Abstract

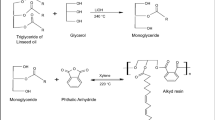

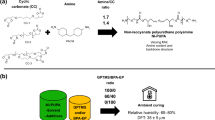

Preparation of ambient and UV curing non-isocyanate polyurethane (NIPU) coatings has been reported using a series of acetoacetylated non-isocyanate polyurethane (AA-NI-PUPO) oligomers. Synthesized oligomers were characterized using various techniques such as Fourier transform infrared and nuclear magnetic resonance spectroscopy. AA-NI-PUPOs showed significantly lower viscosity compared to their non-acetoacetylated counterparts. Ambient temperature-cured systems were formulated by mixing AA-NI-PUPOs and different primary amine compounds in stoichiometric proportions. Michael addition reaction of acrylates and AA-NI-PUPOs was initiated by UV curing using a photobase generator as the catalyst. NIPU coatings were studied for various thermo-mechanical properties and corrosion resistance. The selected UV-cured and ambient-cured samples showed instant and 1-h tack-free time, respectively. Results revealed that with proper selection of acetoacetylated resin and crosslinker type, coatings with properties comparable to conventional PU coatings could be formulated. Moreover, UV-curable coatings with up to 90 wt% solid could be formulated using conventional monomeric acrylates as a reactive diluent. The study demonstrates the feasibility of formulating solvent-free rapid ambient curing non-isocyanate polyurethane coatings.

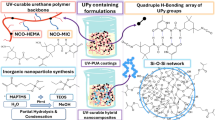

Graphic abstract

Similar content being viewed by others

References

Huang, S, Liu, G, Zhang, K, Hu, H, Wang, J, Miao, L, Tabrizizadeh, T, “Water-Based Polyurethane Formulations for Robust Superhydrophobic Fabrics.” Chem. Eng. J., 360 445–451 (2019). https://doi.org/10.1016/j.cej.2018.11.220

Lambourne, R, Strivens, TA, Paint and Surface Coatings: Theory and Practice. Woodhead Publishing, Cambridge (1999)

Rossi, G, Fuchs, PFJ, Barnoud, J, Monticelli, L, “A Coarse-Grained MARTINI Model of Polyethylene Glycol and of Polyoxyethylene Alkyl Ether Surfactants.” J. Phys. Chem. B., 116 14353–14362 (2012). https://doi.org/10.1021/jp3095165

Hirayama, T, Urban, MW, “Distribution of Melamine in Melamine/Polyester Coatings: FT-IR Spectroscopic Studies.” Prog. Org. Coat., 20 81–96 (1992). https://doi.org/10.1016/0033-0655(92)85006-H

Kong, X, Liu, G, Curtis, JM, “Novel Polyurethane Produced from Canola Oil Based Poly(ether ester) Polyols: Synthesis, Characterization and Properties.” Eur. Polym. J., 48 2097–2106 (2012). https://doi.org/10.1016/j.eurpolymj.2012.08.012

Greunz, T, Lowe, C, Bradt, E, Hild, S, Strauß, B, Stifter, D, “A Study on the Depth Distribution of Melamine in Polyester-Melamine Clear Coats.” Prog. Org. Coat., 115 130–137 (2018). https://doi.org/10.1016/j.porgcoat.2017.11.014

Nelson, TJ, Masaki, B, Morseth, Z, Webster, DC, “Highly Functional Biobased Polyols and Their Use in Melamine–Formaldehyde Coatings.” J. Coat. Technol. Res., 10 757–767 (2013). https://doi.org/10.1007/s11998-013-9524-0

Zamani, E, Yahyaei, H, Khosravi, A, Mohseni, M, Shaki, H, “Synthesis and Characterization of a Novel Self-colored Fluorescent Polycarbonate Urethane Based on the 1,8-Naphthalimide Group.” J. Macromol. Sci. Part B, 58 772–781 (2019). https://doi.org/10.1080/00222348.2019.1635726

