Abstract

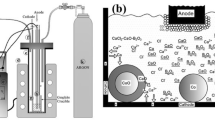

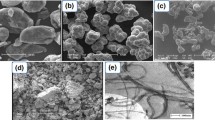

Cobalt boride (Co2B) is a significant transition metal boride having a wide range of usage area due to its high oxidation, abrasion and corrosion resistance as well as its superior electrochemical, magnetic and anisotropic properties. In this study, pure Co2B nanocrystals were synthesized with Co, B2O3 and Mg as starting materials via the mechanochemical synthesis (MCS) method by high-energy planetary ball mill in a hardened steel vial with hardened steel balls. All the experiments were conducted under Ar atmosphere at different rotational speeds and at 20 : 1–30 : 1–40 : 1 ball-to-powder ratios. Leaching of Co2B + MgO powder mixtures occurred after milling and purified with acetic acid and pure Co2B nanocrystals were obtained in solid form. The Co2Bs were characterized through X-ray diffraction, scanning electron microscopy, vibrating sample magnetometer, Brunauer–Emmett–Teller and specific density analyses, and effects of synthesis parameters on product properties were revealed. Surface areas of the powders synthesized at 40 : 1 ball-to-powder ratio at different rotational speeds were measured as 21.14, 40.36 and 52.33 m2 g−1, respectively. Crystallite sizes of Co2B nanocrystals were between 7.27 and 9.84 nm and their specific density varied between 7.61 and 7.78 g cm−3. It was determined that all samples were saturated and exhibited hysteresis and ferromagnetic behaviours, and saturation magnetization was between 35 and 50 emu g−1.

Similar content being viewed by others

References

Pratt J M and Swinden G 1969 J. Chem. Soc. D 22 1321

Maybury P C, Mitchell R W and Hawthorn M F 1974 J. Chem. Soc.: Chem. Commun. 14 534

Nitta Y, Imanaka T and Teranishi S 1980 Bull. Chem. Soc. Jpn. 53 3154

Chen Y Z and Wu K J 1991 Appl. Catal. 78 185

Glavee G N, Klabunde K J, Sorensen C M and Hadjapanayis G C 1993 Langmuir 9 162

Petit C and Pileni M P 1997 J. Magn. Magn. Mater. 166 82

Ma H Y, Li G Z, Zhang J P, Shen Q and Wang X 1998 J. Dispers. Sci. Technol. 19 511

Wu C, Wu F, Bai Y, Yi B and Zhang H 2005 Mater. Lett. 59 1748

Liu B H, Li Z P and Suda S 2006 J. Alloys Compd. 415 288

Jeong S U, Cho E A, Nam S W, Oh I H, Jung U H and Kim S H 2007 Int. J. Hydrogen Energy 32 1749

Ingersoll J C, Mani N, Thenmozhiyal J C and Muthaiah A 2007 J. Power Sources 173 450

Walter J C, Andrew Z, Daniel M, Thornburg M and Revankar S 2008 J. Power Sources 179 335

Liu B H and Li Q 2008 Int. J. Hydrogen Energy 33 7385

Wang Y P, Wang Y J, Ren Q L, Li L, Jiao L F, Song D W, Liu G et al 2010, Fuel Cells 10 132

Hongjing T, Qingjie G and Dongyan X 2010 J. Power Sources 195 2136

Chuan W, Ying B, Dan-Xian L, Wu F, Pang M L and Yi B L 2011 Catal. Today 170 33

Ozerova A M, Bulavchenko O A, Komova O V, Netskina O V, Zaikovskii V I, Odegova G V et al 2012, Kinet. Catal. 53 511

Kanomata T, Ise Y, Kumagai N, Haga A, Kamishima K, Goto T, Kimura H M et al 1997, J. Alloys Compd. 259 L1

Choi S, Lapitan L D S, Cheng Y and Watanabe T 2014 Adv. Powder Technol. 25 365

Iizumi K, Kudaka K, Maezawa D and Sasaki T 1999 J. Ceram. Soc. Jpn. 107 491

Welham N J 2000 J. Am. Ceram. Soc. 83 1290

Kudaka K, Iizumi K, Sasaki T and Okada S 2001 J. Alloys Compd. 315 104

Kudaka K, Iizumi K, Izumi H and Sasaki T 2001 J. Mater. Sci. Lett. 20 1619

Iizumi K, Sekiya C, Okadac S, Kudou K and Shishido T 2006 J. Eur. Ceram. Soc. 26 635

Kim J W, Shim J H, Ahn J P, Cho Y W, Kim J H and Oh K H 2008 Mater. Lett. 62 2461

Jiang X, Trunov M A, Schoenitz M, Dave R N and Dreizin E L 2009 J. Alloys Compd. 478 246

Akgün B, Çamurlu H E, Topkaya Y and Sevinç N 2011 Int. J. Refract. Met. Hard Mater. 29 601

Çamurlu H E 2011 J. Alloys Compd. 509 5431

Balcı O, Ağaoğulları D, Duman İ and Öveçoğlu M L 2012 Ceram. Int. 38 2201

Ağaoğulları D, Duman İ and Öveçoğlu M L 2012 Ceram. Int. 38 6203

Balcı Ö, Ağaoğulları D, Duman İ and Öveçoğlu M L 2012 Powder Technol. 225 136

Shao J, Xiao X, Fan X, Chen L, Zhu H, Yu S et al 2013, Mater. Lett. 109 203

Bahrami-Karkevandi M, Ebrahimi-Kahrizsangi R and Nasiri-Tabrizi B 2014 Int. J. Refract. Met. Hard Mater. 46 117

Torabi O, Naghibi S, Golabgir M H, Tajizadegan H and Jamshidi A 2015 Ceram. Int. 41 5362

Jafari M, Tajizadegan H, Golabgir M H, Chami A and Torabi O 2015 Int. J. Refract. Met. Hard Mater. 50 86

Torabi O, Ebrahimi-Kahrizsangi R, Golabgir M H, Tajizadegan H and Jamshidi A 2015 Int. J. Refract. Met. Hard Mater. 48 102

Wang Y D, Guang X Y and Mu P 2012 Chin. Sci. Bull. 57 4225

Suryanarayana C 2004 Mechanical alloying and milling (New York: Marcel Dekker)

Önder O 2009 Synthesis of lithium borides by mechanochemical process Master Thesis (Ankara: Middle East Technical University)

Can M M, Özcan Ş, Ceylan A and Fırat T 2010 Mater. Sci. Eng. B 172 72

Avar B and Özcan S 2015 J. Alloys Compd. 650 53

Şimşek T 2014 Investigation of the zirconium diboride nanocrystal coated different materials mechanic and mechinability properties PhD Thesis (Ankara: Gazi University)

Acknowledgement

We are very grateful to Eti Maden Works General Management for financial support and laboratory facilities usage.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

BARIS, M., SIMSEK, T. & AKKURT, A. Mechanochemical synthesis and characterization of pure Co2B nanocrystals. Bull Mater Sci 39, 1119–1126 (2016). https://doi.org/10.1007/s12034-016-1231-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-016-1231-x