane, methanol, formic acid, and syngas, through technical means [7,8,9,10,11], which seems to be more efficient than CO2 storage. CO2 is a rich and cheap C1 resource. In nature, CO2 can be reduced by plants using photosynthesis to realize the carbon cycle. Inspired by this, how to use chemical means to convert CO2 into high-value-added chemicals has attracted great attention from scientists.

CO2 conversion technologies mainly include chemical conversion [12], photochemical conversion [13,14,15], and electrochemical conversion [16,17,18,19]. Photochemical and electrochemical conversions use energy conversion devices to realize the carbon cycle by inputting clean energy light or electricity. This has been of wide interest because of the characteristics of simple operation, small floor area, and environmentally friendliness. This process can not only greatly reduce the CO2 content in the air but also store clean energy, such as solar energy and wind energy, in the form of chemical energy, which can effectively and perfectly achieve the carbon cycle, as shown in Fig. 1. Compared with CO2 photocatalytic reduction, the electrocatalytic reduction of CO2 (CO2RR) can control the target product synthesized by adjusting the applied potential, which is flexible and easy to adjust [20,21,22] while avoiding catalyst deactivation caused by electron-hole recombination [18, 23]. Thus, developing CO2RR technologies has high research significance and commercial value for the carbon cycle and energy storage.

Working Principle of CO2RR

CO2RR requires an electrocatalytic device (Fig. 2) that is composed of a cathode, an anode, and an electrolyte, including a working electrode (WE), reference electrode (RE), and counter electrode (CE). The electroreduction of CO2 takes place at the WE. The oxygen precipitation reaction occurs at the CE at the positive stage, that is, 2H2O → O2 + 4H+ + 4e−. The WE, which is made of a catalyst, is the object of the CO2RR study. Its intrinsic properties will directly determine the catalytic activity and conversion efficiency of electrocatalytic CO2.

CO2RR occurs in four processes [24]: (1) CO2 adsorption, (2) CO2 activation, (3) product formation, and (4) product separation and diffusion. CO2 is very thermodynamically stable because of its strong C = O bond energy (bond energy 750 kJ/mol), which is much larger than those of C − H, C − O, and C − C bonds [25, 26]. CO2 conversion must first overcome the huge energy barrier of the C = O bond, which can be realized by a single electron attacking CO2 molecules to form \({^{ * } {\text{CO}}_{2}^{{ \cdot - }} }\) free radical anions \(\left( {{\text{CO}}_{2} \left( g \right) + e^{ - } \to ^{ * } {\text{CO}}_{2}^{{ \cdot - }} } \right)\) (standard reduction potential − 1.9 V [3]). The products of CO2RR vary according to the number of transferred electrons and can be classified into three types based on the number of carbon atoms, namely, C1 chemicals, such as CO [27, 28], CH4 [29, 30], HCOOH [31, 32], and CH3OH [33]; C2 chemicals such as CH2CH2 [34], CH3CH2OH [35], and CH3COOH [32]; and C3 chemicals, such as propanol [36], and acetone [37]. Table 1 lists the electroreduction reactions on the WE and the corresponding standard reduction potentials. The hydrogen evolution reaction has a very similar standard reduction potential to electrocatalytic CO2 to radical anions in aqueous electrolytes, so they are competitive reactions. The final product depends on the inherent properties of the catalyst [3]. Since the formation of C2 and C3 chemicals requires more electron transfer and higher overpotential, reducing CO2 to C1 chemicals is easier than reducing to C2 and C3 chemicals. At low applied voltage, the C≡O bonds in the intermediate *CO cannot be struck, and CO is the main reduction product. At higher applied voltage, the output electrons gain enough energy to attack *CO, and the reduction products of multielectron transfer such as CH3OH, C2H4, and C2H5OH can be obtained.

Catalysts commonly used for CO2RR include metal [38], nonmetal [39, 40], and molecular catalysts. Metal catalysts (including pure metals, metal oxides, etc.) have high catalytic activities and rich products but are expensive and difficult to recover. Nonmetallic catalysts, especially carbon-based catalysts, are ideal substitutes for noble-metal catalysts. Molecular catalysts have high activities but have extremely complex preparation procedures. Hence, carbon-based catalysts show excellent application prospects in CO2RR [41,42,43].

Carbon-Based Catalysts

Carbon-based materials have attracted much attention due to their diversity, low cost, high conductivity, and high throughput [44]. Nowadays, carbon-based materials have been widely used in energy storage, catalysis, and other fields [45, 46] and are also used as effective catalysts for CO2RR [47,48,49,50,51]. Carbon-based materials in aqueous solution have chemical inertness under negative potential, which can inhibit H2 release and improve CO2 reduction activity. Hence, carbon-based materials are promising CO2 electroreduction catalysts.

Electrically neutral carbon atoms have no catalytic active sites, but their catalytic performance can be improved by heteroatom doping, through which reaction sites for adsorption and activation of CO2 can be created, thus effectively regulating the catalytic activity. There are many types of heteroatoms, including N [52,53,54,55], B [56], F [57], and multi atoms [58,59,60], that can be doped into carbon-based materials. More and more carbon-based catalysts have recently been developed and used for CO2RR.

Synthesis Methods of Doped Carbon Materials

Methods for preparing doped carbon materials are post-treatment synthesis and in situ synthesis. Post-treatment synthesis methods are post-treatment modifications of traditional carbon materials using heteroatom-containing precursors that aim to introduce heteroatoms into carbon materials. For example, the commonly used N-containing precursors are ammonia, ethylenediamine, hexamethylene tetramine, and urea. Most of the heteroatoms introduced by post-treatment synthesis exist on the surface of the carbon materials, and a few of them can enter the carbon skeleton, hence a not high heteroatom content in carbon materials. Their disadvantages include cumbersome procedures and high costs.

In situ synthesis methods introduce heteroatoms directly into carbon materials using high-heteroatom-content precursors. Taking N-doping as an example, common precursors are mainly melamine, benzylamine, acetonitrile, aniline, and N-containing heterocyclic compounds. The commonly used in situ synthesis methods mainly include templating, chemical vapor deposition, hydrothermal synthesis, sol–gel, and high-temperature pyrolysis. These methods can introduce the heteroatom-containing functional groups uniformly into the carbon structure. However, at present, most in situ synthesis methods are still in the experimental stage, and some problems abound. (1) The in situ synthesis system is limited, and sometimes, the required tissue cannot be formed by reaction. (2) The density of the obtained product is not high. (3) The reaction process is not easily controllable, and the formation of the mesophase has an adverse impact on the properties of materials.

