Abstract

Failure mode and effect analysis (FMEA) technique has been widely used for evaluating potential failures in different kinds of industries. In FMEA, failure modes are evaluated and ordered through the risk priority number (RPN), which is obtained by production of three risk factors including severity (S), occurrence (O), and detection (D) of potential failure modes. However, conventional FMEA has considerable shortages due to various reasons which uncertainty and ambiguity is the significant one. This paper proposes an interactive approach using fuzzy set theory to deal with possible uncertainties during evaluation. Analytical hierarchy process and entropy technique utilized in order to handle the subjective and objective uncertainty weight, respectively. To demonstrate the application of proposed approach, a practical example in construction period of a refinery is surveyed and potential failure modes are prioritized. Finally, a sensitivity analysis is carried out to verify the validity of risk ranking and the proposed approach. Subsequently, a comparison is conducted to illustrate the superiority of the proposed FMEA with conventional ones.

Similar content being viewed by others

References

Stamatis, D.H.: Failure mode and effect analysis: FMEA from theory to execution. Technometrics (2003). https://doi.org/10.2307/1268911

Chen, J.K.: Utility priority number evaluation for FMEA. J. Fail. Anal. Prev. 7, 321–328 (2007). https://doi.org/10.1007/s11668-007-9060-2

Sankar, N.R., Prabhu, B.S.: Modified approach for prioritization of failures in a system failure mode and effects analysis. Int. J. Qual. Reliab. Manag. 18, 324–335 (2013). https://doi.org/10.1108/MRR-09-2015-0216

Markowski, A.S., Mannan, M.S.: Fuzzy risk matrix. J. Hazard. Mater. 159, 152–157 (2008). https://doi.org/10.1016/j.jhazmat.2008.03.055

Liu, H.-C., Liu, L., Liu, N.: Risk evaluation approaches in failure mode and effects analysis: a literature review. Expert Syst. Appl. 40, 828–838 (2013). https://doi.org/10.1016/j.eswa.2012.08.010

Korayem, M.H., Iravani, A.: Improvement of 3P and 6R mechanical robots reliability and quality applying FMEA and QFD approaches. Robot. Comput. Integr. Manuf. 24, 472–487 (2008). https://doi.org/10.1016/j.rcim.2007.05.003

Garrick, B.J.: The approach to risk analysis in three industries: nuclear power, space systems, and chemical process. Reliab. Eng. Syst. Saf. 23, 195–205 (1988). https://doi.org/10.1016/0951-8320(88)90109-3

McNally, K.M., Page, M.A., Sunderland, V.B.: Failure-mode and effects analysis in improving a drug distribution system. Am. J. Health Syst. Pharm. 54, 171–177 (1997)

Zhang, Y., Andrews, J., Reed, S., Karlberg, M.: Maintenance processes modelling and optimisation. Reliab. Eng. Syst. Saf. (2017). https://doi.org/10.1016/j.ress.2017.02.011

Institute of Electrical and Electronics Engineers, M. IEEE Aerospace Conference 2014.03.01-08 Big Sky, IEEE Aerospace Conference, 2014 1–8 March 2014, Yellowstone Conference Center, Big Sky, Montana, IEEE (2014)

International Society for Pharmacoepidemiology: International Society of Pharmacovigilance. Pharmacoepidemiology and Drug Safety. Wiley, Hoboken (2011)

Su, C.-T., Lin, H.-C., Teng, P.-W., Yang, T.: Improving the reliability of electronic paper display using FMEA and Taguchi methods: a case study. Microelectron. Reliab. 54, 1369–1377 (2014). https://doi.org/10.1016/j.microrel.2014.02.015

ICRSE 1. 2015 Peking, Wang, Z., Zhang, S.: Reliability Society, International Conference on Reliability Systems Engineering 1 2015.10.21-23 Beijing, ICRSE 1 2015.10.21-23 Beijing, 2015 ICRSE 21–23 October 2015, Vision Hotel, Beijing, China: Proceedings of the 2015 First International Conference on Reliability Systems Engineering, IEEE (2015)

American Society of Mechanical Engineers. Nuclear Engineering Division, Nihon Kikai Gakkai, Zhongguo he xue hui, Proceedings of the 21st International Conference on Nuclear Engineering–2013: Presented at 2013 21st International Conference on Nuclear Engineering, July 29–August 2, 2013, Chengdu, China (2014)

Wu, Z., Ming, X.G., Song, W., Zhu, B., Xu, Z.: Nuclear product design knowledge system based on FMEA method in new product development. Arab. J. Sci. Eng. 39, 2191–2203 (2014). https://doi.org/10.1007/s13369-013-0726-7

