Abstract

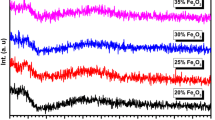

Lithium phosphate glasses with the basic composition (\({\hbox {P}}_{2} {\hbox {O}}_{5}\) 50 and \({\hbox {Li}}_{2} \hbox {O}\) 50 mol%) series by the addition of copper oxide (0, 10, 15 and 20 g/100 g) were prepared by a melt quenching technique. Fourier-transform infrared (FTIR) absorption spectra and X-ray diffraction (XRD) analysis were used to characterize the glass samples. Thermal expansion and mass density were also measured. The different mechanical properties of the prepared glasses were measured by an ultrasonic non-destructive technique. Additionally, both frequency and temperature dependence of alternating-current conductivity were measured in the frequency range of 40 Hz–1 MHz and the temperature range of 308–488 K. Moreover, direct current conductivity was also measured for the same temperature range. FTIR measurements confirm the appearance of the bands of phosphate groups and the assumption of bonds formed between Cu and P. XRD spectra approve the amorphous nature of the studied glasses. Thermal expansion and mass density of the prepared samples show an increase in values by increasing the CuO content. The mechanical properties of the studied glasses (hardness (\(H_{\mathrm{v}}\)), Young’s modulus (E), elastic modulus (L), bulk modulus (K), shear modulus (G) and Poisson’s ratio (\(\nu \))) were positively affected by the CuO content, reflecting a better packed structure. Furthermore, the electrical conductivity values of the prepared glasses are identified to increase with an increase in both temperature and CuO content. Such trends agree with the data obtained by thermal expansion and FTIR. The progressive addition of CuO is assumed to improve thermal, mechanical and electrical properties of the prepared lithium phosphate glasses.

Similar content being viewed by others

References

Youness R A, Taha M A, El-Kheshen A A, El-Faramawy N and Ibrahim M A 2019 Mater. Res. Express 6 075212

ElBatal H, ElMandouh Z, Zayed H, Marzouk S, Elkomy G and Hosny A 2013 J. Mol. Struct. 57 1054

Dai S, Sugiyama A, Hu L, Liu Z, Huang G and Jiang Z 2002 Non-Cryst. Solids 311 138

Sharaf El-Deen L M, Al Salhi M S and Elkholy M M 2008 Non-Cryst. Solids 354 5453

Cozar O, Magdas D A and Ardelean I 2008 Non-Cryst. Solids 354 1032

Metwalli E 2003 Non-Cryst. Solids 317 221

Elbatal F H 2008 Mater. Sci. 43 1070

Seydei M K P and Suthanthiraraj S A 1996 Solid State Ion 86 459

Mugoni C, Montorsi M, Siligardi C and Jain H 2014 Non-Cryst. Solids 387 137

Jozwiak P and Garbarczyk J E 2005 Solid State Ion. 176 2163

Saienga J and Martin S W 2008 Non-Cryst. Solids 354 1475

Kolar J, Wagner T, Zima V, Stehlik S, Frumarova B, Benes L, et al 2011 Non-Cryst. Solids 357 2223