Parameters for Evaluating Catalyst Performance

-

(1)

Onset potential/overpotential

The resistance of CO2RR makes the initial potential smaller than its thermodynamic equilibrium potential. Overpotential η is the difference between these two potentials. In CO2RR, the role of the catalyst is to reduce the reaction activation energy and overpotential. The overpotential directly reflects the performance of the catalyst.

-

(2)

Current density and partial current density

Current density reflects the speed of electron transfer and thus the speed of electrocatalytic reaction. Current density can be divided into total current density and partial current density. Total current density is calculated as the ratio of the current value measured by the electrochemical workstation to the geometric area of the working electrode, J, mA/cm2. Partial current density is the current density contributed by each product, which is calculated by multiplying the total current density and Faradaic efficiency (FE) of each product. The partial current density reflects the selectivity of some products to some extent.

-

(3)

FE

FE measures the efficiency with which the electrons are transferred for a reaction. FE is a direct indicator for evaluating the catalytic selectivity of catalysts.

-

(4)

Energy efficiency (EE)

EE = [Eredox/(Eredox + η)] × FE, where Eredox refers to the thermodynamic redox potential.

-

(5)

Tafel slope

The Tafel slope is the slope of the approximately straight-line segment on the semilogarithmic curve obtained when plotting the overpotential and the logarithm of partial current density. It indicates the degree to which the electrode potential needs to be changed to achieve a certain current.

Research Progress on CO2 Electrocatalysts

Carbon atoms in carbon-based materials can be assembled into various sizes and structures with different advantages, such as zero-dimensional (carbon quantum dots), one-dimensional (carbon nanotubes (CNTs), carbon nanofibers), two-dimensional (graphene, carbon nanosheets), and three-dimensional (porous carbon spheres) carbon nanomaterials. Electrically neutral carbon atoms have limited adsorption capacity for CO2. Doping can make carbon atoms electronegative, thus inducing charge redistribution and creating reaction sites for CO2 adsorption and activation. The selectivity and activity of carbon-based materials for CO2RR are different due to different hybrid states or nanostructures of the carbon atom. In addition, the selectivity and activity of heteroatom-doped carbon materials for CO2 are different. In Fig. 3, based on the type and number of doped atoms, different from the previous classification method, this review discusses the single-atom-doped (including metal and without metal) and multiatom-doped (including metal and without metal) carbon-based catalysts. Through this classified discussion, on the one hand, we can easily grasp the effect of heteroatom doping on the improvement of the catalytic activity of carbon-based materials. On the other hand, it may be helpful for researchers to explore new ways to improve the catalytic activities of carbon-based materials. Table 2 lists some representative carbon-based catalysts and their performances in CO2RR.

Monatomic Doping

Studies have been published on heteroatom doping in carbon materials, including N, B, S, F, and metal atoms. Atom doping improves the electronegativity of carbon materials and creates active sites for CO2RR.

Nonmetallic Monatomic Doping

N doping N and C atoms have similar radii but different electronegativities. The incorporation of N into carbon-based materials has shown excellent conductivity and more active sites. Hence, N atoms are very important doping atoms in carbon-based materials.

Carbon quantum dots (CQDs) are a class of zero-dimensional carbon nanomaterials with significant fluorescence properties and many advantages such as low cost, environmental friendliness, and good electrochemical performance. They have a good application prospect in the field of catalyst preparation. N-doped CQDs have been prepared and used for CO2RR. Wu et al. [35] synthesized nanosized N-doped graphene quantum dots (NGQDs) with a sawtooth profile and used them to electrocatalytically reduce CO2 to hydrocarbons. The products included CH4, C2H4, and oxygenates, with a maximum FE of 90% and selectivity for C2 + C3 products exceeding 55% (Fig. 4a). The results showed similar catalytic efficiency and product distribution of NGQDs to copper-based nanoparticles. NGQDs showed high activity and selectivity in promoting the reduction of CO2 to CO.

Reproduced with permission from Ref. [35]. Copyright © 2016 Nature Publishing Group. b Performance of functionalized GQD for electrochemical reduction of CO2. Reproduced with permission from Ref. [61]. Copyright © 2021 Nature Publishing Group

a Performance of NGQDs in electro catalytic reduction of CO2.

Heteroatom doping can induce charge redistribution and activate reaction sites. The different properties of functional groups will also have different results for the charge redistribution of carbon atoms, which will affect the electrocatalytic activity. In 2021, Zhang et al. [61] functionalized GQDs through functional groups (–OH or –NH2), which were used for CO2 to CH4 conversion, and found that electron-donating groups can promote the electroreduction of CO2 to CH4 while electron-withdrawing groups can inhibit CO2 electroreduction. For the electron-donating group, the yield of CH4 was positively correlated with the electron-donating ability and quantity. At room temperature, the FE of CH4 can reach 70.0%, and the partial current density can reach − 200 mA/cm2. In Fig. 4b, GQDs showed high selectivity and high yield.

Carbon nanofibers are one-dimensional carbon nanomaterials with high strength, good thermal conductivity, and high conductivity. N-doped carbon nanomaterials have been prepared. Kumar et al. [52] carbonized polyaniline into carbon nanofibers as a catalyst for the electrocatalytic reduction of CO2 to CO (Fig. 5a). The current density of the catalyst is more than 13 times that of silver. It is found that the high electronegativity of N and the high positive charge on the carbon atom result in the strong catalytic activity of the catalyst. The structure of the nanofibers and a single fiber can form fractal wavy active centers, which improves the catalytic activity.

Reproduced with permission from Ref. [52]. Copyright © 2016 Wiley. b Electrocatalytic properties of NCNTs for CO2. Reproduced with permission from Ref. [62]. Copyright © 2015 Wiley. c Electrocatalytic properties of N-doped carbon nanotubes for CO2. Reproduced with permission from Ref. [63]. Copyright © 2015 ACS. d Electrocatalytic properties of N-doped carbon nanotubes. Reproduced with permission from Ref. [64] for CO2. Copyright © 2021 Wiley

a Schematic diagram of CO2 reduction mechanism.

CNTs are also classic one-dimensional carbon nanomaterials with high conductivity and are widely used in electrochemistry and hydrogen storage. N-doped CNTs (NCNTs) have also been prepared. Sharma et al. [62] used acetonitrile as the N source to synthesize NCNTs with a great N content at 850 °C for the electrocatalytic reduction of CO2 to CO, with FE as high as 80%. They also found that the change in pyridine N content in NCNTs leads to a change in FE (Fig. 5b). This also confirms that pyridine N is the main active site in the electrocatalytic reduction of CO2 to CO.

