Abstract

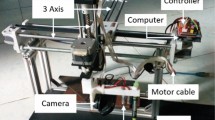

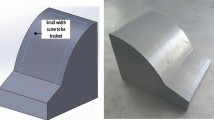

Welding automation is one of the highly applied research that receives a lot of interest from scientists as well as application engineers in the industry. The welding task can be tedious for the workers; health affected by chemical smoke; or activity performed in a human restricted area. However, at present, manual teaching using Tech-pendant and off-line programming are still used in most industrial applications especially 3D complex curve welding. In order to improve the quality and quantity of the welding task, this research presents an effective automated method for extracting 3D curve seam welding using industrial robot. Firstly, by using a low cost 3D Camera and laser system which are attached at the end-effector of 6-DOF manipulator and combining with laser triangular image processing algorithm the position of path from start, mid, auxiliary, and end points coordinated of the welding line are recorded. Then by using interpolation algorithm the trajectory is calculated and transmitted to the 6DOF manipulator. As known that the angle of the weld head is also very important to the quality of the weld, so this research also proposes the method to adjust this angle during welding. Through implement experiments, the system proved that it is stable and have good precision. Installation time and maintaining are fast, not complicated and meet the automation demand.

Similar content being viewed by others

Availability of data and materials

Not applicable.

References

Ma, H., Wei, S., Sheng, Z., Lin, T., Chen, S.: Robot welding seam tracking method based on passive vision for thin plate closed-gap butt welding. Int. J. Adv. Manuf. Technol. 48, 945–953 (2010). https://doi.org/10.1007/s00170-009-2349-4

Automation world, Yaskawa Motoman: Teaching Technology for Welding Robots, https://www.automationworld.com/factory/robotics/product/13310598/yaskawa-motoman-teaching-technology-for-welding-robots

Rout, A., Deepak, B.B.V.L., Biswal, B.B.: Advances in weld seam tracking techniques for robotic welding: a review. Robot. Computer-Integrated Manuf 56, 12–37 (2019)

Liu, Y., Tang, Q., Tian, X.: A discrete method of sphere-pipe intersecting curve for robot welding by offline programming. Robot. Computer-Integrated Manuf. 57, 404–411 (2019)

ABB, Weldguide IV, The most powerful robotic Thru-the-Arc joint tracking on the market, https://new.abb.com/products/robotics/application-equipment-and-accessories/arc-welding-equipment/process-support-tools/weldguide

Cook, G. E., Andersen, K., Fernandez, K. R., Shepard, M. E., Wells, A. M. Jr.: “Electric arc sensing for robot positioning control”, IFS(Publications) Ltd., Robotic Welding, 181–216 (2010)

Fridenfalk, M., Bolmsjo, G.: Design and validation of a universal 6D seam-tracking system in robotic welding using arc sensing. Adv Robot 18, 1–21 (2004)

Arc Sensor by Daihen, USA, (https://www.daihen-usa.com/product/fd-tr-tig-arcsensor/). Accessed: 2018–06–26.

Suwanratchatamanee, K., Matsumoto, M., Hashimoto, S.: Robotic tactile sensor system and applications. IEEE Trans. Industr. Electron. 57(3), 1074–1087 (2010)

Xu, Y., Lv, N., Zhong, J., Chen, H., Chen, S.: Research on the real-time tracking information of three-dimension welding seam in robotic GTAW process based on composite sensor technology. J. Intell. Rob. Syst. 68(2), 89–103 (2012)

Silvers, G.A., Fang, G.: Human machine interface in weld seam detection using an RGB-D camera. Adv. Mater. Res. 875–877, 1967–1971 (2014)

Wang, Q., Jiao, W., Yu, R., Johnson, M.T., Zhang, Y.M.: Virtual reality robot-assisted welding based on human intention recognition. IEEE Trans. Autom. Sci. Eng. 17(2), 799–808 (2020). https://doi.org/10.1109/TASE.2019.2945607

Pablo, R.G., Manuel, R.M.: Weld bead detection based on 3D geometric featuresand machine learning approaches. IEEE Access 7, 14714–14727 (2019). https://doi.org/10.1109/ACCESS.2019.2891367

Panasonic Industry, VRPS (Virtual Robot Programming System), https://industrial.panasonic.com/ww/products-fa/welding/industrial-robots/arc-welding-robot/vrps

Kiddee, P., Fang, Z., Tan, M.: An automated weld seam tracking system for thick plate using cross mark structured light. Int. J. Adv. Manuf. Technol. 87, 3589–3603 (2016). https://doi.org/10.1007/s00170-016-8729-7

Huang, Y., Li, G., Shao, W., Gong, S., Zhang, X.: A novel dual-channel weld seam tracking system for aircraft T-joint welds. Int. J. Adv. Manuf. Technol. 91, 751–761 (2017)

Zou, Y., Li, Y., Jiang, L., Xue, L.: Weld pool image processing algorithm for seam tracking of welding robot. In: 6th IEEE Conference on Industrial Electronics and Applications, Beijing, China, Jun. 2011, pp. 161–165

Xu, Y., Fang, G., Lv, N., Chen, S., Zou, J.J.: Computer vision technology for seam tracking in robotic GTAW and GMAW. Robot. Computer-Integrated Manuf. 32, 25–36 (2015)

