Abstract

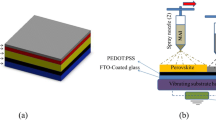

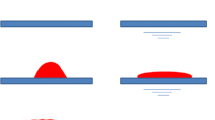

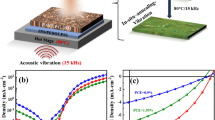

In an attempt to improve surface wetting and coating characteristics, a novel technique, i.e., imposing ultrasonic vibration on the substrate, is introduced. This technique is combined with conventional ultrasonic spray coating, thus substrate vibration-assisted spray coating (SVASC), and is employed to fabricate PEDOT:PSS thin films. PEDOT:PSS is a co-polymer, commonly used as solar cell buffer layers and thin-film electrodes. Advanced surface characterization techniques, such as atomic force microscopy and confocal laser scanning microscopy are utilized. The results show that the application of the imposed vibration on the substrate results in a significant decrease in surface roughness, film thickness, and the number of defects and pin-holes. In terms of the film functionality, the electrical conductivity of the PEDOT:PSS films made using the SVASC technique shows a four-time increase, compared to those made by conventional ultrasonic spray coating. In conventional ultrasonic spray coating, increasing the number of spray passes or deposition layers usually improves the coating uniformity. For aqueous PEDOT:PSS solution and within the range of the values of the parameters investigated in this work, with imposed substrate vibration, the number of spray passes is immaterial, as far as the film uniformity is concerned. However, the application of multiple spray passes enhances the film’s electrical conductivity. Our unprecedented results on the combined substrate vibration with spray coating provide a platform for low-cost fabrication of solution-processed thin-film solar cell devices, and a forward step toward commercialization of emerging solar cells, such as polymer and perovskite solar cells. The positive effect of using imposed substrate vibration on spray-on solar cell thin films may be deployed in other coating (e.g., spin coating) and spray coating applications as well.

Similar content being viewed by others

References

Eslamian, M, “A Mathematical Model for the Design and Fabrication of Polymer Solar Cells by Spray Coating.” Dry. Technol., 31 405–413 (2013)

Ikegawa, M, Azuma, H, “Droplet Behaviors on Substrates in Thin Film Formation Using Ink-Jet Printing.” JSME Int. J. Ser. B, 47 490–496 (2004)

Yule, AJ, Al-Suleimani, Y, “On Droplet Formation from Capillary Waves on a Vibrating Surface.” Proc. R. Soc. Lond. A, 456 1069–1085 (2000)

Eslamian, M, “Spray-On Thin Film PV Solar Cells: Advances, Potentials and Challenges.” Coatings, 4 60–84 (2014)

Zhao, YP, Wang, Y, “Fundamentals and Applications of Electrowetting: A Critical Review.” Rev. Adhes. Adhes., 1 114–174 (2013)

Vukasinovic, B, Smith, MK, Glezer, A, “Mechanisms of Free-Surface Breakup in Vibration-Induced Liquid Atomization.” Phys. Fluids, 19 012104 (2007)

Noblin, X, Kofman, R, Celestini, F, “Ratchet-Like Motion of a Shaken Drop.” Phys. Rev. Lett., 102 194504 (2009)

Daniel, S, Chaudhury, MK, “Rectified Motion of Liquid Drops on Gradient Surfaces Induced by Vibration.” Langmuir, 18 3404–3407 (2002)

Mettu, S, Chaudhury, MK, “Motion of Drops on Surface Induced by Thermal Gradient and Vibration.” Langmuir, 24 10833–10837 (2008)

Lei, W, Jia, Z, He, JC, Cai, TM, “Dynamic Properties of Vibrated Drops on a Superhydrophobic Patterned Surface.” Appl. Thermal Eng., 62 507–512 (2014)

Noblin, X, Buguin, A, Brochard-Wyart, F, “Vibrated Sessile Drops: Transition Between Pinned and Mobile Contact Line Oscillations.” Eur. Phys. J. E, 14 395–404 (2004)

Dong, L, Chaudhury, A, Chaudhury, MK, “Lateral Vibration of a Water Drop and its Motion on a Vibrating Surface.” Eur. Phys. J. E., 21 231–242 (2006)

Whitehill, JD, Neild, A, Stokes, MH, “Forced Spreading Behavior of Droplets Undergoing Low Frequency Vibration.” Colloids Surf. A, 393 144–152 (2012)

Whitehill, J, Neild, A, Ng, TW, Martyn, S, Chong, J, “Droplet Spreading Using Low Frequency Vibration.” Appl. Phys. Lett., 98 133503 (2011)

