Abstract

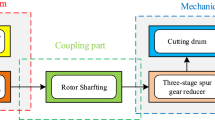

In order to study the dynamic characteristics of cutting head and cantilever system, a nonlinear dynamic model with a 13 degrees of freedom (13-DOF) lateral torsional coupled cutting head-rotor-bearing system (CHRBS) is established. The nonlinear coupled factors of spline clearance and bearing contact force are mainly considered, the dynamic analysis of CHRBS under time-varying load is carried out. The results show that there is no positive correlation between the cutting rock thickness and the states of chaotic motion and quasiperiodic motion. The system is in the two states mentioned above when in low speed region. With the increase of rotational speed, the chaotic motion becomes periodic motion. When the hardness of rock is lower, increasing rotational speed can reduce the vibration of the system, and the cutting thickness can be increased to improve the productivity and lump rock rate. As the hardness of rocks increases, the coupled system shows complex dynamic characteristics when the rotational speed changes from low to high, and the vibration increased. When cutting hard rock, the cutting speed should be increased. However, when the speed is too high, the cutting torque of system becomes smaller. In the case of cutting hard rock, reasonable rotational speed should be chosen between improving stability and increasing cutting force. The dynamic analysis results provide strong support for the vibration reduction and dynamic design of roadheader.

Similar content being viewed by others

References

H. Schneider, Criteria for selecting a boom-type roadheader, Mining Magazine (1988).

H. Matti, Rock Excavation Handbook, Sandvik Tamrock (1999).

L. J. Zhao, T. Zhen, S. Ying and Z. H. Zhou, Vibration characteristics of a longitudinal roadheader, Journal of Vibration & Shock, 32 (2013) 17–20

J. T. Alvarez, M. M. Alvarez and R. R. Diez, Experimental results of a low-power roadheader driving a gallery with different types of rock at the face, Tunnelling and Underground Space Technology, 18 (2003) 395–404

O. Acaroglu and H. Ergin, A new method to evaluate roadheader operational stability, Tunnelling and Underground Space Technology, 21 (2006) 172–179

H. Ergin and O. Acaroglu, The effect of machine design parameters on the stability of a roadheader, Tunnelling and Underground Space Technology, 22 (2007) 80–89

H. X. Jiang, S. Y. Liu, C. L. Du and K. D. Gao, Numerical simulation of rock fragmentation process by roadheader pick, Journal of Vibroengineering, 15 (2013) 1807–1817

E. Avunduk, D. Tumac and A. K. Atalay, Prediction of roadheader performance by artificial neural network, Tunnelling and Underground Space Technology, 44 (2014) 3–9

A. Salsani, J. Daneshian, S. Shariati, A. Yazdani-Chamzini and M. Taheri, Predicting roadheader performance by using artificial neural network, Neural Computing & Applications, 24 (2014) 1823–1831

H. Wang, D. Y. Sun and D. T. Qin, A new continuously variable transmission system applied to transmission system of the roadheader's cutting unit, Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science, 231 (2017) 3590–3600

H. Zhang, M. L. Wang, Q. K. Han and W. Sun, Dynamic behaviors of the cutterhead driving system in tunneling boring machine with impact, Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science, 230 (2016) 2427–2437

C. L. Hua, Z. S. Rao, N. Ta and Z. C. Zhu, Nonlinear dynamics of rub-impact on a rotor-rubber bearing system with the Stribeck friction model, Journal of Mechanical Science and Technology, 29 (2015) 3109–3119

C. L. Hua, N. Ta and Z. S. Rao, Dynamic characteristics analysis of a rub-impact rubber bearing-shaft system, Journal of Vibration and Control, 21 (2015) 388–401

M. A. Abuzaid, M. E. Eleshaky and M. G. Zedan, Effect of partial rotor-to-stator rub on shaft vibration, Journal of Mechanical Science and Technology, 23 (2009) 170–182

I. Eski, Vibration analysis of drilling machine using proposed artificial neural network predictors, Journal of Mechanical Science and Technology, 26 (2012) 3037–3046

H. Wu, Q. Zhou, Z. M. Zhang and Q. An, Vibration analysis on the rolling element bearing-rotor system of an air blower, Journal of Mechanical Science and Technology, 26 (2012) 653–659

J. Z. Huo, H. Y. Wu, J. Yang, W. Sun, G. Q. Li and X. L. Sun, Multi-directional coupling dynamic characteristics analysis of TBM cutterhead system based on tunnelling field test, Journal of Mechanical Science and Technology, 29 (2015) 3043–3058

C. L. Hua, G. H. Cao, Z. S. Rao, N. Ta and Z. C. Zhu, Coupled bending and torsional vibration of a rotor system with nonlinear friction, Journal of Mechanical Science and Technology, 31 (2017) 2679–2689

A. Kahraman, A spline joint formulation for drive train torsional dynamic models, Journal of Sound and Vibration, 241 (2001) 328–336

K. W. Chase, C. D. Sorensen and B. J. K. DeCaires, Variation analysis of tooth engagement and loads in involute splines, IEEE Transactions on Automation Science and Engineering, 7 (2010) 746–754

R. F. Li and J. J. Wang, Gear System Dynamics Vibration, Shock, Noise, Beijing: Science Press (1997).

X. H. Li, Key Technology Research on Roadhearder Cutting Head, Beijing: Machinery Industry Press (2008).

T. A. Harris and M. N. Kotzalas, Rolling bearing analysis, Fifth edition, Advanced Concepts of Bearing Technology, Boca Raton, London, New York: Taylor & Francis Group (2006).

J. Liu and Y. M. Shao, Dynamic modeling for rigid rotor bearing systems with a localized defect considering additional deformations at the sharp edges, Journal of Sound and Vibration, 398 (2017) 84–102

J. Liu and Y. M. Shao, An improved analytical model for a lubricated roller bearing including a localized defect with different edge shapes, Journal of Vibration and Control, 24 (2018) 3894–3907

J. Liu, Y. M. Shao and T. C. Lim, Vibration analysis of ball bearings with a localized defect applying piecewise response function, Mechanism and Machine Theory, 56 (2012) 156–169

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Daeil Kwon

Zhi-Long Huang is currently a doctoral student at Northeastern University in China. His research interests include dynamics of multi-body systems, vibration in mechanics, nonlinear systems, and dynamics of synchronizing systems.

Zhong-Chao Zhang is currently a Ph.D. candidate at Northeastern University in China. His research interests including vibration in mechanics, nonlinear systems and numerical simulation.

Rights and permissions

About this article

Cite this article

Huang, Z., Zhang, Z., Li, Y. et al. Nonlinear dynamic analysis of cutting head-rotor-bearing system of the roadheader. J Mech Sci Technol 33, 1033–1043 (2019). https://doi.org/10.1007/s12206-019-0106-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-019-0106-7