Dicyandiamide can also be doped into carbon materials as an N source. Wu et al. [63] prepared NCNTs with dicyandiamide as the N source. The catalyst can efficiently and stably reduce CO2 to CO at an overpotential of − 0.18 V (vs. RHE) and selectivity of 80% (Fig. 5c). N doping in CNTs improves the conductivity of the catalyst, increases the catalytic active sites, promotes CO2 activation, and reduces hydrogen evolution. Density functional theory (DFT) calculations show that pyridine nitrogen is the highest selective site for CO generation. The catalyst electrode showed strong stability after continuous operation for 10 h.

Recently, Shi et al. [64] have prepared NCNTs with polyaniline as the main N source and used them for the electrocatalytic reduction of CO2 to CO. At an overpotential of − 0.83 V (vs. RHE), the partial current density of CO can reach 13.8 mA/cm2. At an overpotential of − 0.63 V (vs. RHE), the FE reaches a maximum value of 93%. In Fig. 5d, the catalyst shows high selectivity and high efficiency. For CO2 in simulated flue gas (15% CO2, 77% N2, and 8% O2), the catalyst can directly reduce CO2 to CO, with FE as high as 70%. The catalyst shows an extremely high activity, which may be mainly due to the rich imine N in the catalyst [65].

Carbon nanosheets are two-dimensional carbon nanomaterials with good electrochemical properties. Li et al. [66] used the post-etching strategy to prepare wrinkled N-doped porous carbon nanosheets (WNCS) for CO2RR. The initial overpotential of the catalyst is as low as − 0.19 V (vs. RHE). When the overpotential is − 0.49 V (vs. RHE), the FE is 84%. The two-dimensional nanoporous structure of the WNCS promotes the rapid charge transfer and is conducive to the rapid adsorption of CO2 to the pyridine N active center. DFT results show that pyridine N can provide a favorable binding site for intermediate ∗ COOH and promote catalytic reduction.

Graphene is a two-dimensional carbon material with excellent electrical properties, which is known as the “superstar” of nanomaterials. It is widely used in materials science, energy, biomedicine, and so on. N-doped graphene has been successfully prepared and used for CO2RR. Sun et al. [67] directly synthesized N-doped graphene by free radical self-polymerization (Fig. 6a). The porosity and N concentration are adjusted by controlling the pyrolysis temperature. Compared with the template-free precursor, the catalyst has a higher surface area and larger pore size. When CO2 is reduced to CO, the FE of the catalyst is 83.0%, and the partial current density of CO is 1.79 mA/cm2 at overpotential of − 0.9 V (vs. RHE). The catalyst has abundant graphite-N species and a hierarchical pore structure, which enhances the activation performance of CO2RR.

Reproduced with permission from Ref. [67]. Copyright © 2021 Chemical Industry Press of China. b Nitrogen-doped porous carbon for CO2 electrocatalysis. Reproduced with permission from Ref. [68]. Copyright © 2019 Elsevier. c Nitrogen-doped porous carbon for CO2 electrocatalysis. Reproduced with permission from Ref. [69]. Copyright © 2020 Wiley

a Preparation of N-doped graphene catalyst and its application in CO2RR.

Porous carbon is a typical three-dimensional carbon material with a large specific surface area and pore volume. Recently, to broaden the application of porous carbon, heteroatom-doped porous carbon has been gradually developed and applied to CO2RR. Li et al. [68] developed and adopted an ammonia corrosion strategy to synthesize N-doped porous carbon (NPC) materials from coal as effective metal-free catalysts for CO2RR. The catalyst exhibits well-developed porous nanostructures and highly exposed N defects. They found that appropriate pyridine-N and pyrrole-N have synergistic effects on catalysis. At room temperature, the FE reaches 92% at overpotential of − 0.6 V (vs. RHE) (Fig. 6b). The catalyst can efficiently catalyze CO2 to produce CO, which provides a new idea for the preparation of porous carbon electrocatalysts from coal.

Metal–organic frameworks play an important role in the preparation of N-doped carbon materials. Ye et al. [69] prepared NPC with an oxygen-rich metal–organic framework (Zn-MOF-74) as the precursor, which has a highly porous structure and a large amount of active nitrogen (pyridine- and graphite-N). The NPC has a high concentration of CO2RR active sites, and the active sites can be adjusted. Because of the large pore size, the active center of the catalyst is highly exposed, providing a large number of active sites for CO2RR. The catalyst shows a low initial potential of − 0.35 V (vs. RHE) and a high FE of 98.4% at − 0.55 V (vs. RHE) (Fig. 6c).

B Doping Incorporating B atoms can significantly improve the properties of carbon-based materials. For example, doping diamond with B greatly improves its conductivity, corrosion resistance, oxidation resistance, and other properties. Based on this, B-doped carbon-based materials have been gradually developed. Sreekanth et al. [56] prepared a B-doped graphene catalyst with boric acid as the B source in an argon atmosphere at 900 °C for CO2RR with saturated bicarbonate as the electrolyte. The FE of HCOOH reached 66% at 1.4 V (vs. SCE) overpotential. B-doped carbon-based materials exhibit excellent electrocatalytic reduction properties for CO2. Nakata et al. [70] synthesized B-doped diamond (BDD) using trimethyl borate and acetone solution as the B and C sources, respectively. Under environmental conditions, the catalyst electrode can electrochemically reduce CO2 to HCHO in seawater. BDD shows a high FE of 74%.

F Doping F has stronger electronegativity than N, B, and S. Doping F can induce the polarization of adjacent carbon atoms, resulting in greater charge density, thus having stronger adsorption capacity for intermediates such as *COOH. Recently, it has been gradually proven that doping F atoms in carbon-based materials can significantly enhance electrocatalytic performance. In 2018, Xie et al. [57] synthesized a fluorocarbon (FC) catalyst with BP 2000 (a kind of oil, used as pristine carbon) and polytetrafluoroethylene. Because of F doping, FC has more structural defects. In addition, FC has shown excellent electrocatalytic activity for CO2RR. At a low overpotential of 510 mV (vs. RHE) and a small Tafel efficiency of 81 mV/dec, the maximum FE reaches 90%, surpassing the metal-free catalyst at that time. F doping activates adjacent carbon atoms and promotes the stability of key intermediate *COOH on F-doped carbon materials. The results also show that CO on FC shows high current density and H2 shows low current density, which indicates that F doping effectively inhibits hydrogen evolution.

