Abstract

Background

Crosslinked UHMWPE as a bearing surface in total joint arthroplasty has higher wear resistance than conventional UHMWPE but lower strength and toughness. To produce crosslinked UHMWPE with improved mechanical properties, the material can be treated before crosslinking by tension to induce molecular alignment (texture).

Questions/purposes

We asked how (1) the microstructure of UHMWPE evolves when subjected to tension and (2) whether the new microstructure (texture) increases strength and toughness.

Methods

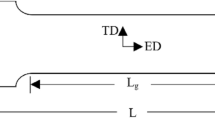

We analyzed microstructure evolution of UHMWPE by small- and wide-angle xray scattering and scanning electron microscopy. We then developed a method to characterize the local strength and toughness of undeformed and textured UHMWPEs by means of nanoscratch tests along and perpendicular to the specimen axis. In three samples we determined the scratch characteristics in terms of deformation mode, coefficient of friction (μ), and viscoelastic recovery (r).

Results

Before the tensile process, the scratch behavior of UHMWPE was characterized by a μ ranging from 0.64 to 0.68, no cracking, and r ranging from 0.58 to 0.60. Microfibrillar morphologic features resulted from the tensile process. The new microstructure had an increased strength (r = 0.78) and decreased toughness (cracking + μ = 0.77) perpendicular to the fibril axis and decreased strength (r = 0.53) and increased toughness (no cracking + μ = 0.55) parallel to the fibril axis.

Conclusions

Textured UHMWPE behaves like a fiber composite with high strength and toughness in well-defined directions. However, the effect of crosslinking on these specific properties is unknown and therefore it is important to verify that the properties are retained. If wear resistance of crosslinked-textured UHMWPE is at least as high as that of crosslinked UHMWPE, novel medical devices made of crosslinked-textured UHMWPE could be developed and clinically tested.

Similar content being viewed by others

References

Addiego F, Dahoun A, G’Sell C, Hiver JM. Characterization of volume strain at large deformation under uniaxial tension in high-density polyethylene. Polymer. 2006;47:4387–4399.

Addiego F, Dahoun A, G’Sell C, Hiver JM, Godard O. Effect of microstructure on crazing onset in polyethylene under tension. Polym Eng Sci. 2009;49:1198–1205.

Ahzi S, Parks DM, Argon AS. Modeling of plastic deformation and evolution of anisotropy in semi-crystalline polymers. In: Singh B, Im YT, Haque I, Altan C, eds. Computer Modeling and Simulation of Manufacturing Processes. New York, NY: ASME; 1990;20:287–292.

Amstutz HC, Campbell P, Kossovsky N, Clarke IC. Mechanism and clinical significance of wear debris-induced osteolysis. Clin Orthop Relat Res. 1992;276:7–18.

Bell CJ, Walker PS, Abeysundera MR, Simmons JM, King PM, Blunn GW. Effect of oxidation on delamination of ultrahigh-molecular-weight polyethylene tibial components. J Arthroplasty. 1998;13:280–290.

Boontongkong Y, Cohen RE, Spector M, Bellare A. Orientation of plan strain-compressed ultra-high-molecular-weight polyethylene. Polymer. 1998;39:6391–6400.

Bowden FP, Tabor D. The Friction and Lubrication of Solids. London, England: Oxford University Press; 1950.

Briscoe BJ, Pelillo E, Sinha SK, Evans PD. Scratching maps for polymers. Wear. 1996;200:137–147.

Cooper RA, McAllister CM, Borden LS, Bauer TW. Polyethylene debris-induced osteolysis and loosening in uncemented total hip arthroplasty: a cause of late failure. J Arthroplasty. 1992;7:285–290.

Fisher J, Jennings LM, Galvin AL, Jin ZM, Stone MH, Ingham E. 2009 Knee Society Presidential Guest Lecture: Polyethylene wear in total knees. Clin Orthop Relat Res. 2010;468:12–18.

Galeski A. Strength and toughness of crystalline polymer systems. Prog Polym Sci. 2003;28:1643–1699.

Gao P, Mackley MR, Nicholson TM. Development of anisotropy in ultra-high molecular weight polyethylene. Polymer. 1990;31:237–242.

