Abstract

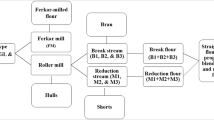

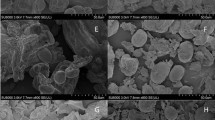

The study evaluates the effect of pulse milling pre-treatments such as moisture conditioning and mechanical scouring on the compositional (moisture, protein, ash), functional (water-holding capacity), and physical (L*a*b* color, particle size distribution) properties of pulse flours. Two different types of pulses of pure cultivars, lentil (Lens culinaris) and chickpea (Cicer arietinum), were milled into flour using a laboratory-scale roller mill. Prior to milling, pulse seeds were subjected to two types of seed pre-treatments—(1) moisture conditioning (0%, 0.5%, or 1% w/w) and (2) mechanical scouring. The green lentils and chickpeas showed distinctive differences in all of the studied properties with pre-treatments. Moisture contents were higher in the scoured green lentil flours, while in the scoured chickpea flours were often lower within moisture conditioning levels. For many of the scoured flours, protein content was lower compared to the unscoured flours within moisture conditioning levels. Scouring was associated with higher L*a*b* color in the green lentil flours; however, for the chickpea flours, L*a*b* were less influenced by scouring. Green lentil middling and straight grade (SG) flours were more refined with scouring. Ash content and water-holding capacity values were not significantly different between the pre-treatment conditions for both pulse types. Differences in flour property results between pre-treatment conditions were significantly different (P < 0.05) in the SG flours. These research findings could serve as a basis for the optimization and design of flour milling operations suitable for dry legumes and thereby improve the application of these high protein pulse flours in processed end-products to satisfy the desire for greater diversity in the food product market.

Similar content being viewed by others

Availability of Data and Material

The authors declare that the data supporting the findings of this study are available within the article. The raw/derived data supporting the findings of this study are available from the corresponding author on request.

References

AACCI. (1999a). Approved methods of analysis. In AACC International Method 44–15.02. Moisture – Air-Oven Methods (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-44-15.02

AACCI. (1999b). Approved methods of analysis. In AACC Approved Method 08–01.01. Ash – Basic Method (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-08-01.01

AACCI. (1999c). Approved methods of analysis. In AACC International Method 46–30.01. Crude Protein – Combustion Method (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-46-30.01

AACCI. (1999d). Approved methods of analysis. In AACC International Method 14–30.01. Agtron Color Test for Flour (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-14-30.01

AACCI. (2017). Approved methods of analysis. In AACC Approved Method 56–37.01. Water-Holding Capacity of Pulse Flours and Protein Materials (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-56-37.01

Anderson, J., & Major, A. (2002). Pulses and lipaemia, short- and long-term effect: Potential in the prevention of cardiovascular disease. British Journal of Nutrition, 88(S3), 263–271. https://doi.org/10.1079/BJN2002716

Asif, M., Rooney, L. W., Ali, R., & Riaz, M. N. (2013). Application and opportunities of pulses in food system: A review. Critical Reviews in Food Science and Nutrition, 53(11), 1168–1179.

Becerra-Tomás, N., Díaz-López, A., Rosique-Esteban, N., Ros, E., Buil-Cosiales, P., Corella, D., Estruch, R., Fitó, M., Serra-Majem, L., Arós, F., Lamuela-Raventós, R., Fiol, M., Santos-Lozano, J., Díez-Espino, J., Portoles, O., & Salas-Salvadó, J. (2017). Legume consumption is inversely associated with type 2 diabetes incidence in adults: A prospective assessment from the PREDIMED study. Clinical Nutrition (Edinburgh, Scotland), 37(3), 906–913. https://doi.org/10.1016/j.clnu.2017.03.015

Bekkering, E. (2014). Pulses in Canada -Canadian Agriculture at a Glance. Statistics Canada, 1–12. https://publications.gc.ca/collections/collection_2014/statcan/96-325-x/CS96-325-2011-7-eng.pdf

Black, R., Singh, U., & Meares, C. (1998). Effect of genotype and pretreatment of field peas (Pisum sativum) on their dehulling and cooking quality. Journal of the Science of Food and Agriculture, 77(2), 251–258.