S Doping There are currently few reports on single S-doped carbon-based materials used for CO2RR. Single S-doped carbon materials have many shortcomings when they are used in CO2RR. For example, surface vulcanization and sulfonation often lead to a significant decline in specific surface areas. In addition, S is easy to leach from the adsorbent in the S-doped carbon materials, resulting in the reduction of adsorption capacity, which affects their performance in CO2RR. Carbon-based materials co-doped with S and other atoms show good performance for CO2RR. The relevant introduction about S and other atoms co-doped carbon-based materials will be discussed in the “Polyatomic Doping” subsection.

Metal Monatomic Doping

Noble-metal catalysts show excellent performance in electrocatalysis. However, because of the scarcity of noble metals, the costs of preparing them are high. Transition metals have a d orbital electronic structure similar to noble metals, which is expected to reduce the preparation cost of catalysts. At present, researchers have prepared carbon-based material catalysts doped with metal atoms. Esmaeilira et al. [71] synthesized four transition-metal carbide nanoflakes (W2C, Mo2C, Nb2C, and V2C) by carburization and liquid stripping technology and used them for CO2RR to CH4. The results show that these materials have high selectivity for CH4. For W2C, the maximum current density of CH4 is − 421.63 mA/cm2, and the FE of CH4 is 82.7% ± 2%. The EE of CO2RR is about 62.3% under the minimum energy path of CO2 to CH4 by W2C. DFT calculations show that water dissociation, CO2 chemisorption, and C–O bond fracture are almost spontaneous on the W2C surface, which is the main reason for the high activity, selectivity, and low potential observed.

Polyatomic Doping

Single-atom doping into carbon-based materials can significantly improve the CO2 electrocatalytic activity of the catalyst. Compared with single-atom doping, multiple-atom doping into carbon-based materials can provide more active sites. Because of the synergistic effect between the doped atoms, the electrocatalytic activity for CO2 is more prominent.

Nonmetallic Polyatomic Doping

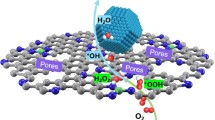

CO2RR over a metal-free N-doped carbon catalyst provides a solution for CO2 reuse. However, because of the low intrinsic reactivity of the N dopant, the overpotential is large and the selectivity is poor. In 2019, Pan et al. [59] synthesized N, F co-doped porous carbon layers by introducing the electron-rich F to activate pyridine-N sites (Fig. 7a). For CO, the catalyst achieves 90% FE within 40 h at a 490 mV (vs. RHE) low overpotential, which is significantly higher than that of the N–C catalyst without F. DFT calculations show that electron feeding from nearby F atoms increases the charge density and delocalizes the electron density of pyridine N states. The synergistic effect induced by doping creates a new way to control the performance of CO2RR.

Although F can significantly improve the catalytic activity, its toxicity limits its application. Pan’s group explored replacing F with S doping into carbon materials, prepared a N, S co-doped carbon layer catalyst, and used it for CO2RR [72]. They found that S addition can greatly improve the catalytic activity and selectivity of CO2 reduction. At a low overpotential of 490 mV (vs. RHE), the FE of CO is as high as 92%, and the partial current density of CO is 2.63 mA/cm2, which is much better than those of sulfur-free N–C (Fig. 7b). DFT calculations show that S addition to N–C leads to the formation of higher-density pyridine N as the active center for CO2 reduction. In addition, by doping S, the free energy barrier of the key intermediate *COOH can be reduced to improve the catalytic activity and selectivity. In the same year, Han et al. [73] prepared N, S dual-doped carbon nanoweb catalysts for CO2RR. They found that the catalyst can quickly convert CO2 to CO. At a low overpotential of 490 mV (vs. RHE), the FE is as high as 93.4%, and the partial current density is − 5.93 mA/cm2 (Fig. 7c). The minimum value of the Tafel slope is 93 mV/dec. In addition, within 20 h of electrolysis, the current density distribution is very stable, and the FE of CO exceeds 90%.

Metal Containing Polyatomic Doping

NGQDs show excellent catalytic performance in CO2RR. By co-doping with metal atoms, they can play a synergistic role and show excellent catalytic performance. Fu et al. [74] transferred surfactants on single-crystal gold nanoparticles to NGQDs through a wet chemical reduction method and synthesized NGQDs wound SCAu (NGQDs SCAu) (see Fig. 7a) for CO2RR. CO2 can be efficiently converted into CO at an ultra-low potential of − 0.25 V (vs. RHE). The maximum FE can reach 93%. The onset potential of CO is as low as − 0.15 V (vs. RHE) (Fig. 8a), which is much lower than that of Au nanocatalysts. DFT calculations show that this is due to the synergistic effect between pyridine N and SCAu in NGQDs, which improves the adsorption energy of *COOH on the catalyst, thus promoting the reduction of CO2 to CO.

Reproduced with permission from Ref. [74]. Copyright © 2018 ACS. b Fe, N co-doped carbon nanofibers for CO2RR. Reproduced with permission from Ref. [75]. Copyright © 2018 ACS. c Fe, N co-doped carbon nanotubes/carbon nanosheets for CO2RR. Reproduced with permission from Ref. [76]. Copyright © 2021 Wiley. d Double chain nickel-based catalyst Ni@NC@NCNT for CO2RR. Reproduced with permission from Ref. [78]. Copyright © 2021 ACS. e Zn, N co-doped graphene for CO2RR. Reproduced with permission from Ref. [79]. Copyright © 2018 Wiley

a Au, N co-doped graphene quantum dots for CO2RR.

Because of the expensiveness of Au, alternative cheaper transition metals are added to carbon-based materials to prepare metal-doped carbon catalysts. The common pure metal Fe has almost no CO2 electrocatalytic properties. However, the introduction of Fe into the carbon skeleton and the formation of metal-N co-doped carbon materials can activate their CO2 electrocatalytic properties. Cheng et al. [75] designed a Fe–N co-doped carbon nanofiber catalyst, which can effectively catalyze the CO2 to CO conversion (Fig. 8b). The process has nearly 100% selectivity and about 95% FE. The catalyst shows remarkable durability and stability. Pan et al. [76] designed a new nanostructured electrocatalyst by doping N and Fe through the calcination strategy protected by SiO2. The electrocatalyst consists of a CNT/carbon nanosheet (CNT/CNS) structure, which provides abundant N-induced defects and high active sites of Fe − N species for CO2RR. CNTs also provide a smooth path for charge transfer in CO2RR. At a low overpotential of 0.48 V (vs. RHE), the maximum FE of CO reaches 69%. The synergistic effect of structure design and doping optimization can effectively improve electrocatalytic activity and catalytic efficiency.

