Abstract

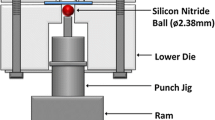

Compared with the conventional tensile creep test, it is much more difficult to obtain the creep properties of a material by the small punch creep test due to the complex deformation response and stress distribution in the miniature specimen of the material. Although creep behavior has been investigated by the small punch test, most studies have been limited to a specimen geometry and therefore, cannot be extended to other conditions conveniently. In this study, a new developed analysis routine is presented to derive the creep parameters of a material using data obtained from the small punch creep test. With the aid of the finite element method, the displacement and the displacement rate of the small punch are obtained for different load levels. The relationship between the stress and creep strain of the specimen and the applied load and the punch displacement is obtained by a dimensional analysis and the membrane stretching model. The creep properties obtained from small punch tests and the conventional creep tests are also compared. The values of the creep properties between the two types of tests agree well with each other within an acceptable accuracy range. This indicates that it is possible to obtain the creep parameters of a material from the small punch creep test instead of the conventional creep test by the analysis routines proposed in this study. Some suggestions for data reduction of the small punch creep tests are also presented to obtain more accurate material creep parameters.

Similar content being viewed by others

References

M. P. Manahan, A. S. Argon and O. K. Harling, The development of a miniaturized disk bend test for the determination of post-irradiation mechanical properties, Journal of Nuclear Materials. 104 (1981) 1545–1550.

J. H. Bulloch, The small punch toughness test: some detailed fractographic information. International Journal of Pressure Vessels and Piping. 63 (1995) 177–194.

A. A. Becker, T. H. Hyde and L. Xia, Numerical analysis of creep in components. The Journal of Strain Analysis for Engineering Design. 29 (1994) 185–192.

D. P. Butt, D. A. Korzekwa and S. A. Maloy, etc. Impression creep behavior of SiC particle-MoSi2 composites. Journal of Materials Research. 11 (1996) 1528–1536.

T. H. Hyde, K. A. Yehia and A. A. Becker, Interpretation of impression creep data using a reference stress approach. International Journal of Mechanical Sciences. 35(6) (1993) 451–462.

Z. Yang and Z. W. Wang, Relationship between strain and central deflection in small punch creep specimens. International Journal of Pressure Vessels and Piping. 80 (2003) 397–404.

K. B. Yoon, T. G. Park and S. H. Shim etc. Assessment of creep properties of 9Cr steel using small punch creep testing, Transaction of KSME(A) (in Korean). 25 (2001) 1493–1500.

T. G. Park, S. H. Shim and K. B. Yoon etc. A study on parameters measured during small punch creep testing. Transaction of KSME(A) (in Korean). 26 (2002) 171–178.

K. Milièka and F. Dobeš, Small punch testing of P91 steel. International Journal of Pressure Vessels and Piping. 83(9) (2006) 625–634.

R. Hurst, V. Bicego and J. Foulds, Small punch testing for creep — progress in Europe. Eighth International Conference on Creep and Fatigue at Elevated Temperatures. San Antonio, Texas. (2007) 1–6.

G. I. Barenblatt, Scaling, Self-Similarity, and Intermediate Asymptotics. Cambridge University Press, Cambridge. (1996).

Y. T. Cheng and C. M. Cheng, What is indentation hardness? Surface and Coatings Technology. 133–134 (2000) 417–424.

Y. J. Liu, B. Zhao, B. X. Xu and Z. F. Yue, Experimental and numerical study of the method to determine the creep parameters from the indentation creep testing. Materials Science and Engineering A. 456(1–2) (2007) 103–108.

Y. Cao, Determination of the creep exponent of a powerlaw creep solid using indentation tests. Mechanics of Time-Dependent Materials. 11(2) (2007) 159–172.

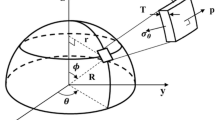

J. Chakrabarty, A theory of stretch forming over hemispherical punch heads. International Journal of Mechanical Sciences. 12 (1970) 315–325.

ABAQUS standard User’s Manual, Version 6.5, USA ABAQUS Inc. (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Youngseog Lee

Jian Jun Chen received his Ph. D. degree in Mechanical Engineering from East China University of Science and Technology, China, in 2008. Dr. Chen is currently a Post Doctor at the School of Mechanical Engineering of Chung-Ang University in Seoul, Korea. His research interests are mainly in the material’s high temperature behavior, the creep properties obtained by the non-standard specimen and the interaction between creep and fatigue.

Young Wha Ma received his Ph. D. degree in Mechanical Engineering from Chung-Ang University, Korea in 2007. After that, he worked at Georgia Institute of Technology, U.S.A. as a postdoc. Dr. Ma is currently a research professor at Mechanical Engineering of Chung-Ang University in Seoul, Korea. His interest is mainly in application of high temperature fracture mechanics to residual life assessment of structural materials including anisotropic materials such as gas turbine blade.

Kee Bong Yoon has conducted various researches in the field of high temperature fracture mechanics including creep and creep-fatigue crack growth behavior of structural materials. He has further interest in application such as residual life assessment of power plant components and risk based maintenance approaches. After 10 year experiences in a national research institute he moved to the mechanical engineering department in Chung Ang University. He received his B.E. and M.S from Seoul National University and KAIST respectively and he got Ph.D. degree from Georgia Tech in U.S.A. Currently he is the research dean of the University.

Rights and permissions

About this article

Cite this article

Chen, J., Ma, Y.W. & Yoon, K.B. Finite element study for determination of material’s creep parameters from small punch test. J Mech Sci Technol 24, 1195–1201 (2010). https://doi.org/10.1007/s12206-010-0327-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-010-0327-2