Whitehill, J, Martyn, S, Neild, A, Ng, TW, “Droplet Behavior Under High Intensity Acoustic Vibration”, Proceedings of 20th International Congress on Acoustics, ICA, Sydney, Australia, August 2010

Brunet, P, Eggers, J, Deegan, RD, “Motion of a Drop Driven by Substrate Vibrations.” Eur. Phys. J. Spec. Top., 166 11–14 (2009)

Fathi, S, Dickens, PM, Hague, RJM, Khodabakhshi, K, Gilbert, M, “Analysis of Droplet Train/Moving Substrate Interactions in Ink-Jetting Processes.” In: Bourell, DL, Crawford, RH, Seepersad, CC, Beaman, JJ, Marcus, H, (eds.) Solid Freeform Fabrication Proceedings, University of Texas at Austin, 230 (2008).

Fathi, S, Dickens, PM, Fouchal, F, “Regimes of Droplet Train Impact on a Moving Surface in an Additive Manufacturing Process.” J. Mater. Process. Technol., 210 550–559 (2010)

Fang, TH, Chang, WJ, Lin, SL, “Effects of Temperature and Velocity of Droplet Ejection Process of Simulated Nanojets onto a Moving Plate’s Surface.” Appl. Surf. Sci., 253 1649–1654 (2006)

Keshavarz, B, Green, SI, Davy, MH, Eadie, DT, “Newtonian Liquid Jet Impaction on a High-Speed Moving Surface.” Int. J. Heat Fluid Flow, 32 1216–1225 (2011)

Dressler, DM, Li, L, Green, SI, Davy, MH, Eadie, DT, “Newtonian and NonNewtonian Spray Interaction with a High Speed Moving Surface.” Atomization Sprays, 19 19–39 (2009)

Oberti, S, Neild, A, Ng, TW, “Microfluidic Mixing under Low Frequency Vibration.” Lab on a Chip, 9 1435–1438 (2009)

Daniel, S, Chaudhury, MK, de Gennes, PG, “Vibration-Actuated Drop Motion on Surfaces for Batch Microfluidic Processes.” Langmuir, 21 4240–4248 (2005)

Alvarez, M, Friend, JR, Yeo, LY, “Surface Vibration Induced Spatial Ordering of Periodic Polymer Patterns on a Substrate.” Langmuir, 24 10629–10632 (2008)

Zabihi, F, Eslamian, M, “Characteristics of Thin Films Fabricated by Spray Coating on Rough and Permeable Paper Substrates.” J. Coat. Technol. Res., (2015). doi:10.1007/s11998-015-9656-5

Zabihi, F, Xie, Y, Gao, S, Eslamian, M, “Morphology, Conductivity and Wetting Characteristics of PEDOT:PSS Thin Films Deposited by Spin and Spray Coating.” Appl. Surf. Sci., 338 163–177 (2015)

Wengeler, L, Peters, K, Schmitt, M, Wenz, T, Scharfer, P, Schabel, W, “Fluid-Dynamic Properties and Wetting Behavior of Coating Inks For Roll-to-Roll Production of Polymer-Based Solar Cells.” J. Coat. Technol. Res., 11 65–73 (2014)

Kim, KJ, Kim, YS, Kang, WS, Kang, BH, Yeom, SH, Kim, DE, Kim, JH, Kang, SW, “Inspection of Substrate-Heated Modified PEDOT:PSS Morphology for All Spray Deposited Organic Photovoltaics.” Sol. Energy Mater. Sol. Cells, 94 1303–1306 (2010)

Kim, YH, Sachse, C, Machala, ML, May, C, Müller-Meskamp, L, Leo, K, “Highly Conductive PEDOT:PSS Electrode with Optimized Solvent and Thermal Post-Treatment for ITO-Free Organic Solar Cells.” Adv. Funct. Mater., 21 1076–1081 (2011)

Kim, N, Kee, S, Lee, SH, Lee, BH, Kahng, YH, Jo, YR, Kim, BJ, Lee, K, “Transparent Electrodes: Highly Conductive PEDOT:PSS Nanofibrils Induced by Solution-Processed Crystallization.” Adv. Mater., 26 2109 (2014)

Acknowledgments

The authors are grateful to Yaping Dan and coworkers from the University of Michigan-Shanghai Jiao Tong University Joint Institute for providing the conductivity analysis test instrument.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zabihi, F., Eslamian, M. Substrate vibration-assisted spray coating (SVASC): significant improvement in nano-structure, uniformity, and conductivity of PEDOT:PSS thin films for organic solar cells. J Coat Technol Res 12, 711–719 (2015). https://doi.org/10.1007/s11998-015-9682-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-015-9682-3