Abstract

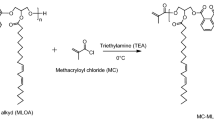

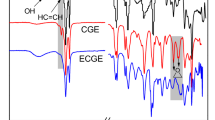

Two non-isocyanate polyurethanes (NIPUs) were used as reactive diluents for an alkyd to obtain eco-friendly new UV-curable alkyd-polyurethane coatings. A linseed-based alkyd resin was prepared and formulated with the reactive diluents (NIPUs) and free radical photoinitiator, and then UV-cured. NMRs were used to characterize the alkyd and NIPUs and glass transition temperature (Tg) of cured alkyd-polyurethanes were evaluated by using DSC. Further, spectroscopy and thermal stability of the coatings were evaluated by using ATR-IR spectroscopy and thermogravimetric analysis (TGA), respectively. Moreover, coating properties such as pencil hardness, cross-cut adhesion, pull-off adhesion, impact resistance, and reverse impact resistance were also evaluated. It was found that crosslink density, pencil hardness, adhesion, and Tg were dependent and proportional to the amount of the NIPUs (reactive diluents) showing significant improvement in mechanical and thermal properties compared to the linseed-based alkyd resin.

Similar content being viewed by others

References

Cornille, A, Auvergne, R, Figovsky, O, Boutevin, B, Caillol, S, “A Perspective Approach to Sustainable Routes for Non-isocyanate Polyurethanes.” Eur. Polym. J., 87 535–552. https://doi.org/10.1016/j.eurpolymj.2016.11.027 (2017)

Randall, SLD, The Polyurethanes Book. Wiley (2002)

Wirpsza, TJKZ, Polyurethanes: Chemistry, Technology, and Applications. E. Horwood (1993)

Shen, L, Haufe, J, Patel, MK, Report of Utrecht University Commissioned by European Polysaccharide Network of Excellence and European Bioplastics. Utrecht University (2009)

Bernstein, L, “Isocyanate Induced Pulmonary Diseases: A Current Perspective.” J. Allergy Clin. Immunol., 70 24–31 (1982)

Merenyi, S, Regulation (EC) No 1907/2006: Consolidated Version (June 2012) with an Introduction and Future Prospects Regarding the Area of Chemicals Legislation. GRIN Verlag (2012)

Chattopadhyay, DK, Raju, KVSN, “Structural Engineering of Polyurethane Coatings for High Performance Applications.” Prog. Polym. Sci., 32 352–418. https://doi.org/10.1016/j.progpolymsci.2006.05.003 (2007)

Warner, JJ, Wang, P, Mellor, WM, Hwang, HH, Park, JH, Pyo, SH, Chen, S, “3D Printable Non-isocyanate Polyurethanes with Tunable Material Properties.” Polym. Chem., 10 4665–4674. https://doi.org/10.1039/c9py00999j (2019)

Lockey, JE, Redlich, CA, Streicher, R, Pfahles-Hutchens, A, Hakkinen, PJ, Ellison, GL, Harber, P, Utell, M, Holland, J, Comai, A, White, M, “Isocyanates and Human Health: Multistakeholder Information Needs and Research Priorities.” J. Occup. Environ. Med., 57 44–51. https://doi.org/10.1097/JOM.0000000000000278 (2015)

Engels, HW, Pirkl, HG, Albers, R, Albach, RW, Krause, J, Hoffmann, A, Casselmann, H, Dormish, J, “Polyurethanes: Versatile Materials and Sustainable Problem Solvers for Today’s Challenges.” Angew. Chem. Int. Ed., 52 9422–9441. https://doi.org/10.1002/anie.201302766 (2013)

Maisonneuve, L, Lamarzelle, O, Rix, E, Grau, E, Cramail, H, “Isocyanate-Free Routes to Polyurethanes and Poly(hydroxy Urethane)s.” Chem. Rev., 115 12407–12439. https://doi.org/10.1021/acs.chemrev.5b00355 (2015)

Kreye, O, Mutlu, H, Meier, MAR, “Sustainable Routes to Polyurethane Precursors.” Green Chem., 15 1431–1455. https://doi.org/10.1039/c3gc40440d (2013)

Heederik, D, Henneberger, PK, Redlich, CA, “Primary Prevention: Exposure Reduction, Skin Exposure and Respiratory Protection.” Eur. Respir. Rev., 21 112–124. https://doi.org/10.1183/09059180.00005111 (2012)

Ward, AL, Dori, SE, Li, L, Hughes, MA, Qu, X, Persson, KA, Helms, BA, “Materials Genomics Screens for Adaptive Ion Transport Behavior by Redox-Switchable Microporous Polymer Membranes in Lithium-Sulfur Batteries.” ACS Cent. Sci., 3 399–406. https://doi.org/10.1021/acscentsci.7b00012 (2017)

