Abstract

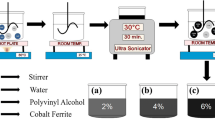

The objective of the present study was basic understanding of the formation of thin film morphology by spin coating using reorganized polyethylene terephthalate (r-PET) and multiwalled carbon nanotubes (MWCNTs) as fillers in PET. A study of the correlation between physical properties of the PET films and its surface morphology was carried out using atomic force microscopy-based power spectral density (PSD) analysis. No significant work of surface analysis, using PSD of thin films of PET has been reported till date. Dilute solution of PET, PET with 3 wt% (r-PET) and PET with 3 wt% (2 wt% r-PET + 1 wt% MWCNT) filler were prepared using trifluoroacetic acid (TFA) as a solvent and thin films were fabricated on glass substrate by the optimized spin coating technique. Preparation of r-PET and r-PET + MWCNT fillers was obtained by the precipitation method using TFA as a solvent and acetone as an antisolvent. The samples before spin coating were extruded and for comparison, a film of non-extruded PET was also prepared. Structural studies by Fourier transform infrared and X-ray diffraction show higher degree of crystallinity in r-PET and decrease in chain entanglements. Owing to the crystallizing behaviour of r-PET, it allows better dispersion of MWCNT in the polymer matrix as compared with PET. The samples with fillers of MWCNT show more compact and unique mesh-like globular structure, indicating application for electromagnetic shielding foams and fibres.

Similar content being viewed by others

References

Lijima S 1991 Nature 354 56

Moniruzzaman M and Winey K I 2006 Macromolecules 39 5194

Gupta S J, Prabhu P, Singh A, Sreeram B, Dhulia V, Yadav B S and Kanwar A 2009 J. Mol. Cryst. Liquid Cryst. 511 1545

Deshpande V D and Jape S 2009 J. Appl. Polym. Sci. 111 1318

Murthy N S, Zero K and Minor H 1994 Macromolecules 27 1484

Lin S B and Koenig J L 1982 J. Polym. Sci.: Polym. Phys. Ed. 20 2277

Lin S B and Koenig J L 1984 J. Polym. Sci.: Polym. Symp. 71 121

Oromiehie A and Mamizadeh A 2004 Polym. Int. 53 728

Hu G, Feng X, Zhang S and Yang M 2008 J. Appl. Polym. Sci. 108 4080

Hsiao A-E, Tsai S-Y, Hsu M-W and Chang S-J 2012, Nanoscale Res. Lett. 7 240

Mallakpour S and Zadehnazari A 2014 Bull. Mater. Sci. 37 1065

Song J, Liang J, Liu X, Krause W E, Hinestroza J P and Rojas O J 2009 Thin Solid Films 517 4348

Mazinani S, Ajji A and Dubois C 2010 J. Polym. Sci.: Part B: Polym. Phys. 48 2052

Xianwen R, Weng L T, Chan C-M and Ng K-M 2013, Surf. Interface Anal. 45 1291

Vedula J and Tonelli A E 2006 J. Polym. Sci.: Part B 45 735

Singh A R and Deshpande V D 2013 AIP Conf. Proc. 1538 190

Ubale A U, Sakhare Y S, Bhute M V, Belkhedkar M R and Singh A 2013 Solid State Sci. 16 134e142

Schmidt R H, Kinloch I A, Burgess A N and Windle A H 2007 Langmuir 23 5707

Prasad S G, De A and De U 2011 Int. J. Spectrosc. 2011 Article ID 810936

Cole K C, Guevremont J, Ajji A and Dumoulin M M 1994 Appl. Spectrosc. 48 1513

Bullions T A, Wei M, Porbeni F E, Gerber M J, Peet J, Balik M, White J L and Tonelli A 2002 J. Polym. Sci.: Part B: Polym. Phys. 40 992

Ilišković N and Bravar M 1986 Polym. Degrad. Stabil. 15 173

Renyuan Q, Deyan S and Fuge Sun 1996 Macromol. Chem. Phys. 197 1485

Dhall S and Jaggi N 2014 Bull. Mater. Sci. 37 1427

Barbadikar D, Gautam R, Sahare S, Patrikar R and Bhatt J 2013 Bull. Mater. Sci. 36 483

Santhilkumar N, Sahoo N K, Thakur S and Tokas R B 2005 Appl. Surf. Sci. 252 1608

Manvi G, Singh A, Jagtap R N and Kothari D C 2012 Prog. Org. Coat. 75 139

Ferreira Q, Bernardo G, Charas A, Alcácer L and Morgado J 2010 J. Phys. Chem. C 114 572

Xu Y, Jia H-B, Piao J-N, Ye S-R and Huang J 2008 J. Mater. Sci. 43 417

Acknowledgements

We are thankful to UGC for providing UGC-SAP Fellowship and UGC major Research project (F No. 41-881/2012 (SR)).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

SINGH, A.R., DESHPANDE, V.D. Processing and characterization of extruded PET and its r-PET and MWCNT nanocomposite thin films by spin coating. Bull Mater Sci 39, 167–175 (2016). https://doi.org/10.1007/s12034-015-1116-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-1116-4