Mahmudzadeh, M, Yari, H, Ramezanzadeh, B, Mahdavian, M, “Urtica Dioica Extract as a Facile Green Reductant of Graphene Oxide for UV Resistant and Corrosion Protective Polyurethane Coating Fabrication.” J. Ind. Eng. Chem., 78 125–136 (2019). https://doi.org/10.1016/j.jiec.2019.06.026

Wexler, P, Anderson, BD, Encyclopedia of Toxicology. Elsevier Science Direct, Amsterdam (2005)

Wang, P, Liu, S, Deng, Y, “Important Green Chemistry and Catalysis: Non-phosgene Syntheses of Isocyanates-Thermal Cracking Way.” Chin. J. Chem., 35 821–835 (2017). https://doi.org/10.1002/cjoc.201600745

Zhu, HD, Kneisel, AR, Mahdi, SZ, Saracsan, JW, “Low Volatile Isocyanate Monomer Containing Polyurethane Prepolymer and Adhesive System,” WO2006042305A1, 2006. https://patents.google.com/patent/WO2006042305A1/en.

OSHA Announces New National Emphasis Program for Occupational Exposure to Isocyanates | Occupational Safety and Health Administration. https://www.osha.gov/news/newsreleases/trade/06252013.

Deepa, P, Jayakannan, M, “Solvent-Free and Nonisocyanate Melt Transurethane Reaction for Aliphatic Polyurethanes and Mechanistic Aspects.” J. Polym. Sci. Part Polym. Chem., 46 2445–2458 (2008). https://doi.org/10.1002/pola.22578

Kušan, J, Keul, H, Höcker, H, “Cationic Ring-Opening Polymerization of Tetramethylene Urethane.” Macromolecules, 34 389–395 (2001). https://doi.org/10.1021/ma000535c

Kathalewar, MS, Joshi, PB, Sabnis, AS, Malshe, VC, “Non-isocyanate Polyurethanes: from Chemistry to Applications.” RSC Adv., 3 4110–4129 (2013). https://doi.org/10.1039/C2RA21938G

Figovsky, O, Leykin, A, “Synthesis and Application of Nonisocyanate Polyurethanes.” Chem. Chem. Technol., 10 553–559 (2016). https://doi.org/10.23939/chcht10.04si.553

Rokicki, G, Parzuchowski, PG, Mazurek, M, “Non-isocyanate Polyurethanes: Synthesis, Properties, and Applications.” Polym. Adv. Technol., 26 707–761 (2015). https://doi.org/10.1002/pat.3522

Blattmann, H, Fleischer, M, Bähr, M, Mülhaupt, R, “Isocyanate- and Phosgene-Free Routes to Polyfunctional Cyclic Carbonates and Green Polyurethanes by Fixation of Carbon Dioxide.” Macromol. Rapid Commun., 35 1238–1254 (2014). https://doi.org/10.1002/marc.201400209

Ghasemlou, M, Daver, F, Ivanova, EP, Adhikari, B, “Bio-based Routes to Synthesize Cyclic Carbonates and Polyamines Precursors of Non-Isocyanate Polyurethanes: A Review.” Eur. Polym. J., 118 668–684 (2019). https://doi.org/10.1016/j.eurpolymj.2019.06.032

Yu, AZ, Setien, RA, Sahouani, JM, Docken, J, Webster, DC, “Catalyzed Non-isocyanate Polyurethane (NIPU) Coatings from Bio-based Poly(cyclic carbonates).” J. Coat. Technol. Res., 16 41–57 (2019). https://doi.org/10.1007/s11998-018-0135-7

Wu, Z, Tang, L, Dai, J, Qu, J, “Synthesis and Properties of Fluorinated Non-isocyanate Polyurethanes Coatings with Good Hydrophobic and Oleophobic Properties.” J. Coat. Technol. Res., 16 1233–1241 (2019). https://doi.org/10.1007/s11998-019-00195-5

Aoyagi, N, Furusho, Y, Endo, T, “Effective Synthesis of Cyclic Carbonates from Carbon Dioxide and Epoxides by Phosphonium Iodides as Catalysts in Alcoholic Solvents.” Tetrahedron. Lett., 54 7031–7034 (2013). https://doi.org/10.1016/j.tetlet.2013.10.068