Jlassi I, Sdiri N and Elhouichet H 2017 Non-Cryst. Solids 466–467 45

Rioux M, Ledemi Y and Messaddeq Y 2017 Non-Cryst. Solids 459 169

Palui A and Ghosh A 2018 Non-Cryst. Solids 482 230

Langar A, Sdiri N, Elhouichet H and Ferid M 2017 Results Phys. 7 1022

Aboulfotoha N, Elbasharb Y, Ibrahem M and Elokr M 2014 Ceram. Int. 7 10395

Youness R A, Taha M A, Elhaes H and Ibrahim M 2017 Mater. Chem. Phys. 190 209

Youness R A, Taha M A and Ibrahim M A 2017 J. Mol. Struct. 1150 188

Zawrah M F, Taha M A and Abo Mostafa H 2018 Ceram. Int. 44 10693

Youness R A, Taha M A and Ibrahim M A 2018 Ceram. Int. 44 21323

Youness R A, Taha M A, El-Kheshen A A and Ibrahim M A 2018 Ceram. Int. 44 20677

Abo-Naf S M, El-Amiry M S and Abdel-Khalek A A 2008 Opt. Mater. 30 900

Radhakrishnan A A and Beena B B 2014 Indian Adv. Chem. Sci. 2 158

Abdelghany A M, ElBatal H A and Marei L K 2012 Radia. Eff. Defects Solids 167 49

Khalil E M A, ElBatal F H, Hamdy Y M, Zidan M H, Aziz M S and Abdelghany A M 2010 J. Physica B 405 1294

El Batal H A, Abdelghany A M and Ali I S 2012 J. Non-Cryst. Solids 358 820

Marzouk S Y 2009 Mater. Chem. Phys. 114 188

Chahine A, Et-tabirou M, Elbenaissi M, Haddad M and Pascal J L 2004 Mater. Chem. Phys. 84 341

Nabhan E, Nabhan A and Abd El Aal N 2016 Am. J. Phys. Appl. 4 145

Ouis M A, Azooz M A and ElBatal H A 2018 Non-Cryst. Solids 494 31

Ouis M A, ElBatal H A, Abdelghany A M and Hammad A H 2016 J. Mol. Struct. 1103 224

Soheyli E and Hekmatshoar M H 2014 Phys. Scr. 89 075801

Halder A, Mandal B, Mahanty S, Sen R and Mandal A K 2017 Bull. Mater. Sci. 40 999

Mugoni C, Montorsi M, Siligardi C and Jain H 2014 Non-Cryst. Solids 383 137

Shih P Y, Yung S W and Chin T S 1998 Non-Cryst. Solids 224 143

Shih P Y, Yung S W and Chin T S 1999 Non-Cryst. Solids 244 211

Baino F 2018 Ceram. Int. 13 14953

Choudhary B P, Rai S and Singh N B 2016 Ceram. Int. 42 10813

Choudhary B P 2017 Mater. Today: Proc. 4 5706

Youness R A, Taha M A, Ibrahim M and El-Kheshen A 2018 Silicon 10 1151

Srivastava A K and Pyare R 2012 Int. J. Sci. Technol. 1 28

Rao G V and Shashikala H D 2014 Glass Phys. Chem. 40 303

Brogliaa G, Mugonib C, Siligardib C and Montorsi M 2018 Non-Cryst. Solids 481 522

Cho K I, Lee S H, Shin D W and Sun Y K 2006 Electrochim. Acta 52 1576

Swenson J and Borjesson L 1996 Phys. Rev. Lett. 77 3569

Milanković A M, Pavić L, Reis S T, Day D E and Ivanda M 2010 J. Non-Cryst. Solids 356 715

Khoon T F, Hassan J, Wahab Z A and Azis R S 2016 Results Phys. 19 2081

Murawski L, Chung C H and Mackenize J D 1979 J. Non-Cryst. Solids 32 91

Shapaan M, ElBadry S A, Mostafa A G, Hassaan M Y and Hazzaa M H 2012 Phys. Chem. Solids 73 407

Karmakar B, Rademann K and Stepanov A 2016 Ch.1 (Amsterdam 3: Elsevier B.V.) 3 53

Muralidharan P, Satyanarayana N and Venkateswarlu M 2005 Phys. Chem. Glasses 46 293

Farid A M and Bekheet A E 2000 Vacuum 59 932

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ouis, M.A., Taha, M.A., El-Bassyouni, G.T. et al. Thermal, mechanical and electrical properties of lithium phosphate glasses doped with copper oxide. Bull Mater Sci 42, 246 (2019). https://doi.org/10.1007/s12034-019-1897-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-019-1897-y