Abstract

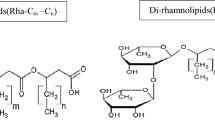

Coconut oil sludge and oil cake was utilized as carbon source for biosurfactant production by Pseudomonas aeruginosa AMB AS7. The results of optimization study revealed that 1.5% (w/v) of coconut oil cake, 2% (w/v) of coconut oil sludge, pH 7.2, 37 °C, and 120 rpm were the optimum conditions for biosurfactant production. The yield coefficient of biosurfactant on biomass (Y P/X ) was 1.29 g/g. Besides, the results indicated that aeration of 0.5 vvm and agitation of 450 rpm in bioreactor resulted in high volumetric productivity of biosurfactant (r p ) and specific product formation rate (q p ) of 0.115 g/(L h) and 0.0131 g/(g h), respectively in medium containing 2% (w/v) coconut oil sludge. The maximum biosurfactant concentration of 5.53 g/L was obtained during 60 h of cultivation. The emulsification index (EI24) against coconut oil was found to be 88.42 ± 0.5%, and cell surface hydrophobicity of P. aeruginosa AMB AS7 was obtained 32.4 ± 0.9%. FTIR and GC-MS analysis revealed that the biosurfactant is rhamnolipid with anionic charge. The critical micelle concentration (CMC) of rhamnolipid was found to be 50 mg/L. It was found that 66.95% of chromium from aqueous solution can be removed using rhamnolipid at its CMC.

Similar content being viewed by others

Reference

Biosurfactants market by product (rhamnolipids, sophorolipids, MES, APG, sorbitan esters, sucrose esters) expected to reach USD 2308.8 Million by 2020 2014. Available from: http://www.grandviewresearch.com/industryanalysis/biosurfactants-industry.

Van Hamme, J. D., Singh, A., & Ward, O. P. (2006). Physiological aspects: part 1 in a series of papers devoted to surfactants in microbiology and biotechnology. Biotechnology Advances, 24, 604–620.

Henkel, M., Müller, M. M., Kügler, J. H., Lovaglio, R. B., Contiero, J., Syldatk, C., & Hausmann, R. (2012). Rhamnolipids as biosurfactants from renewable resources: concepts for next-generation rhamnolipid production. Process Biochemistry, 47, 1207–1219.

Banat, I. M., Satpute, S. K., Cameotra, S. S., Patil, R., & Nyayanit, N. V. (2014). Cost effective technologies and renewable substrates for biosurfactants’ production. Frontiers in Microbiology, 5, 697–715.

Gudiña, E. J., Rodrigues, A. I., Alves, E., Domingues, M. R., Teixeira, J. A., & Rodrigues, L. R. (2015). Bioconversion of agro-industrial by-products in rhamnolipids toward applications in enhanced oil recovery and bioremediation. Bioresource Technology, 177, 87–93.

Chooklin, C. S., Maneerat, S., & Saimmai, A. (2014). Utilization of banana peel as a novel substrate for biosurfactant production by Halobacteriaceae archaeon AS65. Applied Biochemistry and Biotechnology, 173, 624–645.

Patowary, R., Patowary, K., Kalita, M. C., & Deka, S. (2016). Utilization of paneer whey waste for cost-effective production of rhamnolipid biosurfactant. Applied Biochemistry and Biotechnology, 180, 383–399.

Bhardwaj, G., Cameotra, S. S., & Chopra, H. K. (2015). Utilization of oil industry residues for the production of rhamnolipids by Pseudomonas indica. Journal of Surfactants and Detergents, 18, 887–893.

George, S., & Jayachandran, K. (2009). Analysis of rhamnolipid biosurfactants produced through submerged fermentation using orange fruit peelings as sole carbon source. Applied Biochemistry and Biotechnology, 158, 694–705.

Maddipati, P., Atiyeh, H. K., Bellmer, D. D., & Huhnke, R. L. (2011). Ethanol production from syngas by Clostridium strain P11 using corn steep liquor as a nutrient replacement to yeast extract. Bioresource Technology, 102, 6494–6501.