Ni and Fe belong to group VIIIB elements with similar properties. In recent years, Ni-based carbon materials have also been successfully synthesized. In 2021, Niu et al. [77] prepared a double-chain nickel-based catalyst (Ni@NC@NCNT) by solvothermal evaporation calcination. The performance of Ni@NC@NCNT for CO2RR is much better than that of single-chain Ni@NC. The catalyst has a large specific surface area and rich pyridine-N and Niδ+ sites to ensure its high CO2 adsorption capacity, as well as good stability. The FE of CO is as high as 94.1%, and the partial current density is as high as 48.0 mA/cm2 (Fig. 8c). After 43 h of continuous electrolysis, its performance remains unchanged.

In the same year, Gang et al. [78] prepared a mixed CNS/CNT catalyst with Ni, N co-doped by one-step chemical vapor deposition (CVD) (Fig. 8d). In the CVD process, Ni nanoparticles were coated with a graphite carbon layer, which inhibited the competitive hydrogen evolution reaction and achieved high CO selectivity. The partial current density of CO is 28.9 mA/cm2, and the FE is 91% at − 0.74 V (vs. RHE) overpotential at room temperature. When the applied voltage is − 2.0 V (vs. RHE), the selectivity for CO is more than 85%. These carbon-based catalysts show excellent performance in the current density and selectivity of CO.

Zn is a common transition metal, and Zn-doped carbon materials also show excellent CO2RR characteristics. Chen et al. [79] prepared single center zinc coordinated nitrogen co-doped graphene (Zn–N–G) and used it to catalyze CO2 to produce CO (Fig. 8e). The Zn–N–G catalyst showed excellent intrinsic activity for CO2 reduction. At an overpotential of 0.39 V (vs. RHE), the FE is 91%. The isolated Zn–Nx exists in the catalyst and is the key active site for CO formation. This work provides a basis for further understanding of the active sites on metal–N–C catalysts.

Sun et al. [80] achieved high efficiency of CO2RR to CO by adjusting the interface between CdO and carbon black (CB). Through the performance test of CO2RR to CO by CdO/CB composites, they found that CdO/CB composites with 20 wt% CdO can obtain a total FE of 92.7% at − 1.0 V (vs. RHE) potential, which is much higher than that of pure CdO (69.5%) under the same conditions. The FE of CO is up to 87.4%. They found that the high catalytic performance of CdO/CB composites is attributed to the interface and high contact area between CdO and CB. In addition, the catalyst showed super stable catalytic activity.

Monatomic catalysts have become a research hotspot because of their high atomic efficiency and good activity. However, in the catalytic process, the influence of the support structure in monatomic catalysts is often not noticed. Xiong et al. [81] synthesized a series of hollow mesoporous carbon spheres supported Ni-N4 monatomic catalysts (Ni/HMCS-3–800) with different support structures and with excellent catalytic activities for CO2RR (Fig. 9a). In the potential range of –0.7 to –1.1 V (vs. RHE), the FE of the catalyst for CO is as high as 95%. They found that the shell thickness and compactness of carbon spheres effectively regulate the chemical environment of N-doped species in the carbon skeleton and promote the activation of CO2 molecules. This provides a new idea for improving the catalytic performance of monatomic catalysts.

Reproduced with permission from Ref. [81]. Copyright © 2020 Wiley. b CNT/ Ni@mC catalyst for CO2RR. Reproduced with permission from Ref. [82]. Copyright © 2022 Elsevier. c ZrO2/NC and CeO2/NC catalysts for CO2RR. Reproduced with permission from Ref. [65]. Copyright © 2021 Springer. d Ultra thin bismuth oxide nanosheet/carbon foam catalyst for CO2RR. Reproduced with permission from Ref. [85]. Copyright © 2020 Wiley–VCH

a Hollow mesoporous carbon spheres supported Ni-N4 catalyst for CO2RR.

Recently, Du and Chen [82] reported that CNT/Ni@mC were successfully prepared by modifying CNTs with a layer of mesoporous carbon shell anchored by nickel (Ni) nanoparticles. Dispersed Ni nanoparticles and N doping in mesoporous carbon provide abundant active sites, so the catalyst shows very excellent catalytic performance. Selective reduction of CO2 to CO obtains a maximum FE of CO of 98% at the crossing point of − 0.81 V (vs. RHE) (Fig. 9b) and partial current density of CO of 60 mA/cm2.

In addition, Cu shows excellent performance in CO2RR. In 2021, Li et al. [83] dispersed atomic copper on N-doped carbon nanosheets and prepared Cu − N − C composites by the metal-organic skeleton derivation method. Because of the unique structural characteristics of monatomic Cu, the catalyst can more effectively promote CO2RR. The Cu − N − C catalyst has better catalytic performance than the traditional copper electrode, and the yield is as high as 71%. Also, Cometto et al. [84] modified exfoliated graphite carbon nitride (GCN) with a single copper atom and used it for CO2RR. Experimental and theoretical studies determined the adsorption sites and coordination of copper atoms. They found GCN to be a promising substrate that can effectively stabilize metal atoms because of the strong Cu–N interaction in its structure.

Metal oxides also show excellent performance in CO2RR. Shi et al. [65] synthesized metal oxide/N-doped carbon catalysts (ZrO2/NC, CeO2/NC) with high activity by surface pyrolysis. In CO2RR, the ZrO2/NC and CeO2/NC catalysts have higher catalytic activity than NC catalysts without metal oxides. At room temperature, the maximum FE of CO reaches 90%, and the partial current density of CO is 5.5 mA/cm2 (Fig. 9c). They found that the metal oxide carbon interface plays an important role in improving the catalytic activity and selectivity of CO. Meng et al. [85] designed an integrated three-dimensional bismuth oxide ultra-thin nanosheet/carbon foam electrode through the sponge effect and electrically reduced CO2 to formic acid with high efficiency and selectivity for the first time. The catalyst has a unique three-dimensional array foam structure, which realizes high-efficiency mass transfer by optimizing the exposed active sites. The electrode has achieved excellent partial current density, high FE (up to 94.1%), and high energy conversion efficiency (up to 60.3%), as shown in Fig. 9d.

Conclusions and Prospects

Herein, research progress on carbon-based materials doped with different heteroatoms in CO2RR is reviewed in detail, and breakthroughs in identifying active sites, improving catalytic activities, and clarifying the catalytic mechanism are comprehensively analyzed. The catalytic activity of carbon-based materials for CO2RR is highly dependent on the carbon structure and heteroatoms. The synthesis of efficient carbon-based catalysts needs to be adjusted, and the carbon/heteroatom precursors should be optimized. The goal is to enhance the catalytic activity, clarify the catalytic mechanism, and improve the product yield. However, we still face many major challenges. Therefore, the prospect of efficient CO2RR is discussed in this paper.

