Abstract

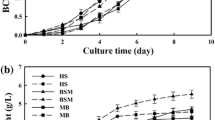

Bio-cellulose is the microbial extracellular cellulose that is produced by growing several microorganisms on agriculture by-products, and it is used in several food applications. This study aims to utilize sago by-product, coconut water, and the standard medium Hestrin-Schramm as the carbon sources in the culture medium for bio-cellulose production. The bacteria Beijerinkia fluminensis WAUPM53 and Gluconacetobacter xylinus 0416 were selected based on their bio-cellulose production activity. The structure was determined by Fourier transform infrared spectroscopy and scanning electron microscopy, while the toxicity safety was evaluated by brine shrimp lethality test. The results of Fourier transform infrared spectroscopy showed that the bio-cellulose produced by B. fluminensis cultivated in sago by-products was of high quality. The bio-cellulose production by B. fluminensis in the sago by-product medium was slightly higher than that in the coconut water medium and was comparable with the production in the Hestrin-Schramm medium. Brine shrimp lethality test confirmed that the bio-cellulose produced by B. fluminensis in the sago by-product medium has no toxicity, which is safe for applications in the food industry. This is the first study to determine the high potential of sago by-product to be used as a new carbon source for the bio-cellulose production.

Similar content being viewed by others

References

Keshk, S. M. A. S. (2014). Bacterial cellulose production and its industrial applications. Journal of Bioprocessing and Biotechniques, 4, 150–159.

Carreira, P., Mendes, J. A. S., Trovatti, E., Serafim, L. S., Freire, C. S. R., Silvestre, A. J. D., & Neto, C. P. (2011). Utilization of residues from agro-forest industries in the production of high value bacterial cellulose. Bioresource Technology, 102(15), 7354–7360.

Tanskul, S., Amornthatree, K., & Jaturonlak, N. (2013). A new cellulose-producing bacterium, Rhodococcus sp. MI 2: screening and optimization of culture conditions. Carbohydrate Polymers, 92(1), 421–428.

Shi, Z., Zhang, Y., Phillips, G. O., & Yang, G. (2014). Utilization of bacterial cellulose in food. Food Hydrocolloids, 35, 539–545.

Lin, S., Calvar, I. L., Catchmark, J. M., Liu, J., Demirci, A., & Cheng, K. (2013). Biosynthesis, production and applications of bacterial cellulose. Cellulose, 20(5), 2191–2219.

Okiyama, A., Motoki, M., & Yamanaka, S. (1993). Bacterial cellulose IV. Application to processed foods. Food Hydrocolloids, 6(6), 503–511.

Phisalaphong, M., & Chiaoprakobkij, N. (2012). Applications and products: nata de coco. In M. Gama, P. Gatenholm, & D. Klemm (Eds.), Bacterial nanocellulose: a sophisticated multifunctional material (pp. 143–156). Boca Raton: CRC Press.

Yanti, N. A., Ahmad, S. W., Ambardini, S., & Muhiddin, N. H. (2017). Screening of acetic acid bacteria from pineapple by-product for bacterial cellulose production using sago liquid by-product. Biosaintifika: Journal of Biology & Biology Education, 9(3), 387–393.

Stepanov, N., & Efremenko, E. (2018). “Deceived” concentrated immobilized cells as biocatalyst for intensive bacterial cellulose production from various sources. Catalysts, 8(1), 33.

Kiziltas, E. E., Kiziltas, A., & Gardner, D. J. (2015). Synthesis of bacterial cellulose using hot water extracted wood sugars. Carbohydrate Polymers, 124, 131–138.

Gomes, F. P., Silva, N. H. C. S., Trovatti, E., Serafim, L. S., Duarte, M. F., Silvestre, A. J. D., Neto, C. P., & Freire, C. S. R. (2013). Production of bacterial cellulose by Gluconacetobacter sacchari using dry olive mill residue. Biomass and Bioenergy, 55, 205–211.

