Abstract

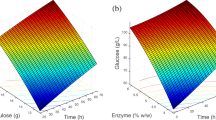

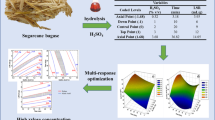

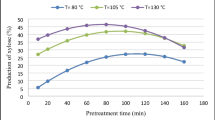

Based on a five level central composite design (CCD) involving the variables substrate concentration (C), pH (P), incubation temperature (T) and fermentation time (H), a response surface methodology (RSM) for the production of ethanol from pretreated sugarcane bagasse by cellulase and yeast Kluyveromyces fragilis was standardized. The design contains a total of 31 experimental trials in which the first 24 organized in a factorial design and from 25 to 31 involving the replications of the central points. Data obtained from RSM on ethanol production were subjected to the analysis of variance (ANOVA) and analyzed using a second order polynomial equation. Maximum ethanol concentration (32.6 g/l) was obtained from 180 g/l pretreated sugarcane bagasse at the optimized process conditions (temperature 35°C, pH 5.5) in 72 h aerobic batch fermentation. Various kinetic models such as logistic model, logistic incorporated leudeking piret model and logistic incorporated modified leudeking piret model have been evaluated and the constants were predicted.

Similar content being viewed by others

References

Adsul MG, Ghule JE, Shaikh H, Singh R, Bastawde KB, Gokhale DV, Varma AJ et al (2005) Enzymatic hydrolysis of delignified bagasse polysaccharides. Carbohy Poly 62:6–10

Aiba S (1973) Biochemical engineering: comprehensive text on fermentation treats batch kinetics. In: Aiba S (ed) Biochemical engineering. 2nd edn. Academic, New York

Anderson PJ, Neil Mc K, Watson C et al (1986) High efficiency carbohydrate fermentation to ethanol at temperatures above 40°C by Kluyveromyces marxianus var. marxianus isolated form sugar mills. Appl Env Microbio 51:1314–1320

Bailey JE (1986) Kinetics of substrate utilization, product formation and biomass production in cell cultures. In: Bailey JE (ed) Biochemical engineering fundamentals. 3rd edn. McGraw Hill, New York

Balat M, Balat H, Cahide Z et al (2007) Progress in bioethanol processing. Prog Energ Combus Sci 12:137–145

Ballesteros M, Oliva JM, Ballesteros I et al (1993) Optimization of the simultaneous saccharification and fermentation process using thermotolerant yeasts. Appl Biochem Biotechnol 40:201–211

Ballesteros M, Oliva JM, Negro MJ, Manzanares P, Ballesteros I et al (2004) Ethanol from lignocellulosic materials by a simultaneous saccharification and fermentation process with Kluyveromyces marxianus. Proc Biochem 391:1843–1848

Balusu R, Paduru RR, Kuravi SK, Seenaya G, Reddy G et al (2005) Optimization of critical medium components using response surface methodology for ethanol production from cellulosic biomass by Clostridium thermocellum SS19. Proc Biochem 40:3025–3030

Bas D, Ismail H, Boyaci J et al (2007) Modeling and optimization I: usability of response surface methodology. J Food Eng 78:836–845

Blakebrough N (1967) A useful reference for several aspects of biological reactor design and fermentation process kinetics. In: Blakebrough N (ed) Biochemical and biological engineering science. 1st edn. Academic, New York

Cardona CA, Sanchez OJ (2007) Fuel ethanol production: process design trends and integration opportunities. Bioresour Technol 98:2415–2457

Dawson L, Boopathy R (2007) Use of post harvest sugarcane residue for ethanol production. Bioresour Technol 98:1695–1699

Deindoerfer FH (1960) Fermentation kinetics and model processes. Adv Appl Microbiol 2:321–327

Fredrickson AG, Megee RD, Tsuchiya HM et al (1970) Mathematical models for fermentation processes. Adv Appl Microbiol 23:419–425

Giovanni M (1983) Response surface methodology and product optimization. J Food Technol 37:41–45

Han K, Levenspiel O (1988) Extended Monod kinetics for substrate, product and cell inhibition. Biotechnol Bioeng 32:430–437

Himmel ME, Ruth MF, Wyman CE et al (1999) Production of bioethanol from lignocellulosic materials. Curr Opin Biotechnol 10(4):358–364

