Abstract

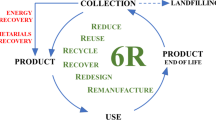

In this study, recycled polymer feedstocks (high-density polyethylene, HDPE and polypropylene, PP) were added with different percentages of activated carbon (AC) made from coconut fiber waste – 0, 2, 4, 6, and 8%. The melting temperatures of the recycled HDPE and HDPE/PP filaments were 113 and 170°C, respectively. The addition of AC improved the thermal stability of the recycled filaments up to 28% while decreased the crystallinity of the filament produced, resulting in a more uniform surface with less crazing. Incompatibility of the recycled HDPE and AC was observed. However, the presence of PP greatly enhanced the compatibility of AC with the HDPE polymer. With the addition of 8% AC to the recycled HDPE/PP, the elongation at break of the recycled HDPE/PP filament reached 54.2%, about 10 times higher than that without AC, which could be due to the passive local interfacial bonding of AC with the methyl group of the PP matrix. The improved elongation at break would in turn aid in 3D printing of products with better elasticity.

Similar content being viewed by others

References

Chong S, Chiu H-L, Liao Y-C, Hung S-T and Pan G-T 2015 Cradle to Cradle® Design for 3D Printing. Chem. Eng. Trans. 45: 1669–1674

Kreiger M A, Mulder M L, Glover A G and Pearce J M 2014 Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament. J. Clean. Prod. 70: 90–96

Chong S, Pan G-T, Khalid M, Yang T C-K, Hung S-T and Huang C-M 2017 Physical characterization and pre-assessment of recycled high-density polyethylene as 3D printing material. J. Polym. Environ. 25(2): 136–145

Tokoro R, Vu D M, Okubo K, Tanaka T, Fujii T and Fujiura T 2008 How to improve mechanical properties of polylactic acid with bamboo fibers. J. Mater. Sci. 43(2): 775–787

Murphy C A and Collins M N 2018 Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym. Compos. 39(4): 1311–1320

ders 2013 Wood filament LAYWOO-D3 suppliers and price compare. [2016/10/24]; Available from: http://www.3ders.org/articles/20130204-wood-filament-laywoo-d3-suppliers-and-price-compare.html

Okada A and Usuki A 2006 Twenty years of polymer-clay nanocomposites. Macromol. Mater. Eng. 291(12): 1449–1476

Coleman J N, Khan U, Blau W J and Gun’ko Y K 2006 Small but strong: a review of the mechanical properties of carbon nanotube–polymer composites. Carbon. 44(9): 1624–1652

Fasolino A, Los J and Katsnelson M I 2007 Intrinsic ripples in graphene. Nat. Mater. 6(11): 858

Refil 2020 [2017/04/10]. Available from: http://www.re-filament.com/

MakerGeeks 2019 [2015/03/05]. Available from: http://www.makergeeks.com/

Fim F C, Guterres J M, Basso N R and Galland G B 2010 Polyethylene/graphite nanocomposites obtained by in situ polymerization. J. Polym. Sci. A Polym. Chem. 48(3): 692–698

Dalton E and Collins M N 2014 Lamella alignment ratio: a SAXS analysis technique for macromolecules. J. Appl. Crystallogr. 47(3): 847–851

Pan G T, Chong S, Tsai H J, Lu W H and Yang T C K 2018 The effects of iron, silicon, chromium, and aluminum additions on the physical and mechanical properties of recycled 3D printing filaments. Adv. Polym. Technol. 37(4): 1176–1184

Launer P J 2013 Infrared analysis of organosilicon compounds: spectra-structure correlations. Reprinted from Silicone Compounds: Silanes & Silicones. [2016/10/30]. Available from: https://www.gelest.com/wp-content/uploads/5000A_Section1_InfraredAnalysis.pdf

Ultimaker 2016 Ultimaker Materials. [2016/10/30]. Available from: https://ultimaker.com/en/products/materials

Iqbal J, Pandey K, Verma V, Singh P and Mishra R 2015 Physico-mechanical and thermal behaviour of binary blends of EPDM and LLDPE. European J. Adv. Eng. Technol. 2(10): 43–48

Bagheri S and Julkapli N M 2016 Effect of hybridization on the value-added activated carbon materials. Int. J. Ind. Chem. 7(3): 249–264

Xiao Q and Zhou X 2003 The study of multiwalled carbon nanotube deposited with conducting polymer for supercapacitor. Electrochim. Acta. 48(5): 575–580

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chong, S., Yang, T.CK., Lee, KC. et al. Evaluation of the physico-mechanical properties of activated-carbon enhanced recycled polyethylene/polypropylene 3D printing filament. Sādhanā 45, 57 (2020). https://doi.org/10.1007/s12046-020-1294-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-020-1294-7