Abstract

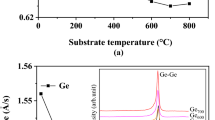

Si quantum dots-based structures are studied recently for performance enhancement in electronic devices. This paper presents an attempt to get high density quantum dots (QDs) by low pressure chemical vapour deposition (LPCVD) on SiO 2 substrate. Surface treatment, annealing and rapid thermal processing (RTP) are performed to study their effect on size and density of QDs. The samples are also studied using Fourier transformation infrared spectroscopy (FTIR), atomic force microscopy (AFM), scanning electron microscopy (SEM) and photoluminescence study (PL). The influence of Si–OH bonds formed due to surface treatment on the density of QDs is discussed. Present study also discusses the influence of surface treatment and annealing on QD formation.

Similar content being viewed by others

References

Adachi M M 2007 Low temperature thin film silicon solar cells prepared by hot wire chemical vapour deposition, Master of Applied Sciences, Simon Fraser University, Canada

Fauchet P M 1996 J. Lumin. 70 294

Geller M, Marent A, Nowozin T, Feise D, Potschke K, Akcay N, Oncan N and Bimberg D 2008 Physica E 40 1811

Gencer Imer A, Yerci S, Alagoz A S, Kulakci M, Serincan U, Finstad T G and Turan R 2010 J. Nanosci. Nanotechnol. 10 525

Grundmann M et al 1998 Thin Solid Films 318 83

Knoss R W 2009 Quantum dots: Research technology and applications (New York: Nova Science Publishers Inc.) ch. 1, p. 1

Makihara K, Deki H, Murakami H, Higashi S and Miyazaki S 2005 Appl. Surf. Sci. 244 75

Matsumura 1986 Jpn. J. Appl. Phys. 25 L949

Mazen F, Baron T, Bremond G, Buffet N, Rochat N, Mur P and Semeria M N 2003 J. Electrochem. Soc. 150 G203

Mercaldo L V, Veneri P D, Emilia Esposito, Ettore Massera, Iurie Usatii and Carlo Privato 2009 Mater. Sci. Eng. B159–160 77

Mestanza, Obrador S N M, Rodriguez M P, Biasotto E, Doi C, Diniz I and Swart J A 2006 J. Vac. Sci. Technol. B24 823

Miyazaki S, Hamamoto Y, Yoshida E, Ikeda M and Hirose M 2000 Thin Solid Films 369 55

Pant A and Russell T W F 2001 Ind. Eng. Chem. Res. 40 1377

Qin G G and Jia Y Q 1993 Solid State Commun. 86 559

Soon J O, Yook K S, Joo C W and Lee J Y 2009 J. Ind. Eng. Chem. 15 602

Suquet H 1989 Clays Clay Miner. 37 439

Wiesmann H, Ghosh A K, McMahon T and Strongin M 1979 J. Appl. Phys. 50 3752

Zhao Zhouying, Arrandale Mayrita, Vassiltsova Oxana V, Marina A and Carpenter Michael A 2009 Sens. Actuators B141 26

Acknowledgements

Authors are thankful to Ministry of Communication and Information Technology, Government of India, for funding and INUP, Indian Institute of Technology, Bombay, for supporting this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

BARBADIKAR, D., GAUTAM, R., SAHARE, S. et al. Optimization of process parameter for synthesis of silicon quantum dots using low pressure chemical vapour deposition. Bull Mater Sci 36, 483–490 (2013). https://doi.org/10.1007/s12034-013-0487-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-013-0487-7