Wu, Y, Song, X, Li, S, Zhang, J, Yang, X, Shen, P, Gao, L, Wei, R, Zhang, J, Xiao, G, “3D-Monoclinic M-BTC MOF (M = Mn Co, Ni) as Highly Efficient Catalysts for Chemical Fixation of CO2 into Cyclic Carbonates.” J. Ind. Eng. Chem., 58 296–303 (2018). https://doi.org/10.1016/j.jiec.2017.09.040

Figovsky, OL, Shapovalov, L, Leykin, A, Birukova, O, Potashnikova, R, “Progress in Elaboration of Nonisocyanate Polyurethanes Based on Cyclic Carbonates.” Int. Lett. Chem. Phys. Astron., 3 52–66 (2013). https://doi.org/10.18052/www.scipress.com/ILCPA.3.52

Wazarkar, K, Kathalewar, M, Sabnis, A, “Development of Epoxy-Urethane Hybrid Coatings Via Non-isocyanate Route.” Eur. Polym. J., 84 812–827 (2016). https://doi.org/10.1016/j.eurpolymj.2016.10.021

Byczyński, Ł, Dutkiewicz, M, Maciejewski, H, “Synthesis and Properties of High-solids Hybrid Materials Obtained from Epoxy Functional Urethanes and Siloxanes.” Prog. Org. Coat., 84 59–69 (2015). https://doi.org/10.1016/j.porgcoat.2015.02.017

Kathalewar, M, Sabnis, A, “Preparation of Novel CNSL-Based Urethane Polyol Via Nonisocyanate Route: Curing with Melamine-Formaldehyde Resin and Structure-Property Relationship,” J. Appl. Polym. Sci., 132 (2015) n/a-n/a. https://doi.org/10.1002/app.41391.

Ecochard, Y, Leroux, J, Boutevin, B, Auvergne, R, Caillol, S, “From Multi-functional Siloxane-Based Cyclic Carbonates to Hybrid Polyhydroxyurethane Thermosets.” Eur. Polym. J., 120 109280 (2019). https://doi.org/10.1016/j.eurpolymj.2019.109280

Asemani, H, Zareanshahraki, F, Mannari, V, “Design of Hybrid Nonisocyanate Polyurethane Coatings for Advanced Ambient Temperature Curing Applications.” J. Appl. Polym. Sci., 136 47266 (2019). https://doi.org/10.1002/app.47266

Zareanshahraki, F, Asemani, HR, Skuza, J, Mannari, V, “Synthesis of Non-isocyanate Polyurethanes and Their Application in Radiation-Curable Aerospace Coatings.” Prog. Org. Coat., 138 105394 (2020). https://doi.org/10.1016/j.porgcoat.2019.105394

Asemani, HR, Mannari, V, “Synthesis and Evaluation of Non-isocyanate Polyurethane Polyols for Heat-cured Thermoset Coatings.” Prog. Org. Coat., 131 247–258 (2019). https://doi.org/10.1016/j.porgcoat.2019.02.036

Chattopadhyay, DK, Raju, KVSN, “Structural Engineering of Polyurethane Coatings for High Performance Applications.” Prog. Polym. Sci., 32 352–418 (2007). https://doi.org/10.1016/j.progpolymsci.2006.05.003

Noomen, A, “Applications of Michael Addition Chemistry in Coatings Technology.” Prog. Org. Coat., 32 137–142 (1997). https://doi.org/10.1016/S0300-9440(97)00070-2

Kuo, T, Grosso, PV, Spilman, GE, Clark, MD, “Fast-dry, High Solids Coating Compositions Based on Acetoacetate-Functionalized Alkyd Resins,” US6794049B2, 2004. https://patents.google.com/patent/US6794049/en.