-

(1)

Reasonably designed and prepared bimetallic-doped carbon-based catalysts. When the two metals are made into an alloy, the product distribution of CO2RR will not show superposition but will produce a highly selective product distribution different from that of a single metal. Reasonable design and preparation of bimetallic carbon-based catalysts may regulate the electronic structure of the metal interface, effectively improve the electrochemical performance, and achieve high selectivities of products.

-

(2)

Constructing a carbon-based catalyst with a core–shell structure. The catalyst with this structure may change the binding strength between the catalyst and CO2RR intermediates by adjusting the surface electron distribution while possibly changing the local atomic arrangement of the active site, thereby affecting the selective adsorption of different intermediates. Hence, carbon-based materials with a core–shell structure may greatly improve the performance of CO2RR.

-

(3)

Introducing a cocatalyst into a carbon-based catalyst may greatly improve its catalytic activity. The cocatalyst itself has no catalytic activity, or the catalytic activity is very low, which can be ignored. Because of the synergistic effect, the introduction of a cocatalyst may change the adsorption and desorption strength of intermediates, so the catalyst as a whole shows unexpected catalytic performance and achieves the effect of 1 + 1 > 2. The catalytic activity of the catalyst may be greatly improved, as well as the selectivity or stability of the product.

-

(4)

Optimization of the electrocatalysis system. At present, electrocatalytic CO2 reduction is mostly carried out in an H-type electrolyzer. As the reaction proceeds, the products gradually increase, and the local microenvironment in the electrolytic cell changes, which will restrict the reaction efficiency. In addition, the electrolyte in the electrocatalysis system is mostly an aqueous solution, which limits the dissolution of CO2. Based on this, organic, seawater, and solid electrolytes have been gradually applied to the CO2RR system, which has great potential. Hence, it is particularly important to optimize the electrocatalysis system and find a suitable electrolyte.

References

Aresta M, Dibenedetto A, Angelini A (2014) Catalysis for the valorization of exhaust carbon: from CO2 to chemicals, materials, and fuels. Technological use of CO2. Chem Rev 114(3):1709–1742

Younas M, Loong Kong L, Bashir MJK et al (2016) Recent advancements, fundamental challenges, and opportunities in catalytic methanation of CO2. Energy Fuels 30(11):8815–8831

Zhao K, Quan X (2021) Carbon-based materials for electrochemical reduction of CO2 to C2+ oxygenates: recent progress and remaining challenges. ACS Catal 11(4):2076–2097

Gong LL (2021) Research on the rational design and catalytic mechanism of high performance CO2 reduction electrocatalyst. Beijing University of Chemical Technology, Beijing, China

Shi JF, Jiang YJ, Jiang ZY et al (2015) Enzymatic conversion of carbon dioxide. Chem Soc Rev 44(17):5981–6000

Li JS, Tian Y, Zhou YN et al (2020) Abiotic-biological hybrid systems for CO2 conversion to value-added chemicals and fuels. Trans Tianjin Univ 26(4):237–247

Fan Q, Zhang ML, Jia MW et al (2018) Electrochemical CO2 reduction to C2+ species: heterogeneous electrocatalysts, reaction pathways, and optimization strategies. Mater Today Energy 10:280–301

Gao DF, Arán-Ais RM, Jeon HS et al (2019) Rational catalyst and electrolyte design for CO2 electroreduction towards multicarbon products. Nat Catal 2(3):198–210

Grice KA (2017) Carbon dioxide reduction with homogenous early transition metal complexes: opportunities and challenges for developing CO2 catalysis. Coord Chem Rev 336:78–95

Kuhl KP, Cave ER, Abram DN et al (2012) New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ Sci 5(5):7050–7059

Tian PF, Su JJ, Song Y et al (2022) Electroreduction of carbon dioxide by heterogenized cofacial porphyrins. Trans Tianjin Univ 28(1):73–79

Dey GR (2007) Chemical reduction of CO2 to different products during photo catalytic reaction on TiO2 under diverse conditions: an overview. J Nat Gas Chem 16(3):217–226

Li K, Peng BS, Peng TY (2016) Recent advances in heterogeneous photocatalytic CO2 conversion to solar fuels. ACS Catal 6(11):7485–7527

Lin JL, Pan ZM, Wang XC (2014) Photochemical reduction of CO2 by graphitic carbon nitride polymers. ACS Sustainable Chem Eng 2(3):353–358

Low J, Cheng B, Yu JG (2017) Surface modification and enhanced photocatalytic CO2 reduction performance of TiO2: a review. Appl Surf Sci 392:658–686

Chen YH, Kanan MW (2012) Tin oxide dependence of the CO2 reduction efficiency on tin electrodes and enhanced activity for tin/tin oxide thin-film catalysts. J Am Chem Soc 134(4):1986–1989

Kornienko N, Zhao YB, Kley CS et al (2015) Metal-organic frameworks for electrocatalytic reduction of carbon dioxide. J Am Chem Soc 137(44):14129–14135

Gao S, Lin Y, Jiao XC et al (2016) Partially oxidized atomic cobalt layers for carbon dioxide electroreduction to liquid fuel. Nature 529(7584):68–71

Zou XL, Liu MJ, Wu JJ et al (2017) How nitrogen-doped graphene quantum dots catalyze electroreduction of CO2 to hydrocarbons and oxygenates. ACS Catal 7(9):6245–6250

Whipple DT, Kenis PJA (2010) Prospects of CO2 utilization via direct heterogeneous electrochemical reduction. J Phys Chem Lett 1(24):3451–3458

Liu AM, Gao MF, Ren XF et al (2020) Current progress in electrocatalytic carbon dioxide reduction to fuels on heterogeneous catalysts. J Mater Chem A 8(7):3541–3562

Olah GA, Prakash GKS, Goeppert A (2011) Anthropogenic chemical carbon cycle for a sustainable future. J Am Chem Soc 133(33):12881–12898

Lu Q, Rosen J, Jiao F (2015) Nanostructured metallic electrocatalysts for carbon dioxide reduction. ChemCatChem 7(1):38–47

Zhu DD, Liu JL, Qiao SZ (2016) Recent advances in inorganic heterogeneous electrocatalysts for reduction of carbon dioxide. Adv Mater 28(18):3423–3452