Kaar WE, Gutierrez CV, Kinoshita CM et al (1998) Steam explosion of sugarcane bagasse as a pretreatment for conversion to ethanol. Biomass Bioenerg 14(3):277–287

Kalil SJ, Maugeri F, Rodrigues MI et al (2000) Response surface analysis and simulation as a tool for bioprocess design and optimization. Proc Biochem 35:539–550

Kim S, Dale BE (2004) Global potential bioethanol production from wasted crops and crop residues. Biomass Bioenerg 26:361–375

Laser M, Schulman D, Allen SG, Lichwa J, Antal MJ, Lynd LR et al (2002) A comparison of liquid hot water and steam pretreatments of sugar cane bagasse for bioconversion to ethanol. Bioresour Technol 81:33–44

Leudeking R, Piret EL (1959) A kinetic study of the lactic acid fermentation. J Biochem Microbiol Technol Eng 1:393–400

Lin Y, Tanaka S (2006) Ethanol fermentation from biomass resources: current state and prospects. Appl Microbiol Biotechnol 69:627–642

Lynd LR, Elander RT, Wyman CE et al (1996) Evaluation of paper sludge for amenability to enzymatic hydrolysis and conversion to ethanol. Appl Biochem Biotechnol 57/58:741–761

Mandel M, Andreotti R, Roche C et al (1976) Measurement of saccharifying cellulase. Biotechnol Bioeng Symp 6:21–33

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of total reducing sugar. Anal Chem 31:420–426

Morjanoff PJ, Gray PP (1987) Optimization of steam explosion as a method for increasing susceptibility of sugarcane bagasse to enzymatic saccharification. Biotechnol Bioeng 24:733–741

Okpokwasili GC, Nweke CO (2005) Microbial growth and substrate utilization. African J Biotechnol 5(4):305–317

Pala H, Mota M, Miguel Gama F et al (2007) Enzymatic depolymerization of cellulose. Carbohy Poly 68:101–108

Pandey A, Soccol CR, Nigam P, Soccol VT et al (2000) Biotechnological potential of agro-industrial residues. I: Sugarcane bagasse. Bioresour Technol 74:69–81

Philiphidis GP, Smith TK, Wyman CE et al (1993) Study of the enzymatic hydrolysis of cellulose for production of fuel ethanol by the simultaneous Saccharification and fermentation process. Biotechnol Bioeng 41:846–853

Chandrakant P, Bisaria VS (1998) Simultaneous bioconversion of cellulose and hemicellulose to ethanol. Critic Rev Biotechnol 18(4):295–331

Roels JA (1983) An excellent integrated treatment of macroscopic thermodynamics and kinetic models for microbial growth and product formation. In: Roels JA (ed) Energetics and kinetics in biotechnology. 2nd edn. Elsevier, Amsterdam

Sanjay KR, Kumaresan N, Manohar B, Umeshkumar S, Vijayalakshmi G et al (2007) Optimization of carotenoid production by Aspergillus carbonarius in submerged fermentation using RSM. Inter J Food Eng 3(5):19–27

Szczodrak J, Targonski Z (1988) Selection of thermotolerant yeast strains for simultaneous saccharification and fermentation of cellulose. Biotechnol Bioeng 31:300–303

Tsao GT, Hanson TP (1975) Extended Monod equation for batch cultures with multiple exponential phases. Biotechnol Bioeng 17:1591–1598

Updegroff DM (1969) Estimation of cellulose by anthrone reagent. Anal Chem 32:420–423

Wyman CE (1994) Ethanol from lignocellulosic biomass: technology economics, and opportunities. Bioresour Technol 50:3–15

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11

Acknowledgements

The authors express their sincere thanks to UGC for the financial support through the Rajiv Gandhi National Fellowship Scheme (RGNFS) for the fellowship to one of the authors (E. Sasikumar) and to the Department of Technology, Annamalai University for providing the necessary facilities for the successful completion of this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sasikumar, E., Viruthagiri, T. Optimization of Process Conditions Using Response Surface Methodology (RSM) for Ethanol Production from Pretreated Sugarcane Bagasse: Kinetics and Modeling. Bioenerg. Res. 1, 239–247 (2008). https://doi.org/10.1007/s12155-008-9018-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-008-9018-6