Narayan, R, Chattopadhyay, DK, Sreedhar, B, Raju, KVSN, “Cure, Viscoelastic and Mechanical Properties of Hydroxylated Polyester Melamine High Solids Coatings.” J. Mater. Sci., 37 4911–4918 (2002). https://doi.org/10.1023/A:1020834818562

Narayan, R, Raju, KVSN, “Properties of Acetoacetylated Hydroxylated Polyesters Based Polyurethane Coatings.” Prog. Org. Coat., 45 59–67 (2002). https://doi.org/10.1016/S0300-9440(02)00116-9

Paramarta, A, Webster, DC, “The Exploration of Michael-Addition Reaction Chemistry to Create High Performance, Ambient Cure Thermoset Coatings Based on Soybean Oil.” Prog. Org. Coat., 108 59–67 (2017). https://doi.org/10.1016/j.porgcoat.2017.04.004

Mohajeri, S, Burke, NAD, Stöver, HDH, “The Stability of Enamine Crosslinks Formed from Acetoacetate/Amine in Synthetic Hydrogels.” Polym. Degrad. Stab., 114 94–104 (2015). https://doi.org/10.1016/j.polymdegradstab.2015.01.027

Manchanda, H, Mannari, V, “Super Photo-base Initiated Organic–Inorganic Hybrid Coatings by Plural-cure Mechanisms.” Prog. Org. Coat., 127 222–230 (2019). https://doi.org/10.1016/j.porgcoat.2018.11.011

Pilehkouhi, M, Shaki, H, Khosravi, A, Khorasani, M, Zamani, E, “Synthesis and Characterization of a Fluorescent Water-Borne Polyurethane Based on a Novel Naphthalimide Dye.” J. Macromol. Sci. Part B., 57 151–167 (2018). https://doi.org/10.1080/00222348.2018.1435501

Krall, EM, Serum, EM, Sibi, MP, Webster, DC, “Catalyst-free Lignin Valorization by Acetoacetylation. Structural Elucidation by Comparison with Model Compounds.” Green Chem., 20 2959–2966 (2018). https://doi.org/10.1039/C8GC01071D

Cao, Z, Gao, F, Zhao, J, Wei, X, Cheng, Q, Zhong, J, Lin, C, Shu, J, Fu, C, Shen, L, “Bio-based Coating Materials Derived from Acetoacetylated Soybean Oil and Aromatic Dicarboxaldehydes.” Polymers, 11 1809 (2019). https://doi.org/10.3390/polym11111809

Tucker, HA, “Fast-curing, High Strength, Two-Part Sealants Using Acetoacetate-Amine Cure Chemistry,” EP0603716A1, 1994. https://patents.google.com/patent/EP0603716A1/en.

Eastman t-BAA (Tertiary-Butyl acetoacetate) for the Synthesis of Acetoacetyl-Functional Resins. https://www.eastman.com/Literature_Center/N/N328.pdf.

Konuray, AO, Ruiz, A, Morancho, JM, Salla, JM, Fernández-Francos, X, Serra, À, Ramis, X, “Sequential Dual Curing by Selective Michael Addition and Free Radical Polymerization of Acetoacetate-Acrylate-Methacrylate Mixtures.” Eur. Polym. J., 98 39–46 (2018). https://doi.org/10.1016/j.eurpolymj.2017.11.003

Urdl, K, Kandelbauer, A, Kern, W, Müller, U, Thebault, M, Zikulnig-Rusch, E, “Self-healing of Densely Crosslinked Thermoset Polymers—A Critical Review.” Prog. Org. Coat., 104 232–249 (2017). https://doi.org/10.1016/j.porgcoat.2016.11.010

Asemani, HR, Sarabi, AA, Eivaz Mohammadloo, H, Sarayloo, M, “Electrochemical and Morphological Properties of Zirconium Conversion Coating in the Presence of Nickel Ions on Galvanized Steel.” J. Coat. Technol. Res., 13 883–894 (2016). https://doi.org/10.1007/s11998-016-9800-x

Acknowledgments

The authors would like to gratefully acknowledge financial support from the federal agency—strategic environmental research and development program (SERDP), USA.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Asemani, H.R., Mannari, V. Ambient temperature and UV-cured hybrid coatings from acetoacetylated non-isocyanate polyurethanes. J Coat Technol Res 18, 469–488 (2021). https://doi.org/10.1007/s11998-020-00425-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-020-00425-1