Abstract

Background

Metal wear and corrosion products generated by hip replacements have been linked to adverse local tissue reactions. Recent investigations of the stem/head taper junction have identified this modular interface as another possible source of metal debris; however, little is known regarding other modular metallic interfaces, their ability to produce metal debris, and possibly to provide insight in the mechanisms that produce metal debris.

Questions/purposes

We asked three questions: (1) can we develop a reliable method to estimate volumetric material loss from the backside taper of modular metal-on-metal liners, (2) do backside tapers of modular metal-on-metal liners show a quantifiable volumetric material loss, and, if so, (3) how do regions of quantitatively identified material loss correspond to visual and microscopic investigations of surface damage?

Methods

Twenty-one cobalt-chromium (CoCr) liners of one design and manufacturer were collected through an institutional review board-approved retrieval program. All liners were collected during revision surgeries, where the primary revision reason was loosening (n = 11). A roundness machine measured 144 axial profiles equally spaced about the circumference of the taper region near the rim to estimate volume and depth of material loss. Sensitivity and repeatability analyses were performed. Additionally, visual and scanning electron microscopy investigations were done for three liners.

Results

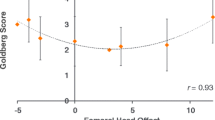

Our measurement method was found to be reproducible. The sensitivity (how dependent measurement results are on experimental parameters) and repeatability (how consistent results are between measurements) analyses confirmed that component alignment had no apparent effect (weak correlation, R2 = 0.04) on estimated volumetric material loss calculations. Liners were shown to have a quantifiable material loss (maximum = 1.7 mm3). Visual investigations of the liner surface could identify pristine surfaces as as-manufactured regions, but could misidentify discoloration as a possible region of material loss. Scanning electron microscopy more accurately distinguished between as-manufactured and damaged regions of the taper.

Conclusions

The roundness machine has been used to develop a repeatable method for characterizing material loss; future work comparing a gravimetric standard with estimations of material loss determined from the roundness machine may show the accuracy and effectiveness of this method. Liners show rates of material loss that compare with those reported for other taper junctions. Visual inspection alone may misidentify as-manufactured regions as regions of material loss.

Clinical relevance

This study identifies the acetabular liner/shell interface in modular metal-on-metal devices as a potential source of metal wear or corrosion products. The relation between metal debris and clinical performance, regardless of the type of bearing couple, is a concern for clinicians. Therefore, it is important to characterize every type of modular junction to understand the quantity, location, and mechanism(s) of material loss.

Similar content being viewed by others

References

Bishop N, Witt F, Pourzal R, Fischer A, Rütschi M, Michel M, Morlock M. Wear patterns of taper connections in retrieved large diameter metal‐on‐metal bearings. J Orthop Res. 2013;31:1116–1122.

Dunbar MJ. The proximal modular neck in THA: a bridge too far: affirms. Orthopedics. 2010;33:640.

Goldberg JR, Gilbert JL, Jacobs JJ, Bauer TW, Paprosky W, Leurgans S. A multicenter retrieval study of the taper interfaces of modular hip prostheses. Clin Orthop Relat Res. 2002;401:149–161.

Higgs GB, Hanzlik JA, MacDonald DW, Gilbert JL, Rimnac CM, Kurtz SM; Implant Research Center Writing Committee. Is increased modularity associated with increased fretting and corrosion damage in metal-on-metal total hip arthroplasty devices?: a retrieval study. J Arthroplasty. 2013;28(8 suppl):2–6.

Higgs GB, Hanzlik JA, MacDonald DW, Kane WM, Day JS, Klein GR, Parvizi J, Mont MA, Kraay MJ, Martell JM, Gilbert JL, Rimnac CM, Kurtz SM. Method of characterizing fretting and corrosion at the various taper connections of retrieved modular components from metal-on-metal total hip arthroplasty. In Kurtz SM, Greenwald AS, Mihalko WM, Lemons J, eds. Selected Technical Papers 1560: Metal-on-Metal Total Hip Replacement Devices. West Conshohocken, PA: ASTM International; 2013: 146–156.