Joo, B., Kim, S., Kim, S., Moon, Y.H.: FMEA for the reliability of hydroformed flanged part for automotive application. J. Mech. Sci. Technol. 27, 63–67 (2013). https://doi.org/10.1007/s12206-012-1226-5

de Aguiar, D.C., Salomon, V.A.P., Mello, C.H.P.: An ISO 9001 based approach for the implementation of process FMEA in the Brazilian automotive industry. Int. J. Qual. Reliab. Manag. 32, 589–602 (2015). https://doi.org/10.1108/EL-01-2014-0022

Jong, C.H., Tay, K.M., Lim, C.P.: Application of the fuzzy failure mode and effect analysis methodology to edible bird nest processing. Comput. Electron. Agric. 96, 90–108 (2013). https://doi.org/10.1016/j.compag.2013.04.015

Dargahi, M.D., Naderi, S., Hashemi, S.A., Aghaiepour, M., Nouri, Z., Sahneh, S.K.: Use FMEA method for environmental risk assessment in ore complex on wildlife habitats. Hum. Ecol. Risk Assess. 22, 1123–1132 (2016). https://doi.org/10.1080/10807039.2015.1106912

Amirul Bin Yusof, M., Hanie, N., Abdullah, B.: Failure mode and effect analysis (FMEA) of butterfly valve in oil and gas industry. J. Eng. Sci. Technol. Spec. Issue ICE ICIE 11, 9–19 (2015)

Modarres, M., Kaminskly, M., Krivtsov, V.: Reliability Engineering and Risk Analysis. Marcel Dekker, New York (1999)

Signor, M.C.: The failure-analysis matrix: a kinder, gentler alternative to FMEA for information systems. In: Annual Reliability and Maintainability Symposium, 2002. Proceedings, pp. 173–177 (2002). https://doi.org/10.1109/rams.2002.981637

McDermott, R.E., Mikulak, R.J., Beauregard, M.R.: The Basics of FMEA. CRC Press, Boca Raton (2009)

Liu, H.: FMEA Using Uncertainty Theories and MCDM Methods. Springer, Singapore (2016). https://doi.org/10.1007/978-981-10-1466-6

Yazdi, M., Daneshvar, S., Setareh, H.: An extension to fuzzy developed failure mode and effects analysis (FDFMEA) application for aircraft landing system. Saf. Sci. 98, 113–123 (2017). https://doi.org/10.1016/j.ssci.2017.06.009

Helvacioglu, S., Ozen, E.: Fuzzy based failure modes and effect analysis for yacht system design. Ocean Eng. 79, 131–141 (2014). https://doi.org/10.1016/j.oceaneng.2013.12.015

Lin, Q.-L., Wang, D.-J., Lin, W.-G., Liu, H.-C.: Human reliability assessment for medical devices based on failure mode and effects analysis and fuzzy linguistic theory. Saf. Sci. 62, 248–256 (2014). https://doi.org/10.1016/j.ssci.2013.08.022

Hadi-Vencheh, A., Aghajani, M.: Failure mode and effects analysis: a fuzzy group MCDM approach. J. Soft Comput. Appl. 2013, 1–14 (2013). https://doi.org/10.5899/2013/jsca-00016

Sayyadi Tooranloo, H., sadat Ayatollah, A.: A model for failure mode and effects analysis based on intuitionistic fuzzy approach. Appl. Soft Comput. 49, 238–247 (2016). https://doi.org/10.1016/j.asoc.2016.07.047

Liu, H.-C., You, J.-X., Li, P., Su, Q.: Failure mode and effect analysis under uncertainty: an integrated multiple criteria decision making approach. IEEE Trans. Reliab. 65, 1380–1392 (2016). https://doi.org/10.1109/TR.2016.2570567

Chang, W.L., Pang, L.M., Tay, K.M.: Application of self-organizing map to failure modes and effects analysis methodology. Neurocomputing 249, 314–320 (2017). https://doi.org/10.1016/j.neucom.2016.04.073

Zhou, Q., Thai, V.V.: Fuzzy and grey theories in failure mode and effect analysis for tanker equipment failure prediction. Saf. Sci. 83, 74–79 (2016). https://doi.org/10.1016/j.ssci.2015.11.013

Liu, H., Liu, L., Li, P.: Failure mode and effects analysis using intuitionistic fuzzy hybrid weighted Euclidean distance operator. Int. J. Syst. Sci. (2016). https://doi.org/10.1080/00207721.2012.760669

Liu, H., Liu, L., Li, P.: Failure mode and effects analysis using intuitionistic fuzzy hybrid weighted Euclidean distance operator. Int. J. Syst. Sci. 45, 2012–2030 (2014). https://doi.org/10.1080/00207721.2012.760669