Dinham, M., Fang, G.: Autonomous weld seam identification and localisation using eye-in-hand stereo vision for robotic arc welding. Robot. Computer-Integrated Manuf. 29(5), 288–301 (2013)

Zhou, L., Lin, T., Chen, S.-B.: Autonomous acquisition of seam coordinates for arc welding robot based on visual servoing. J. Intell. Rob. Syst. 47(3), 239–255 (2006)

Shen, H., Lin, T., Chen, S., Li, L.: Real-time seam tracking technology of welding robot with visual sensing. J. Intell. Rob. Syst. 59(3–4), 283–298 (2010)

Shen, H.Y., Wu, J., Lin, T., Chen, S.B.: Arc welding robot with seam tracking and weld pool control based on passive vision. J. Adv. Manuf. Technol. 39(7–8), 669–678 (2008)

Xiao, R., Xu, Y., Hou, Z., Chen, C., Chen, S.: An adaptive feature extraction algo-rithm for multiple typical seam tracking based on vision sensor in robotic arcwelding. Sens. Actuators, A 297, 111533 (2019). https://doi.org/10.1016/j.sna.2019.111533

Liu, J., Fan, Z., Olsen, S.I., Christensen, K.H., Kristensen, J.K.: Boosting active contours for weld pool visual tracking in automatic arc welding. IEEE Trans. Autom. Sci. Eng. 14(2), 1096–1108 (2017)

Xu, Y., Yu, H., Zhong, J., Lin, T., Chen, S.: Real-time seam tracking control technology during welding robot GTAW process based on passive vision sensor. J. Mater. Process. Technol. 212(8), 1654–1662 (2012)

Xiong, J., Pi, Y., Chen, H.: Deposition height detection and feature point extrac-tion in robotic GTA-based additive manufacturing using passive vision sensing. Robot. Computer-Integrated Manuf. 59, 326–334 (2019). https://doi.org/10.1016/j.rcim.2019.05.006

Li, J., Yang, P., Huang, L., Xiao, M.: Recognition of initial welding position forlarge diameter pipeline based on pulse coupled neural network. Ind. Robot. 42, 339–346 (2015). https://doi.org/10.1108/IR-01-2015-0011

Jin, Z., Li, H., Zhang, C., Wang, Q., Gao, H.: Online welding path detection in auto-matic tube-to-tubesheet welding using passive vision. Int. J. Adv. Manuf. Technol. 90, 3075–3084 (2017). https://doi.org/10.1007/s00170-016-9649-2

Yang, L., Li, E., Long, T., Fan, J., Liang, Z.: A high-speed seam extraction method based on the novel structured-light sensor for arc welding robot: a review. IEEE Sens. J. 18(21), 8631–8641 (2018)

Du, J., Yong, L.Y., Sun, M., Ge, J.S.: Study on stereo vision for 3D reconstruction of welding seam. Adv. Mater. Res. 850–851, 212–216 (2013)

Muhammad, J., Altun, H., Abo-Serie, E.: A robust butt welding seam findingtechnique for intelligent robotic welding system using active laser vision. Int. J. Adv. Manuf. Technol. 94, 13–29 (2018). https://doi.org/10.1007/s00170-016-9481-8

Fan, J., Jing, F., Yang, L., Teng, L., Tan, M.: A precise initial weld point guidingmethod of micro-gap weld based on structured light vision sensor. IEEE Sens. J. 19, 322–331 (2019). https://doi.org/10.1109/JSEN.2018.2876144

Du, R.Q., Xu, Y., Hou, Z., Shu, J., Chen, S.: Strong noise image processing for vision-based seam tracking in robotic gas metal arc welding. Int. J. Adv. Manuf. Technol. 101, 2135–2149 (2019)

Li, Y., Hu, M., Taiyong, W.: Weld image recognition algorithm based on deep learning. Int. J. Pattern Recognit. Artif. Intell. 34(08), 2052004 (2020)

Rodríguez-Gonzálvez, P., Rodríguez-Martín, M.: Weld bead detection based on 3D geometric features and machine learning approaches. IEEE Access 7, 14714–14727 (2019). https://doi.org/10.1109/ACCESS.2019.2891367

Yang, L., Liu, Y., Peng, J.: An automatic detection and identification method of welded joints based on deep neural network. IEEE Access 7, 164952–164961 (2019). https://doi.org/10.1109/ACCESS.2019.2953313

Hanh, L.D., Tu, H.B.: Computer vision for industrial robot in planar bin picking application. Adv. Sci., Technol. Eng. Syst. J. 5(6), 1244–1249 (2020)

Zmarzły, P.: Technological heredity of the turning process. Tehnički Vjesnik. 27, 11–25 (2020). https://doi.org/10.17559/TV-20190425150325

Acknowledgements

We acknowledgment the support of time and facilities from Ho Chi Minh City University of Technology (HCMUT), VNU-HCM for this study

Author information

Authors and Affiliations

Contributions

LDH: Testing, Writing and review. HTP: Coding and testing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval and consent to participate

The authors consent to participate in this work.

Consent for publication

The authors consent for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hanh, L.D., Phuc, H.T. Simultaneously extract 3D seam curve and weld head angle for robot arm using passive vision. Int J Interact Des Manuf 16, 1125–1134 (2022). https://doi.org/10.1007/s12008-021-00801-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-021-00801-0