De Sousa, J. R., da Costa Correia, J. A., De Almeida, J. G. L., Rodrigues, S., Pessoa, O. D. L., Melo, V. M. M., & Gonçalves, L. R. B. (2011). Evaluation of a co-product of biodiesel production as carbon source in the production of biosurfactant by P. aeruginosa MSIC02. Process Biochemistry, 46, 1831–1839.

Venkatesh, N. M., & Vedaraman, N. (2012). Remediation of soil contaminated with copper using rhamnolipids produced from Pseudomonas aeruginosa MTCC 2297 using waste frying rice bran oil. Annals of Microbiology, 62, 85–91.

Ramírez, I. M., Tsaousi, K., Rudden, M., Marchant, R., Alameda, E. J., Román, M. G., & Banat, I. M. (2015). Rhamnolipid and surfactin production from olive oil mill waste as sole carbon source. Bioresource Technology, 198, 231–236.

Jayabarath, J., Shyam, S., Arulmurugan, R., & Giridhar, R. (2009). Bioremediation of heavy metals using biosurfactants. Int J Biotechnol Appl, 1, 50–54.

Sarin, V., & Pant, K. K. (2006). Removal of chromium from industrial waste by using eucalyptus bark. Bioresource Technology, 97, 15–20.

Ozturk, S., Aslim, B., & Suludere, Z. (2009). Evaluation of chromium (VI) removal behaviour by two isolates of Synechocystis sp. in terms of exopolysaccharide (EPS) production and monomer composition. Bioresource Technology, 100, 5588–5593.

Dunn Jr., R. O., Scamehorn, J. F., & Christian, S. D. (1985). Use of micellar-enhanced ultrafiltration to remove dissolved organics from aqueous streams. Separation Science and Technology, 20, 257–284.

Landaburu-Aguirre, J., García, V., Pongrácz, E., & Keiski, R. L. (2009). The removal of zinc from synthetic wastewaters by micellar-enhanced ultrafiltration: statistical design of experiments. Desalination, 240, 262–269.

Dubois, M., Gilles, K. A., Hamilton, J. K., Rebers, P., & Smith, F. (1956). Colorimetric method for determination of sugars and related substances. Analytical Chemistry, 28, 350–356.

Nitschke, M., & Pastore, G. M. (2006). Production and properties of a surfactant obtained from Bacillus subtilis grown on cassava wastewater. Bioresource Technology, 97, 336–341.

Cooper, D. G., & Goldenberg, B. G. (1987). Surface-active agents from two Bacillus species. Applied and Environmental Microbiology, 53, 224–229.

Mishra, S., & Singh, S. (2012). Microbial degradation of n-hexadecane in mineral salt medium as mediated by degradative enzymes. Bioresource Technology, 111, 148–154.

Rosenberg, M., Gutnick, D., & Rosenberg, E. (1980). Adherence of bacteria to hydrocarbons: a simple method for measuring cell-surface hydrophobicity. FEMS Microbiology Letters, 9, 29–33.

Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72, 248–254.

Aparna, A., Srinikethan, G., & Smitha, H. (2012). Production and characterization of biosurfactant produced by a novel Pseudomonas sp. 2B. Colloids and Surfaces B: Biointerfaces, 95, 23–29.

Abalos, A., Pinazo, A., Infante, M., Casals, M., Garcia, F., & Manresa, A. (2001). Physicochemical and antimicrobial properties of new rhamnolipids produced by Pseudomonas aeruginosa AT10 from soybean oil refinery wastes. Langmuir, 17, 1367–1371.

Meylheuc, T., Van Oss, C., & Bellon-Fontaine, M. N. (2001). Adsorption of biosurfactant on solid surfaces and consequences regarding the bioadhesion of Listeria monocytogenes LO28. Journal of Applied Microbiology, 91, 822–832.

Eaton, A. D., Clesceri, L. S., Association, A. P. H., Greenberg, A. E., Federation, W. P. C., Association, A. W. W., Franson, A. H., & Federation, W. E. (1995). Standard methods for the examination of water and wastewater. ed. American Public Health Association.