Gauthier C, Schirrer R. Time and temperature dependence of the scratch properties of poly(methylmethacrylate) surfaces. J Mater Sci. 2000;35:2121–2130.

Gencur SJ, Rimnac CM, Kurtz SM. Fatigue crack propagation resistance of virgin and highly crosslinked, thermally treated ultra-high molecular weight polyethylene. Biomaterials. 2006;27:1550–1557.

Gul RM, McGarry FJ. Processing of ultra-high molecular weight polyethylene by hot isostatic pressing, and the effect of processing parameters on its microstructure. Polym Eng Sci. 2004;44:1848–1857.

Jardret V, Morel P. Viscoelastic effects on the scratch resistance of polymers: relationship between mechanical properties and scratch properties at various temperatures. Prog Org Coat. 2003;48:322–331.

Kestenbach HJ, Petermann J. Plastic deformation of thin films of ultra-high-molecular- weight polyethylene. Polymer. 1994;35:5217–5224.

Li DS, Garmestani H, Ahzi S, Khaleel M, Ruch D. Microstructure design to improve wear resistance in bioimplant UHMWPE materials. J Eng Mater Technol. 2009;131(04):041211.

Manley MT, Serekian P. Wear debris: an environmental issue in total joint replacement. Clin Orthop Relat Res. 1994;298:137–146.

Marrs H, Barton DC, Doyle C, Jones RA, Lewis EL, Ward IM, Fisher J. The effect of molecular orientation and acethylene-enhanced crosslinking on the wear of UHMWPE in total artificial joints. J Mater Sci Mater Med. 2001;12:621–628.

Miller K, Ramani K. Process-induced residual stresses in compression molded UHMWPE. Polym Eng Sci. 1999;39:110–118.

Ohta M, Hyon SH, Tsutumi S. Control of crystalline orientation to enhance the wear resistance of ultra-high molecular weight polyethylene crystallization cups for artificial joints. Wear. 2003;255:1045–1050.

Olley RH, Basset DC. An improved permanganic etchant for polyolefines. Polymer. 1982;23:1707–1710.

Pruitt LA. Deformation, yielding, fracture and fatigue behavior of conventional and highly cross-linked ultra high molecular weight polyethylene. Biomaterials. 2005;26:905–915.

Schmitt S. TEM analysis of microstructural morphology in ultra high molecular weight polyethylene. Scripta Mater. 2000;43:523–528.

Turell MB, Bellare A. A study of the nanostructure and tensile properties of ultra-high molecular weight polyethylene. Biomaterials. 2004;25:3389–3398.

Wang A, Sun DC, Stark C, Dumbleton JH. Wear mechanisms of UHMWPE in total joint replacements. Wear. 1995;181–183:241–249.

Wang A, Sun DC, Yau S-S, Edwards B, Sokol M, Essner A, Polineni VK, Stark C, Dumbleton JH. Orientation softening in the deformation and wear of ultra-high molecular weight polyethylene. Wear. 1997;203–204:230–241.

Acknowledgments

We thank Mr. D. Murena from Ticona Benelux (Bruxelles, Belgium) for providing UHMWPE. We also express special thanks to Digital Surf Company (Besançon, France) for the use of the software Mountains Maps. Our special thanks go to Prof H. Garmestani and Dr. D. Li from Georgia Institute of Technology (Atlanta, GA) for their involvement and help with this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Each author certifies that he or she has no commercial associations (eg, consultancies, stock ownership, equity interest, or patent/licensing arrangements, etc) that might pose a conflict of interest in connection with the submitted article.

Each author certifies that his or her institution either has waived or does not require approval for the human protocol for this investigation and that all investigations were conducted in conformity with ethical principles of research.

This work was performed at Public Research Centre Henri Tudor, Esch-sur-Alzette, Luxembourg, and Institut Jean Lamour, Nancy, France.

About this article

Cite this article

Addiego, F., Buchheit, O., Ruch, D. et al. Does Texturing of UHMWPE Increase Strength and Toughness?: A Pilot Study. Clin Orthop Relat Res 469, 2318–2326 (2011). https://doi.org/10.1007/s11999-010-1716-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11999-010-1716-7