Fan L, Xia C, Yang FQ et al (2020) Strategies in catalysts and electrolyzer design for electrochemical CO2 reduction toward C 2+ products. Sci Adv 6(8):eaay3111

Jia C, Dastafkan K, Ren WH et al (2019) Carbon-based catalysts for electrochemical CO2 reduction. Susta Energy Fuels 3(11):2890–2906

Chen ZF, Chen CC, Weinberg DR et al (2011) Electrocatalytic reduction of CO2 to CO by polypyridyl ruthenium complexes. Chem Commun 47(47):12607–12609

Diercks CS, Lin S, Kornienko N et al (2018) Reticular electronic tuning of porphyrin active sites in covalent organic frameworks for electrocatalytic carbon dioxide reduction. J Am Chem Soc 140(3):1116–1122

Zhang ZY, Lu XQ, Niu CX et al (2022) Clarifying catalytic behaviors and electron transfer routes of electroactive biofilm during bioelectroconversion of CO2 to CH4. Fuel 310:122450

Sun XF, Kang XC, Zhu QG et al (2016) Very highly efficient reduction of CO2 to CH4 using metal-free N-doped carbon electrodes. Chem Sci 7(4):2883–2887

Dongare S, Singh N, Bhunia H (2021) Electrocatalytic reduction of CO2 to useful chemicals on copper nanoparticles. Appl Surf Sci 537:148020

Marepally BC, Ampelli C, Genovese C et al (2017) Role of small Cu nanoparticles in the behaviour of nanocarbon-based electrodes for the electrocatalytic reduction of CO2. J CO2 Util 21:534–542

Kumar N, Seriani N, Gebauer R (2020) DFT insights into electrocatalytic CO2 reduction to methanol on α-Fe2O3(0001) surfaces. Phys Chem Chem Phys 22(19):10819–10827

Ma T, Fan Q, Tao HC et al (2017) Heterogeneous electrochemical CO2 reduction using nonmetallic carbon-based catalysts: current status and future challenges. Nanotechnology 28(47):472001

Wu JJ, Ma SC, Sun J et al (2016) A metal-free electrocatalyst for carbon dioxide reduction to multi-carbon hydrocarbons and oxygenates. Nat Commun 7:13869

Munir S, Varzeghani AR, Kaya S (2018) Electrocatalytic reduction of CO2 to produce higher alcohols. Sustain Energy Fuels 2(11):2532–2541

Wang B, Yang FL, Dong YP et al (2020) Cu@porphyrin-COFs nanorods for efficiently photoelectrocatalytic reduction of CO2. Chem Eng J 396:125255

Zhu M, Ge QF, Zhu XL (2020) Catalytic reduction of CO2 to CO via reverse water gas shift reaction: recent advances in the design of active and selective supported metal catalysts. Trans Tianjin Univ 26(3):172–187

Liu S, Yang HB, Su X et al (2019) Rational design of carbon-based metal-free catalysts for electrochemical carbon dioxide reduction: a review. J Energy Chem 36:95–105

Wang W, Shang L, Chang GJ et al (2019) Intrinsic carbon-defect-driven electrocatalytic reduction of carbon dioxide. Adv Mater 31(19):e1808276

Liu JP, Peng WC, Li Y et al (2020) 2D MXene-based materials for electrocatalysis. Trans Tianjin Univ 26(3):149–171

Silva WO, Silva GC, Webster RF et al (2019) Electrochemical reduction of CO2 on nitrogen-doped carbon catalysts with and without iron. ChemElectroChem 6(17):4626–4636

Ma T, Fan Q, Li X et al (2019) Graphene-based materials for electrochemical CO2 reduction. J CO2 Util 30:168–182

Yang NJ, Waldvogel SR, Jiang X (2016) Electrochemistry of carbon dioxide on carbon electrodes. ACS Appl Mater Interfaces 8(42):28357–28371

Dai LM (2017) Carbon-based catalysts for metal-free electrocatalysis. Curr Opin Electrochem 4(1):18–25

Liu XE, Dai LM (2016) Carbon-based metal-free catalysts. Nat Rev Mater 1:16064

Duan X, Xu J, Wei Z et al (2017) Metal-free carbon materials for CO2 electrochemical reduction. Adv Mater 29(41):1701784

Huan TN, Prakash P, Simon P et al (2016) CO2 reduction to CO in water: carbon nanotube-gold nanohybrid as a selective and efficient electrocatalyst. Chemsuschem 9(17):2317–2320

Vasileff A, Yao Z, Shi ZQ (2017) Carbon solving carbon’s problems: recent progress of nanostructured carbon-based catalysts for the electrochemical reduction of CO2. Adv Energy Mater 7(21):1700759

Wu JJ, Sharifi T, Gao Y et al (2019) Emerging carbon-based heterogeneous catalysts for electrochemical reduction of carbon dioxide into value-added chemicals. Adv Mater 31(13):e1804257

Du J, Zhang P, Liu HZ (2021) Electrochemical reduction of carbon dioxide to ethanol: an approach to transforming greenhouse gas to fuel source. Chem Asian J 16(6):588–603

Kumar B, Asadi M, Pisasale D et al (2013) Renewable and metal-free carbon nanofibre catalysts for carbon dioxide reduction. Nat Commun 4:2819

Li WL, Seredych M, Rodríguez-Castellón E et al (2016) Metal-free nanoporous carbon as a catalyst for electrochemical reduction of CO2 to CO and CH4. Chemsuschem 9(6):606–616

Varela AS, Ju W, Strasser P (2018) Molecular nitrogen-carbon catalysts, solid metal organic framework catalysts, and solid metal/nitrogen-doped carbon (MNC) catalysts for the electrochemical CO2 reduction. Adv Energy Mater 8(30):1802905

Wang HX, Chen YB, Hou XL et al (2016) Nitrogen-doped graphenes as efficient electrocatalysts for the selective reduction of carbon dioxide to formate in aqueous solution. Green Chem 18(11):3250–3256

Sreekanth N, Nazrulla MA, Vineesh TV et al (2015) Metal-free boron-doped graphene for selective electroreduction of carbon dioxide to formic acid/formate. Chem Commun 51(89):16061–16064

Xie JF, Zhao XT, Wu MX et al (2018) Metal-free fluorine-doped carbon electrocatalyst for CO2 reduction outcompeting hydrogen evolution. Angew Chem Int Ed Engl 57(31):9640–9644

Liu YM, Zhang YJ, Cheng K et al (2017) Inside cover: selective electrochemical reduction of carbon dioxide to ethanol on a boron- and nitrogen-Co-doped nanodiamond (angew. chem. int. ed. 49/2017). Angew Chem Int Ed 56(49):15474

