Abstract

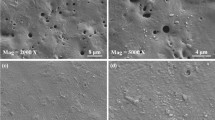

This study examined the tribological behavior of journal bearings made from polytetrafluoroethylene (PTFE) composites and aluminum (Al) alloys. The PTFE composite journal bearings consisted of a steel backing with a thickness of 1.6 mm, a middle layer of sintered porous bronze with a thickness of 0.24∼0.27 mm, and a surface layer of PTFE filled with fluorinated ethylene propylene (FEP) powder and carbon fibers with a thickness 0.06∼0.14 mm. The other was an aluminum alloy journal bearing consisted of a steel backing with a thickness of 1.5 mm and a surface layer of an Al-6Sn-6Si alloy with a thickness 0.35∼0.75 mm. A series of lubrication tests were performed using a journal bearing tester under various normal loads. The tribological properties for each journal bearing were evaluated by measuring the lubricant oil temperature and friction coefficient as a function of the applied normal load. In addition, the chemical compositions and microstructures of the journal bearing materials used in this study was analyzed by inductively coupled plasma (ICP), optical microscopy (OM), and scanning electron microscopy (SEM), respectively. The experimental results showed that the Al alloy journal bearings reduce the friction coefficient by 28 % compared to the PTFE composites bearings. In addition, the Al alloy journal bearing worked properly at the maximum load of ∼ 8,000 N without adhesion. However, the PTFE composite journal bearings exhibited strong adhesion at the loads ranging from 6300 to 8000 N. This suggests that the Al alloy is a more promising material in journal bearings than PTFE composites.

Similar content being viewed by others

References

Z. Z. Zhang, Q. J. Xue, W. M. Liu and W. C. Shen, Tribological properties of metal-plastic multilayer composites under oil lubricated conditions, Wear 210 (1997) 195–203.

Z. Z. Zhang, Q. J. Xue, W. M. Liu and W. C. Shen, Friction and wear properties of metal powder filled PTFE composites under oil lubricated conditions, Wear 210 (1997) 151–156.

Y. Wan, Q. Xue and W. Liu, Tribological behavior of lubricating oil additives in lubricated aluminum-on-steel contact, Wear 196 (1996) 87–91.

H. Zhou, J. Chen and J. Jia, Investigation of the tribological behavior of an aluminum alloy with embedded materials, Materials Science and Engineering, A302 (2001) 222–226.

Z. Mu, F. Zhoua, S. Zhangb, Y. Lianga and W. Liua, Effect of the functional groups in ionic liquid molecules on the friction and wear behavior of aluminum alloy in lubricated aluminum-on-steel contact, Tribology International, 38 (2005) 725–731.

K. Lepper, M. James, J. Chashechkina and D.A. Rigney, Sliding behavior of selected aluminum alloys, Wear 203-204 (1997) 46–56.

C. F. Tu and T. Fort, A study of fiber-capstan friction. 1. Stribeck curves, Tribology International, 37 (2004) 701–710.

B. J. Hamrock, S. R. Schmid and B. O. Jacobson, Fundamentals of fluid film lubrication, Marcel dekker Inc., USA (2004) 9.

G. W. Stachowiak and A. W. Batchelor, Engineering Tribology, Elsevier Butterworth Heinemann, USA (2005) 152.

M. M. Maru and D. K. Tanaka, Consideration of Stribeck Diagram Parameters in the Investigation on Wear and Friction Behavior in Lubricated Sliding, J. of the Braz. Soc. of Mech. Sci. & Eng., 29(1) (2007) 55–62.

E. Durak, Experimental investigation of porous bearings under different lubricant and lubricating conditions, KSME Int. J., 9 (2003) 1276–1286.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor In-Ha Sung

Soo Hyung Kim received his B.S. degree from Pusan National University, M.S. degree from Gwangju Institute of Science and Technology, and Ph.D. degree from University of Minnesota. He is currently an Assistant Professor in the Department of Nanosystem and Nanoprocess Engineering of Pusan National University in Korea. His research fields are synthesis and characterization of nanostructured materials and their applications into nanofluids-based energy systems.

Bon Cheol Ku received his B.S. and M.S. degree from Pusan National University, Korea in 1984 and 1998, respectively. He is currently a Ph.D. student of the department of mechanical engineering of Pusan National University, Korea. His research fields are tribology, compressor and cogeneration.

Rights and permissions

About this article

Cite this article

Ku, B., Park, Y., Sung, C. et al. Comparison of tribological characteristics between aluminum alloys and polytetrafluoroethylene composites journal bearings under mineral oil lubrication. J Mech Sci Technol 24, 1631–1635 (2010). https://doi.org/10.1007/s12206-010-0508-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-010-0508-z