Panchal, D., Kumar, D.: Integrated framework for behaviour analysis in a process plant. J. Loss Prev. Process Ind. 40, 147–161 (2016). https://doi.org/10.1016/j.jlp.2015.12.021

Liu, H.-C., You, J.-X., Fan, X.-J., Lin, Q.-L.: Failure mode and effects analysis using D numbers and grey relational projection method. Expert Syst. Appl. 41, 4670–4679 (2014). https://doi.org/10.1016/j.eswa.2014.01.031

Chang, K.H.: Generalized multi-attribute failure mode analysis. Neurocomputing 175, 90–100 (2015). https://doi.org/10.1016/j.neucom.2015.10.039

Chang, K.H.: A more general risk assessment methodology using a soft set-based ranking technique. Soft. Comput. 18, 169–183 (2014). https://doi.org/10.1007/s00500-013-1045-3

Ekmekçioğlu, M., CanKutlu, A.: A fuzzy hybrid approach for fuzzy process FMEA: an application to a spindle manufacturing process. Int. J. Comput. Intell. Syst. 5, 611–626 (2012). https://doi.org/10.1080/18756891.2012.718104

Song, W., Ming, X., Wu, Z., Zhu, B.: Failure modes and effects analysis using integrated weight-based fuzzy TOPSIS. Int. J. Comput. Integr. Manuf. 26, 1172–1186 (2013). https://doi.org/10.1080/0951192X.2013.785027

Chang, K.-H., Chang, Y.-C., Lee, Y.-T.: Integrating TOPSIS and DEMATEL methods to rank the risk of failure of FMEA. Int. J. Inf. Technol. Decis. Mak. 13, 1229–1257 (2014). https://doi.org/10.1142/S0219622014500758

Montgomery, T.A., Pugh, D.R., Leedham, S.T., Twitchett, S.R.: FMEA automation for the complete design process. In: 1996 Proceedings of Annual Reliability and Maintainability Symposium, pp. 30–36 (1996). https://doi.org/10.1109/rams.1996.500638

Legg, J.M.: Computerized approach for matrix-form FMEA. IEEE Trans. Reliab. 27, 254–257 (1978). https://doi.org/10.1109/tr.1978.5220355

OHSAS 18001: Occupational health and safety management systems—requirements. Occupational Health (Auckland) (2007)

Antunes, R., Gonzalez, V.: A production model for construction: a theoretical framework. Buildings 5, 209–228 (2015). https://doi.org/10.3390/buildings5010209

Keynes, J.M.: The General Theory of Employment, Interest, and Money. John Maynard Keynes, New York (1936)

Yazdi, M.: Hybrid probabilistic risk assessment using fuzzy FTA and fuzzy AHP in a process industry. J. Fail. Anal. Prev. 17, 756–764 (2017). https://doi.org/10.1007/s11668-017-0305-4

Yazdi, M., Nikfar, F., Nasrabadi, M.: Failure probability analysis by employing fuzzy fault tree analysis. Int. J. Syst. Assur. Eng. Manag. 8, 1177–1193 (2017). https://doi.org/10.1007/s13198-017-0583-y

Markowski, A.S., Mannan, M.S., Bigoszewska, A.: Fuzzy logic for process safety analysis. J. Loss Prev. Process Ind. 22, 695–702 (2009). https://doi.org/10.1016/j.jlp.2008.11.011

Yazdi, M.: The application of bow-tie method in hydrogen sulfide risk management using layer of protection analysis (LOPA). J. Fail. Anal. Prev. 17, 291–303 (2017). https://doi.org/10.1007/s11668-017-0247-x

Pars Oil and Gas Company (POGC): Learning from Accident (Welding Inside the GRE Pipe). POGC, Kangan (2016). (in persian)

US Nuclear Regulatory Commission, PRA Procedures Guide: A Guide to the Performance of Probabilistic Risk Assessments for Nuclear Power Plants (NUREG/CR-2300). US Nuclear Regulatory Commission, Washington (1983)

Mannan, S., Lees, F.P.: Lees’ Loss Prevention in the Process Industries: Hazard Identification, Assessment, and Control. Elsevier Butterworth-Heinemann, Oxford (2005)

Siler, W., Buckley, J.J.: Fuzzy Expert Systems and Fuzzy Reasoning. Wiley, Hoboken (2004). https://doi.org/10.1002/0471698504

Zadeh, L.: Fuzzy sets. Inf. Control 8, 338–353 (1965). https://doi.org/10.1109/2.53

Gentile, M., Rogers, W.J., Mannan, M.S.: Development of a fuzzy logic-based inherent safety index. Process Saf. Environ. Prot. 81, 444–456 (2003). https://doi.org/10.1205/095758203770866610

Saaty, T.L.: Creative Thinking, Problem Solving and Decision Making. RWS Publications, Pittsburgh (2010)

