Abstract

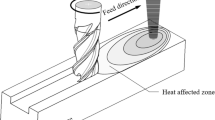

Kevlar laminates are difficult to machine using conventional machining methods because of their thermal and mechanical properties. Laser cutting offers advantages over conventional machining methods, such as precision of operation, non-frictional processing, and operational cost. This provides the motivation for the present study, which reports on laser cutting of Kevlar laminates of different thicknesses. The first and second law efficiencies of the cutting process are formulated and predicted in line with the experimental parameters. The laser cut surfaces are examined using optical and electron scanning microscopes. It is demonstrated that the first and second law efficiencies improve at high laser cutting speeds and low laser output power levels. For these conditions parallel sided kerfs with no sideways burning are produced.

Similar content being viewed by others

References

A. N. Shuaib, F. A. Al-Sulaiman and F. Hamid, Machinability of Kevlar® 49 composite laminates while using standard TiN coated HSS drills, Machining Science and Technology, 8(3) (2004) 449–467.

S. C. Lin and I. K. Chen, Drilling carbon fiber-reinforced composite material at high speeds, Wear, 194 (1996) 156–162.

F. Al-Sulaiman and B. S. Yilbas, Laser treatment of a carbon/carbon reinforced composite, Lasers in Engineering, 15(1–2) (2005) 119–127.

C. T. Pan and H. Hocheng, Prediction of extent of heat affected zone in laser grooving of unidirectional fiberreinforced plastics, Journal of Engineering Materials and Technology, 120 (1998) 321–327.

T. Hirogaki, E. Aoyama, H. Inoue, K. Ogawa, S. Maeda and T. Katayama, Laser drilling of blind via holes in aramid and glass/epoxy composites for multi-layer printed wiring boards, Composites: Part A 32 (2001) 963–968.

S. Akihiro and M. Noriaki Mechanical properties and microstructure of poly (ethylene terephalate) microfiber prepared by carbon dioxide laser heating, J. Applied Polymer Science, 90 (2003) 1955–1958.

M. Weinhold and D. J. Powell, High speed laser ablation of microvia holes in non-woven aramid reinforced printed wiring boards to reduce cost, Circuit World, 22(3) (1996) 16–22.

A. Di Ilio and V. Tagliaferri, Thermal damage in laser cutting of (0/90)2s aramid/epoxy laminates, Composites, 20(2) (1989) 115–119.

T. A. El-Taweel, A. M. Abdel-Maaboud, B. S. Azzam and A. E. Mohammad, Parametric studies on the CO2 laser cutting of Kevlar-49 composite, The International Journal of Advanced Manufacturing Technology, 40(9–10) (2009) 907–917.

B. Fahmi, M. N. Sanjeeva and F. M. Zimmermann, Enhancement of fiber-matrix adhesion by laser ablationinduced surface microcorrugation, Journal of Materials Science, 43(16) (2008) 5585–5590.

L. M. Galantucci and F. Giusti, Excimer laser cutting: Experimental characterization and 3D numerical modeling for polyester resins, CIRP Annals-Manufacturing Technology, 47 (1998) 141–144.

A. Kar, J. A. Rothenflue and W. P. Latham, Scaling laws for thick-section cutting with a chemical oxygen-iodine laser, Journal of Laser Applications, 9(6) (1997) 279–286.

F. Al-Sulaiman, B. S. Yilbas, F. C. Karakas, M. Ahsan and E. M. A. Mokheimer, Laser hole cutting in Kevlar: modeling and quality assessment, The International Journal of Advanced Manufacturing Technology, 38(11–12) (2007) 1125–1136.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Tong Seop Kim

Bekir Sami Yilbas received his PhD in Mechanical Engineering from Birmingham University. He was awarded the Doctor of Engineering Degree in 2005 by Birmingham University due to his significant contribution to his field of study. He has published 375 journal papers in reputable international journals and presented over 60 papers at international conferences. He has served as an editorial board member of international journals, including the International Journal of Machine Tool and Manufacture Design, Research and Application, International Journal of Subsurface Sensing Technologies and Applications, Journal of Materials Processing Technology, Journal of Achievements in Materials and Manufacturing Engineering, International Journal of Nanomanufacturing, and Archives of Materials Science and Engineering. He has received numerous awards as recognition of his research work.

Rights and permissions

About this article

Cite this article

Yilbas, B.S., Sahin, A.Z., Chatwin, C. et al. Laser cutting of Kevlar laminates: First and second law analysis. J Mech Sci Technol 25, 855–862 (2011). https://doi.org/10.1007/s12206-011-0218-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-011-0218-1