Godfrey, OO, Ifijen, IH, Mohammed, FU, Aigbodion, AI, Ikhuoria, EU, “Alkyd Resin from Rubber Seed Oil/Linseed Oil Blend: A Comparative Study of the Physiochemical Properties.” Heliyon., 5 4. https://doi.org/10.1016/j.heliyon.2019.e01621 (2019)

Keleş, E, Hazer, B, “Synthesis of Segmented Polyurethane Based on Polymeric Soybean Oil Polyol and Poly (Ethylene Glycol).” J. Polym. Environ., 17 153–158. https://doi.org/10.1007/s10924-009-0132-0 (2009)

Alam, M, Akram, D, Sharmin, E, Zafar, F, Ahmad, S, “Vegetable Oil Based Eco-friendly Coating Materials: A Review Article.” Arab. J. Chem., 7 469–479. https://doi.org/10.1016/j.arabjc.2013.12.023 (2014)

Gao, S, Tang, G, Hua, D, Xiong, R, Han, J, Jiang, S, Zhang, Q, Huang, C, “Stimuli-Responsive Bio-based Polymeric Systems and Their Applications.” J. Mater. Chem. B., 7 709–729. https://doi.org/10.1039/c8tb02491j (2019)

Jones, FN, Nichols, ME, Pappas, SP, Organic Coatings, 4th edn. Wiley (2017)

Babahan-bircan, I, Demirkaya, I, Obaid, S, Hasan, H, Thomas, J, Soucek, MD, “Progress in Organic Coatings Comparison of New Bio-based Epoxide-Amine Coatings with Their Nanocomposite Coating Derivatives (Graphene, CNT, and Fullerene) as Replacements for BPA.” Prog. Org. Coat., 165 106714. https://doi.org/10.1016/j.porgcoat.2022.106714 (2022)

Zhang, C, Garrison, TF, Madbouly, SA, Kessler, MR, “Recent Advances in Vegetable Oil-Based Polymers and Their Composites.” Prog. Polym. Sci., 71 91–143. https://doi.org/10.1016/j.progpolymsci.2016.12.009 (2017)

Eromosele, CO, Eromosele, IC, “Fatty Acid Compositions of Seed Oils of Haematostaphis barteri and Ximenia americana.” Bioresour. Technol., 82 303–304. https://doi.org/10.1016/S0960-8524(01)00179-1 (2002)

Abd El-Ghaffar, MA, Youssef, EA, Abo-Shosa, MM, Ibrahim, NA, Articles Modified Alkyd Resin as Binder for Paints. Pigment & Resin Technology (1996)

Wang, X, Soucek, MD, “Investigation of Non-isocyanate Urethane Dimethacrylate Reactive Diluents for UV-Curable Polyurethane Coatings.” Prog. Org. Coat., 76 1057–1067. https://doi.org/10.1016/j.porgcoat.2013.03.001 (2013)

Fouassier, JP, Morlet-Savary, F, Lalevée, J, Allonas, X, Ley, C, “Dyes as Photoinitiators or Photosensitizers of Polymerization Reactions.” Materials (Basel)., 3 5130–5142. https://doi.org/10.3390/ma3125130 (2010)

Salata, RR, Pellegrene, B, Soucek, MD, “Visible Light Cure Packages for Improved Drying Kinetics in Alkyd Coatings.” Prog. Org. Coat., 144 105672. https://doi.org/10.1016/j.porgcoat.2020.105672 (2020)

Choi, JS, Seo, J, Khan, SB, Jang, ES, Han, H, “Effect of Acrylic Acid on the Physical Properties of UV-Cured Poly(Urethane Acrylate-co-Acrylic Acid) Films for Metal Coating.” Prog. Org. Coat., 71 110–116. https://doi.org/10.1016/j.porgcoat.2011.01.005 (2011)

Patil, DM, Phalak, GA, Mhaske, ST, “Novel Phosphorus-Containing Epoxy Resin from Renewable Resource for Flame-Retardant Coating Applications.” J. Coat. Technol. Res., 16 531–542. https://doi.org/10.1007/s11998-018-0116-x (2019)

Thomas, J, Singh, V, Jain, R, “Synthesis and Characterization of Solvent Free Acrylic Copolymer for Polyurethane Coatings.” Prog. Org. Coat., 145 105677. https://doi.org/10.1016/j.porgcoat.2020.105677 (2020)

Patil, RS, Sancaktar, E, “Fabrication of pH-Responsive Polyimide Polyacrylic Acid Smart Gating Membranes: Ultrafast Method Using 248 nm Krypton Fluoride Excimer Laser.” ACS Appl. Mater. Interfaces, 13 24431–24441. https://doi.org/10.1021/acsami.1c01265 (2021)

Patil, RS, Sancaktar, E, “Effect of Solution Parameters on pH-Response of Polyacrylic Acid Grafted Polyimide Smart Membrane Fabricated Using 248 nm Krypton Fluoride Excimer Laser.” Polymer, 233 124181. https://doi.org/10.1016/j.polymer.2021.124181 (2021)