Istalaksana, P., Gandhi, Y., Hadi, P., Rochani, A., Mbaubedari, K., & Bachri, S. (2005). Conversion of natural sago forest into a sustainable sago palm plantation at Masirei District, Waropen, Papua, Indonesia: feasibility study. In Karafir, Y.O., Jong, F.S., & Fere, E. (Eds.), Proceedings of the 8th International Sago Symposium Monokwari (pp. 65–77). Manokwari: Universitas Negeri Papua Press.

Ministry of Plantation Industries and Commodities (MPIC). (2014). Malaysia: basic statistics on sago. Available from: www.kppk.gov.my/mpic/index.php/en/statistic-on-commodity/dataset/826-sago-tembakau. Accessed 16 Dec 2016.

Lai, J. C., Rahman, W. A. W. A., & Toh, W. Y. (2013). Characterisation of sago pith by-product and its composites. Industrial Crops and Products, 45, 319–326.

Kumoro, A. C., Ngoh, G. C., Hasan, M., Ong, C. H., & Teoh, E. C. (2008). Conversion of fibrous sago (Metroxylon sagu) by-product into fermentable sugar via acid and enzymatic hydrolysis. Asian Journal of Scientific Research, 4, 412–420.

Adeni, D. S. A., Bujang, K. B., Hassan, M. A., & Abd-Aziz, S. (2013). Recovery of glucose from residual starch of sago hampas for bioethanol production. Journal of Biomed Research International, 2013, 1-8.

Voon, W. W. Y., Rukayadi, Y., & Meor Hussin, A. S. (2016). Isolation and identification of bio-cellulose-producing bacterial strains from Malaysian acidic fruits. Letters in Applied Microbiology, 62(5), 428–433.

Aydin, Y. A., & Aksoy, N. D. (2009). Isolation of cellulose producing bacteria from wastes of vinegar fermentation. In Proceedings of the World Congress on Engineering and Computer Science 2009 (Vol I). San Francisco: WCECS.

Kurosumi, A., Sasaki, C., Yamashita, Y., & Nakamura, Y. (2009). Utilization of various fruit juices as carbon source for production of bacterial cellulose by Acetobacter xylinum NBRC 13693. Carbohydrate Polymers, 76(2), 333–335.

Zakaria, J., & Nazeri, M. A. (2012). Optimization of bacterial cellulose production from pineapple waste: Effect of temperature, pH and concentration. In 5th Engineering Conference, “Engineering Towards Change – Empowering Green Solutions”, 10-12th July 2012, Kuching Sarawak.

Halib, N., Amin, M. C. I. M., & Ahmad, I. (2012). Physicochemical properties and characterization of Nata de coco from local food industries as a source of cellulose. Sains Malaysiana, 41, 205–211.

Mohammadkazemi, F., Azin, M., & Ashori, A. (2015). Production of bacterial cellulose using different carbon sources and culture media. Carbohydrate Polymers, 117, 518–523.

Sheykhnazari, S., Tabarsa, T., Ashori, A., Shakeri, A., & Golalipour, M. (2011). Bacterial synthesized cellulose nanofibers: effects of growth times and culture mediums on the structural characteristics. Carbohydrate Polymers, 86(3), 1187–1191.

Ved, C. H., More, N. S., Bharate, S. S., & Bharate, S. B. (2010). Cytotoxicity screening of selected Indian medicinal plants using brine-shrimp lethality bioassay. Advances in Natural and Applied Sciences, 4, 389–395.

Funding

The present study was supported by grant (UPM/700 – 1/2/Geran Putra) from the Universiti Putra Malaysia, 43400 UPM Serdang, Selangor Darul Ehsan, Malaysia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Research Highlights

• Sago by-product was used as a carbon source for bio-cellulose (BC) production.

• Beijerinckia fluminensis WAUPM53 was used to produce BC.

• FTIR confirmed the pellicle produced was BC.

• BSLT result showed no toxicity of bio-cellulose produced in sago by-product medium.

Rights and permissions

About this article

Cite this article

Voon, W.W.Y., Muhialdin, B.J., Yusof, N.L. et al. Bio-cellulose Production by Beijerinckia fluminensis WAUPM53 and Gluconacetobacter xylinus 0416 in Sago By-product Medium. Appl Biochem Biotechnol 187, 211–220 (2019). https://doi.org/10.1007/s12010-018-2807-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-018-2807-2