Pan FP, Li BY, Xiang XM et al (2019) Efficient CO2 electroreduction by highly dense and active pyridinic nitrogen on holey carbon layers with fluorine engineering. ACS Catal 9(3):2124–2133

Yang HP, Wu Y, Lin Q et al (2018) Composition tailoring via N and S Co-doping and structure tuning by constructing hierarchical pores: metal-free catalysts for high-performance electrochemical reduction of CO2. Angew Chem Int Ed Engl 57(47):15476–15480

Zhang TY, Li WT, Huang K et al (2021) Regulation of functional groups on graphene quantum dots directs selective CO2 to CH4 conversion. Nat Commun 12:5265

Sharma PP, Wu JJ, Yadav RM et al (2015) Nitrogen-doped carbon nanotube arrays for high-efficiency electrochemical reduction of CO2: on the understanding of defects, defect density, and selectivity. Angew Chem Int Ed Engl 54(46):13701–13705

Wu JJ, Yadav RM, Liu MJ et al (2015) Achieving highly efficient, selective, and stable CO2 reduction on nitrogen-doped carbon nanotubes. ACS Nano 9(5):5364–5371

Shi H, Pan H, Cheng YY et al (2021) Imine-nitrogen-doped carbon nanotubes for the electrocatalytic reduction of flue gas CO2. ChemElectroChem 8(10):1792–1797

Shi H, Cheng Y, Kang P (2021) Metal oxide/nitrogen-doped carbon catalysts enables highly efficient CO2 electroreduction. Trans Tianjin Univ 27:269–277

Li HQ, Xiao N, Hao MY et al (2018) Efficient CO2 electroreduction over pyridinic-N active sites highly exposed on wrinkled porous carbon nanosheets. Chem Eng J 351:613–621

Sun MD, Bian ZY, Cui WW et al (2022) Pyrolyzing soft template-containing poly(ionic liquid) into hierarchical N-doped porous carbon for electroreduction of carbon dioxide. Chin J Chem Eng 43:192–201

Li C, Wang YW, Xiao N et al (2019) Nitrogen-doped porous carbon from coal for high efficiency CO2 electrocatalytic reduction. Carbon 151:46–52

Ye L, Ying YR, Sun DR et al (2020) Highly efficient porous carbon electrocatalyst with controllable N-species content for selective CO2 reduction. Angew Chem Int Ed Engl 59(8):3244–3251

Nakata K, Ozaki T, Terashima C et al (2014) High-yield electrochemical production of formaldehyde from CO2 and seawater. Angewandte Chemie Int Ed Engl 53(3):871–874

Esmaeilirad M, Baskin A, Kondori A et al (2021) Gold-like activity copper-like selectivity of heteroatomic transition metal carbides for electrocatalytic carbon dioxide reduction reaction. Nat Commun 12:5067

Pan FP, Li BY, Deng W et al (2019) Promoting electrocatalytic CO2 reduction on nitrogen-doped carbon with sulfur addition. Appl Catal B Environ 252:240–249

Han H, Park S, Jang D et al (2020) Electrochemical reduction of CO2 to CO by N, S dual-doped carbon nanoweb catalysts. Chemsuschem 13(3):539–547

Fu JJ, Wang Y, Liu J et al (2018) Low overpotential for electrochemically reducing CO2 to CO on nitrogen-doped graphene quantum dots-wrapped single-crystalline gold nanoparticles. ACS Energy Lett 3(4):946–951

Cheng QQ, Mao K, Ma LS et al (2018) Encapsulation of iron nitride by Fe-N-C shell enabling highly efficient electroreduction of CO2 to CO. ACS Energy Lett 3(5):1205–1211

Pan FP, Zhao HL, Deng W et al (2018) A novel N, Fe-Decorated carbon nanotube/carbon nanosheet architecture for efficient CO2 reduction. Electrochim Acta 273:154–161

Niu YJ, Zhang CH, Wang YY et al (2021) Confining chainmail-bearing Ni nanoparticles in N-doped carbon nanotubes for robust and efficient electroreduction of CO2. Chemsuschem 14(4):1140–1154

Gang Y, Sarnello E, Pellessier J et al (2021) One-step chemical vapor deposition synthesis of hierarchical Ni and N Co-doped carbon nanosheet/nanotube hybrids for efficient electrochemical CO2 reduction at commercially viable current densities. ACS Catal 11(16):10333–10344

Chen ZP, Mou KW, Yao SY et al (2018) Zinc-coordinated nitrogen-codoped graphene as an efficient catalyst for selective electrochemical reduction of CO2 to CO. Chemsuschem 11(17):2944–2952

Wang L, Li X, Hong S et al (2022) Efficient electrocatalytic CO2 reduction to CO by tuning CdO-carbon black interface. J Chinese Universities 43(7):20220317

Xiong WF, Li HF, Wang HM et al (2020) Hollow mesoporous carbon sphere loaded Ni-N4 single-atom: support structure study for CO2 electrocatalytic reduction catalyst. Small 16(41):e2003943

Du J, Chen AB (2022) Ni nanoparticles confined by yolk-shell structure of CNT-mesoporous carbon for electrocatalytic conversion of CO2: switching CO to formate. J Energy Chem 70:224–229

Li SM, Shi Y, Zhang JJ et al (2021) Atomically dispersed copper on N-doped carbon nanosheets for electrocatalytic synthesis of carbamates from CO2 as a C1 source. Chemsuschem 14(9):2050–2055

Cometto C, Ugolotti A, Grazietti E et al (2021) Copper single-atoms embedded in 2D graphitic carbon nitride for the CO2 reduction. Npj 2D Mater Appl 5:63

Meng FL, Zhang Q, Liu KH et al (2020) Integrated bismuth oxide ultrathin nanosheets/carbon foam electrode for highly selective and energy-efficient electrocatalytic conversion of CO2 to HCOOH. Chemistry 26(18):4013–4018

Acknowledgments

This work was financially supported by the Natural Science Foundation of Hebei Province (B02020208088, H2020206514, and B2021208074), the S&T Program of Hebei Province (20544401D, 20314401D, 206Z4406G, 21314402D, 21344601D, 22344402D, and 22373709D), and the Research Start-up Funding at Hebei University of Science and Technology (1181381).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ji, Y., Du, J. & Chen, A. Review on Heteroatom Doping Carbonaceous Materials Toward Electrocatalytic Carbon Dioxide Reduction. Trans. Tianjin Univ. 28, 292–306 (2022). https://doi.org/10.1007/s12209-022-00332-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-022-00332-z