Liu, B., Liu, J., Ju, M., Li, X., & Yu, Q. (2016). Purification and characterization of biosurfactant produced by Bacillus licheniformis Y-1 and its application in remediation of petroleum contaminated soil. Marine Pollution Bulletin, 107, 46–51.

San Keskin, N. O., Han, D., Ozkan, A. D., Angun, P., Umu, O. C. O., & Tekinay, T. (2015). Production and structural characterization of biosurfactant produced by newly isolated Staphylococcus xylosus STF1 from petroleum contaminated soil. Journal of Petroleum Science and Engineering, 133, 689–694.

George, S., & Jayachandran, K. (2013). Production and characterization of rhamnolipid biosurfactant from waste frying coconut oil using a novel Pseudomonas aeruginosa D. Journal of Applied Microbiology, 114, 373–383.

Abdel-Mawgoud, A. M., Aboulwafa, M. M., & Hassouna, N. A.-H. (2009). Characterization of rhamnolipid produced by Pseudomonas aeruginosa isolate Bs20. Applied Biochemistry and Biotechnology, 157, 329–345.

Neu, T. R. (1996). Significance of bacterial surface-active compounds in interaction of bacteria with interfaces. Microbiological Reviews, 60, 151.

Al-Tahhan, R. A., Sandrin, T. R., Bodour, A. A., & Maier, R. M. (2000). Rhamnolipid-induced removal of lipopolysaccharide from Pseudomonas aeruginosa: effect on cell surface properties and interaction with hydrophobic substrates. Applied and Environmental Microbiology, 66, 3262–3268.

Mariaamalraj, S. K., Pasumarthi, R., Achary, A., & Mutnuri, S. (2016). Effect of rhamnolipid on biodegradation of hydrocarbons in non-aqueous-phase liquid (NAPL). Bioremediation Journal, 20, 183–193.

Das, K., & Mukherjee, A. (2007). Differential utilization of pyrene as the sole source of carbon by Bacillus subtilis and Pseudomonas aeruginosa strains: role of biosurfactants in enhancing bioavailability. Journal of Applied Microbiology, 102, 195–203.

Zhao, Z., Selvam, A., & Wong, J. W.-C. (2011). Effects of rhamnolipids on cell surface hydrophobicity of PAH degrading bacteria and the biodegradation of phenanthrene. Bioresource Technology, 102, 3999–4007.

Thavasi, R., Jayalakshmi, S., & Banat, I. M. (2011). Application of biosurfactant produced from peanut oil cake by Lactobacillus delbrueckii in biodegradation of crude oil. Bioresource Technology, 102, 3366–3372.

Lotfabad, T. B., Shourian, M., Roostaazad, R., Najafabadi, A. R., Adelzadeh, M. R., & Noghabi, K. A. (2009). An efficient biosurfactant-producing bacterium Pseudomonas aeruginosa MR01, isolated from oil excavation areas in south of Iran. Colloids and Surfaces B: Biointerfaces, 69, 183–193.

Dusane, D. H., Zinjarde, S. S., Venugopalan, V. P., Mclean, R. J., Weber, M. M., & Rahman, P. K. (2010). Quorum sensing: implications on rhamnolipid biosurfactant production. Biotechnology and Genetic Engineering Reviews, 27, 159–184.

Rodrigues, L., Moldes, A., Teixeira, J., & Oliveira, R. (2006). Kinetic study of fermentative biosurfactant production by Lactobacillus strains. Biochemical Engineering Journal, 28, 109–116.

de Oliveira, D. W. F., França, Í. W. L., Félix, A. K. N., Martins, J. J. L., Giro, M. E. A., Melo, V. M. M., & Gonçalves, L. R. B. (2013). Kinetic study of biosurfactant production by Bacillus subtilis LAMI005 grown in clarified cashew apple juice. Colloids and Surfaces B: Biointerfaces, 101, 34–43.

Das Neves, L. C. M., De Oliveira, K. S., Kobayashi, M. J., Penna, T. C. V. & Converti, A. (2007). Biosurfactant production by cultivation of Bacillus atrophaeus ATCC 9372 in semidefined glucose/casein-based media. In Applied Biochemistry and Biotecnology (pp. 539–554). Berlin Heidelberg New York: Springer.