Jacobs JJ, Gilbert JL, Urban RM. Current concepts review: corrosion of metal orthopaedic implants. J Bone Joint Surg Am. 1998;80:268–282.

Krieg A, Speth B, Ochsner P. Backside volumetric change in the polyethylene of uncemented acetabular components. J Bone Joint Surg Br. 2009;91:1037–1043.

Kurtz SM, Ochoa JA, Hovey CB, White CV. Simulation of initial frontside and backside wear rates in a modular acetabular component with multiple screw holes. J Biomech. 1999;32:967–976.

Kwon YM, Glyn-Jones S, Simpson DJ, Kamali A, McLardy-Smith P, Gill HS, Murray DW. Analysis of wear of retrieved metal-on-metal hip resurfacing implants revised due to pseudotumours. J Bone Joint Surg Br. 2010;92:356–361.

Langton DJ, Jameson SS, Joyce TJ, Gandhi JN, Sidaginamale R, Mereddy P, Lord J, Nargol AV. Accelerating failure rate of the ASR total hip replacement. J Bone Joint Surg Br. 2011;93:1011–1016.

Langton DJ, Sidaginamale R, Lord JK, Nargol AV, Joyce TJ. Taper junction failure in large-diameter metal-on-metal bearings. Bone Joint Res. 2012;1:56–63.

Matthies AK, Racasan R, Bills P, Blunt L, Cro S, Panagiotidou A, Blunn G, Skinner J, Hart AJ. Material loss at the taper junction of retrieved large head metal‐on‐metal total hip replacements. J Orthop Res. 2013;31:1677–1685.

Morlock MM, Bishop N, Zustin J, Hahn M, Rüther W, Amling M. Modes of implant failure after hip resurfacing: morphological and wear analysis of 267 retrieval specimens. J Bone Joint Surg Am. 2008;90(suppl 3):89–95.

14. Nassif NA, Nawabi DH, Stoner K, Elpers M, Wright T, Padgett DE. Taper design affects failure of large-head metal-on-metal total hip replacements. Clin Orthop Relat Res. 2014;472:564–571.

Schmalzried TP, Jasty M, Harris WH. Periprosthetic bone loss in total hip arthroplasty: polyethylene wear debris and the concept of the effective joint space. J Bone Joint Surg Am. 1992;74:849–863.

Young AM, Sychterz CJ, Hopper RH Jr, Engh CA. Effect of acetabular modularity on polyethylene wear and osteolysis in total hip arthroplasty. J Bone Joint Surg Am. 2002;84:58–63.

Zahiri CA, Schmalzried TP, Szuszczewicz ES, Amstutz HC. Assessing activity in joint replacement patients. J Arthroplasty. 1998;13:890–895.

Author information

Authors and Affiliations

Corresponding author

Additional information

Institutional funding has been received from the National Institutes of Health (NIAMS) R01 AR47904 (MA, RU, SK, DM, JD, SMK); CeramTec (Plochingen, Germany) (MA, RU, SK, DM, JD, SMK, JP); Stryker Orthopaedics (Mahwah, NJ, USA) (MA, RU, SK, DM, JD, SMK, JP, MM); Zimmer, Inc (Warsaw, IN, USA) (MA, RU, SK, DM, JD, SMK, JP, GK, HC); Celanese (Florence, KY, USA) (MA, RU, SK, DM, JD, SMK); Formae (Paoli, PA, USA) (MA, RU, SK, DM, JD, SMK); Invibio (Lancashire, UK) (MA, RU, SK, DM, JD, SMK); Stelkast (McMurray, PA, USA) (MA, RU, SK, DM, JD, SMK, JP); Aesculap/B.Braun (Center Valley, PA, USA) (MA, RU, SK, DM, JD, SMK); Biomet (Warsaw, IN, USA) (RU, JD, SMK); DePuy Synthes (Warsaw, IN, USA) (RU, JD, SMK, JP); Medtronic (Minneapolis, MN, USA) (RU, JD, SMK); Kyocera Medical (Yodogawa-ku, Osaka, Japan) (RU, JD, SMK); Wright Medical Technology (Arlington, TN, USA) (RU, JD, SMK, MM); DJO (Vista, CA, USA) (RU, JD, SMK, MM); Active Implants (Memphis, TN, USA) (RU, JD, SMK); Smith & Nephew (Memphis, TN, USA) (RU, JD, SMK, JP, HC); Spinal Motion (Mountain View, CA, USA) (RU, JD, SMK); 3 M (Saint Paul, MN, USA) (JP); Joint Active Systems (Effingham, IL, USA) (MM).