Guneri, A.F., Gul, M., Ozgurler, S.: A fuzzy AHP methodology for selection of risk assessment methods in occupational safety. Int. J. Risk Assess. Manag. 18, 319 (2015). https://doi.org/10.1504/IJRAM.2015.071222

Yazdi, M., Kabir, S.: A fuzzy Bayesian network approach for risk analysis in process industries. Process Saf. Environ. Prot. 111, 507–519 (2017). https://doi.org/10.1016/j.psep.2017.08.015

Buckley, J.J.: Fuzzy hierarchical analysis. Fuzzy Sets Syst. 17, 233–247 (1985). https://doi.org/10.1016/0165-0114(85)90090-9

Chang, D.-Y.: Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 95, 649–655 (1996). https://doi.org/10.1016/0377-2217(95)00300-2

Yazdi, M., Korhan, O., Daneshvar, S.: Application of fuzzy fault tree analysis based on modified fuzzy AHP and fuzzy TOPSIS for fire and explosion in process industry. Int. J. Occup. Saf. Ergon. (2018). https://doi.org/10.1080/10803548.2018.1454636

Kabir, S., Yazdi, M., Aizpurua, J.I., Papadopoulos, Y.: Uncertainty-aware dynamic reliability analysis framework for complex systems. IEEE Access (2018). https://doi.org/10.1109/access.2018.2843166

Yazdi, M.: An extension of fuzzy improved risk graph and fuzzy analytical hierarchy process for determination of chemical complex safety integrity levels. Int. J. Occup. Saf. Ergon. (2017). https://doi.org/10.1080/10803548.2017.1419654

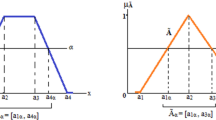

Pedrycz, W.: Why triangular membership functions? Fuzzy Sets Syst. 64, 21–30 (1994). https://doi.org/10.1016/0165-0114(94)90003-5

Aqlan, F., Mustafa Ali, E.: Integrating lean principles and fuzzy bow-tie analysis for risk assessment in chemical industry. J. Loss Prev. Process Ind. 29, 39–48 (2014). https://doi.org/10.1016/j.jlp.2014.01.006

Ross, T.J.: Fuzzy Logic with Engineering Applications. Wiley, Chichester (2009). https://doi.org/10.1002/9781119994374

Ishikawa, A., Amagasa, M., Shiga, T., Tomizawa, G., Tatsuta, R., Mieno, H.: The max–min Delphi method and fuzzy Delphi method via fuzzy integration. Fuzzy Sets Syst. 55, 241–253 (1993). https://doi.org/10.1016/0165-0114(93)90251-C

Yazdi, M., Zarei, E.: Uncertainty handling in the safety risk analysis: an integrated approach based on fuzzy fault tree analysis. J. Fail. Anal. Prev. 18, 392–404 (2018). https://doi.org/10.1007/s11668-018-0421-9

Shannon, C.E.: A mathematical theory of communication. Bell Syst. Tech. J. 27, 379–423 (1948). https://doi.org/10.1002/j.1538-7305.1948.tb01338.x

Chen, S., Leng, Y., Mao, B., Liu, S.: Integrated weight-based multi-criteria evaluation on transfer in large transport terminals: a case study of the Beijing South Railway Station. Transp. Res. Part A Policy Pract. 66, 13–26 (2014). https://doi.org/10.1016/j.tra.2014.04.015

Aghajani Bazzazi, A., Osanloo, M., Karimi, B.: Deriving preference order of open pit mines equipment through MADM methods: application of modified VIKOR method. Expert Syst. Appl. 38, 2550–2556 (2011). https://doi.org/10.1016/j.eswa.2010.08.043

Jing, Y.Y., Bai, H., Wang, J.J.: A fuzzy multi-criteria decision-making model for CCHP systems driven by different energy sources. Energy Policy 42, 286–296 (2012). https://doi.org/10.1016/j.enpol.2011.11.085

Liu, H., You, J., You, X., Shan, M.: A novel approach for failure mode and effects analysis using combination weighting and fuzzy VIKOR method. Appl. Soft Comput. J. 28, 579–588 (2015). https://doi.org/10.1016/j.asoc.2014.11.036

Yazdi, M.: Risk assessment based on novel intuitionistic fuzzy-hybrid-modified TOPSIS approach. Saf. Sci. (2018). https://doi.org/10.1016/j.ssci.2018.03.005

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yazdi, M. Improving failure mode and effect analysis (FMEA) with consideration of uncertainty handling as an interactive approach. Int J Interact Des Manuf 13, 441–458 (2019). https://doi.org/10.1007/s12008-018-0496-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-018-0496-2