Mercade, M., Manresa, M., Robert, M., Espuny, M., De Andres, C., & Guinea, J. (1993). Olive oil mill effluent (OOME). New substrate for biosurfactant production. Bioresource Technology, 43, 1–6.

Benincasa, M., & Accorsini, F. R. (2008). Pseudomonas aeruginosa LBI production as an integrated process using the wastes from sunflower-oil refining as a substrate. Bioresource Technology, 99, 3843–3849.

Silva, S. N. R. L., Farias, C. B. B., Rufino, R. D., Luna, J. M., & Sarubbo, L. A. (2010). Glycerol as substrate for the production of biosurfactant by Pseudomonas aeruginosa UCP0992. Colloids and Surfaces B: Biointerfaces, 79, 174–183.

Luna, J. M., Rufino, R. D., Sarubbo, L. A., & Campos-Takaki, G. M. (2013). Characterisation, surface properties and biological activity of a biosurfactant produced from industrial waste by Candida sphaerica UCP0995 for application in the petroleum industry. Colloids and Surfaces B: Biointerfaces, 102, 202–209.

Abbasi, H., Hamedi, M. M., Lotfabad, T. B., Zahiri, H. S., Sharafi, H., Masoomi, F., Moosavi-Movahedi, A. A., Ortiz, A., Amanlou, M., & Noghabi, K. A. (2012). Biosurfactant-producing bacterium, Pseudomonas aeruginosa MA01 isolated from spoiled apples: physicochemical and structural characteristics of isolated biosurfactant. Journal of Bioscience and Bioengineering, 113, 211–219.

Nalini, S., & Parthasarathi, R. (2013). Biosurfactant production by Serratia rubidaea SNAU02 isolated from hydrocarbon contaminated soil and its physico-chemical characterization. Bioresource Technology, 147, 619–622.

Thavasi, R., Jayalakshmi, S., Balasubramanian, T., & Banat, I. M. (2008). Production and characterization of a glycolipid biosurfactant from Bacillus megaterium using economically cheaper sources. World Journal of Microbiology and Biotechnology, 24, 917–925.

Haba, E., Pinazo, A., Jauregui, O., Espuny, M., Infante, M. R., & Manresa, A. (2003). Physicochemical characterization and antimicrobial properties of rhamnolipids produced by Pseudomonas aeruginosa 47T2 NCBIM 40044. Biotechnology and Bioengineering, 81, 316–322.

Pornsunthorntawee, O., Wongpanit, P., Chavadej, S., Abe, M., & Rujiravanit, R. (2008). Structural and physicochemical characterization of crude biosurfactant produced by Pseudomonas aeruginosa SP4 isolated from petroleum-contaminated soil. Bioresource Technology, 99, 1589–1595.

Mulligan, C. N., Yong, R. N., & Gibbs, B. F. (2001). Heavy metal removal from sediments by biosurfactants. Journal of Hazardous Materials, 85, 111–125.

Sang, Y., Gu, Q., Sun, T., Li, F., & Liang, C. (2008). Filtration by a novel nanofiber membrane and alumina adsorption to remove copper (II) from groundwater. Journal of Hazardous Materials, 153, 860–866.

Wang, S., & Mulligan, C. N. (2004). Rhamnolipid foam enhanced remediation of cadmium and nickel contaminated soil. Water, Air, and Soil Pollution, 157, 315–330.

Mulligan, C. N., Yong, R. N., & Gibbs, B. F. (1999). Removal of heavy metals from contaminated soil and sediments using the biosurfactant surfactin. Journal of Soil Contamination, 8, 231–254.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

ESM 1

(PDF 10014 kb)

Rights and permissions

About this article

Cite this article

Samykannu, M., Achary, A. Utilization of Agro-Industry Residue for Rhamnolipid Production by P. aeruginosa AMB AS7 and Its Application in Chromium Removal. Appl Biochem Biotechnol 183, 70–90 (2017). https://doi.org/10.1007/s12010-017-2431-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2431-6