One of the authors certifies that he (JP) has received or may receive payments or benefits, during the study period, an amount of USD 10,000 to 100,000 from Smith & Nephew (Memphis, TN, USA) an amount of USD 10,000 to 100,000 from 3 M (Saint Paul, MN, USA), an amount of USD 10,000 to 100,000 from Cadence Pharmaceuticals, Inc (San Diego, CA, USA), an amount of USD 10,000 to 100,000 from CeramTec (Laurens, SC, USA), an amount of USD 10,000 to 100,000 from Pfizer (New York, NY, USA), an amount of USD 10,000 to 100,000 from Salient Surgical (Minneapolis, MN, USA), an amount of USD 10,000 to 100,000 from TissueGene (Rockville, MD, USA), and an amount of USD 10,000 to 100,000 from Zimmer Inc (Warsaw, IN, USA).

One of the authors certifies that he (MM) has received or may receive payments, during the study period, an amount of USD 100,000 to USD 1,000,000 from Stryker Orthopaedics (Mahwah, NJ, USA), an amount of USD 10,000 to USD 100,000 from DJ Orthopaedics (Vista, CA, USA), an amount of USD 10,000 to USD 100,000 from Medical Compression Systems (West Hills, CA, USA), an amount of USD 10,000 to USD 100,000 from Sage Products LLC (Cary, IL, USA), and an amount of USD 10,000 to USD 100,000 from TissueGene (Rockville, MD, USA).

One of the authors certifies that he (GK) has received or may receive payments, during the study period, an amount of USD 10,000 to USD 100,000 from Zimmer, Inc (Warsaw, IN, USA).

One of the authors certifies that he (HC) has received or may receive payments, during the study period, an amount of USD 10,000 to USD 100,000 from Zimmer, Inc (Warsaw, IN, USA), an amount of USD 10,000 to USD 100,000 from Zimmer, Inc (Warsaw, IN, USA), an amount of USD 10,000 to USD 100,000 from Stryker Orthopaedics (Mahwah, NJ, USA), an amount of USD 10,000 to USD 100,000 from Smith & Nephew (Memphis, TN, USA).

All ICMJE Conflict of Interest Forms for authors and Clinical Orthopaedics and Related Research editors and board members are on file with the publication and can be viewed on request.

Each author certifies that his or her institution approved the human protocol for this investigation, that all investigations were conducted in conformity with ethical principles of research, and that informed consent for participation in the study was obtained.

Clinical Orthopaedics and Related Research neither advocates nor endorses the use of any treatment, drug, or device. Readers are encouraged to always seek additional information, including FDA-approval status, of any drug or device prior to clinical use.

This work was performed at the Implant Research Center, Drexel University, Philadelphia, PA, USA.

About this article

Cite this article

Agne, M.T., Underwood, R.J., Kocagoz, S.B. et al. Is There Material Loss at the Backside Taper in Modular CoCr Acetabular Liners?. Clin Orthop Relat Res 473, 275–285 (2015). https://doi.org/10.1007/s11999-014-3982-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11999-014-3982-2