Oyman, ZO, Towards Environmentally Friendly Catalysts For Alkyd Coatings. Technische Universiteit Eindhoven. https://doi.org/10.6100/IR584358 (2005)

Ren, X, Xu, T, Thomas, J, Soucek, MD, “Isoprene Soya Diels-Alder Adduct and Epoxidation for Photopolymerization.” Macromol. Chem. Phys., 222 1–11. https://doi.org/10.1002/macp.202100054 (2021)

Elba, ME, Abdel Rehim, EM, Ashery, RE, “Synthesis and Characterization of Alkyd Resin Based on Soybean Oil and Glycerin Using Zirconium Octoate as Catalyst.” Int. J. Chem. Technol., 2 34–43. https://doi.org/10.32571/ijct.347670 (2018)

Babahan, I, Zheng, Y, Soucek, MD, “New Bio-based Glycidal Epoxides.” Prog. Org. Coat., 142 105580. https://doi.org/10.1016/j.porgcoat.2020.105580 (2020)

Mayer, P, Dmitruk, A, Jóskiewicz, M, Głuch, M, “Pull-Off Strength of Fiber-Reinforced Composite Polymer Coatings on Aluminum Substrate.” J. Adhes.,. https://doi.org/10.1080/00218464.2020.1771556 (2020)

Mayer, P, “Impact Test of Aged Polymer Coatings on Steel Substrate.” Interdiscip. J. Eng. Sci., VI (1) 1–9 (2018)

Kurniawan, O, Soegijono, B, “Preparation and Characterization of Polyurethane/ Carbon/Organoclay Composite for Coating of Aluminum Conductor Overhead Lines.” Surf. Sci., 18 62–69 (2020)

Black, M, Rawlins, JW, “Thiol-Ene UV-Curable Coatings Using Vegetable Oil Macromonomers.” Eur. Polym. J., 45 1433–1441. https://doi.org/10.1016/j.eurpolymj.2009.02.007 (2009)

Strazisar, S, Kendi, M, Fäcke, T, Hermans-Blackburn, L, Feng, XS, “New High-Throughput Screening Tool for the Evaluation of Pigmented UV-A Curable Coatings: A Case Study Using Low Energy Lamps.” J. Coat. Technol. Res., 3 307–312. https://doi.org/10.1007/s11998-006-0027-0 (2006)

Soucek, MD, Johnson, AH, Wegner, JM, “Ternary Evaluation of UV-Curable Seed Oil Inorganic/Organic Hybrid Coatings Using Experimental Design.” Prog. Org. Coat., 51 300–311. https://doi.org/10.1016/j.porgcoat.2004.07.019 (2004)

Ortiz, RA, López, DP, Cisneros, MDLG, Valverde, JCR, Crivello, JV, “A Kinetic Study of the Acceleration Effect of Substituted Benzyl Alcohols on the Cationic Photopolymerization Rate of Epoxidized Natural Oils.” Polymer (Guildf)., 46 1535–1541. https://doi.org/10.1016/j.polymer.2004.12.020 (2005)

Seniha Güner, F, Yağci, Y, Tuncer Erciyes, A, “Polymers from Triglyceride Oils.” Prog. Polym. Sci., 31 633–670. https://doi.org/10.1016/j.progpolymsci.2006.07.001 (2006)

Ye, G, Courtecuisse, F, Allonas, X, Ley, C, Croutxe-Barghorn, C, Raja, P, Taylor, P, Bescond, G, “Photoassisted Oxypolymerization of Alkyd Resins: Kinetics and Mechanisms.” Prog. Org. Coat., 73 366–373. https://doi.org/10.1016/j.porgcoat.2011.03.015 (2012)

Li, Y, Wang, D, Sun, XS, “Epoxidized and Acrylated Epoxidized Camelina Oils for Ultraviolet-Curable Wood Coatings.” J. Am. Oil Chem. Soc., 95 1307–1318. https://doi.org/10.1002/aocs.12123 (2018)

Haniffa, MACM, Ching, Y-C, Chuah, C-H, Kuan, Y-C, Liu, D-S, Liou, N-S, “Synthesis, Characterization and the Solvent Effects on Interfacial Phenomena of Jatropha Curcas Oil Based Non-Isocyanate Polyurethane.” Polymers, 9 162. https://doi.org/10.3390/polym9050162 (2017)

Silbert, SD, Serum, EM, LaScala, J, Sibi, MP, Webster, DC, “Biobased, Nonisocyanate, 2K Polyurethane Coatings Produced from Polycarbamate and Dialdehyde Cross-linking.” ACS Sustain. Chem. Eng., 7 19621–21963. https://doi.org/10.1021/acssuschemeng.9b04713 (2019)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Babahan-Bircan, I., Thomas, J. & Soucek, M.D. Environment-friendly UV-curable alkyd-based non-isocyanate urethanes. J Coat Technol Res 19, 1507–1522 (2022). https://doi.org/10.1007/s11998-022-00623-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-022-00623-z