Brar, N. K., Ramachandran, R. P., Cenkowski, S., & Paliwal, J. (2021). Effect of superheated steam- and hot air-assisted processing on functional and nutritional properties of yellow peas. Food and Bioprocess Technology, 14, 1684–1699. https://doi.org/10.1007/s11947-021-02668-1

Cappelli, A., Oliva, N., & Cini, E. (2020). Stone milling versus roller milling: A systematic review of the effects on wheat flour quality, dough rheology, and bread characteristics. Trends in Food Science & Technology, 97, 147–155. https://doi.org/10.1016/j.tifs.2020.01.008

Chidananda, K. P., Chelladurai, V., Jayas, D. S., Alagusundaram, K., White, N. D. G., & Fields, P. G. (2014). Respiration of pulses stored under different storage conditions. Journal of Stored Products Research. 59: 42-47, https://doi.org/10.1016/j.jspr.2014.04.006

Di-Cairano, M., Condelli, N., Caruso, M. C., Cela, N., Tolve, R., & Galgano, F. (2021). Use of underexploited flours for the reduction of glycaemic index of gluten-free biscuits: Physicochemical and sensory characterization. Food and Bioprocess Technology, 14, 1490–1502. https://doi.org/10.1007/s11947-021-02650-x

Doblado-Maldonado, A. F., Pike, O. A., Sweley, J. C., & Rose, D. J. (2012). Key issues and challenges in whole wheat flour milling and storage. Journal of Cereal Science, 56(2), 119–126. https://doi.org/10.1007/s11947-021-02650-x

Erskine, W., Williams, P., & Nakkoul, H. (1991a). Splitting and dehulling lentil (Lens culinaris): Effects of genotype and location. Journal of the Science of Food and Agriculture, 57(1), 85–92. https://doi.org/10.1002/jsfa.2740570110

Erskine, W., Williams, P., & Nakkoul, H. (1991b). Splitting and dehulling lentil (Lens culinaris): Effects of seed size and different pretreatments. Journal of the Science of Food and Agriculture, 57(1), 77–84. https://doi.org/10.1002/jsfa.2740570109

Fang, Q., Bölöni, I., Haque, E., & Spillman, C. K. (1997). Comparison of energy efficiency between a roller mill and a hammer mill. Applied Engineering in Agriculture, 13(5), 631–635. https://doi.org/10.13031/2013.21636

Fujiwara, N., Hall, C., & Jenkins, A. (2017). Development of low glycemic index (GI) foods by incorporating pulse ingredients into cereal-based products: Use of in vitro screening and in vivo methodologies. Cereal Chemistry, 94(1), 110–116. https://doi.org/10.1094/CCHEM-04-16-0119-FI

Goyal, R. K., Vishwakarma, R. K., & Wanjari, O. D. (2009). Optimization of process parameters and mathematical modelling for dehulling of pigeonpea. International Journal of Food Science & Technology, 44(1), 36–41. https://doi.org/10.1111/j.1365-2621.2007.01630.x

Gularte, M. A., Gómez, M. & Rosell, C. M. (2012). Impact of legume flours on quality and in vitro digestibility of starch and protein from gluten-free cakes. Food and Bioprocess Technology, 5, 3142–3150. https://doi.org/10.1007/s11947-011-0642-3

Izydorczyk, M. S., McMillan, T. L., Kletke, J. B., & Dexter, J. E. (2011). Effects of pearling, grinding conditions, and roller mill flow on the yield and composition of milled products from hull-less barley. Cereal Chemistry, 88(4), 375–384. https://doi.org/10.1094/CCHEM-10-10-0147

Jan, S. & Shieh, G. (2014). Sample size determinations for Welch’s test in one-way heteroscedastic ANOVA. British Journal of Mathematical & Statistical Psychology, 67(1), 72–93. https://doi.org/10.1111/bmsp.12006

Jerish Joyner, J. & Yadav, B. (2015). Optimization of continuous hydrothermal treatment for improving the dehulling of black gram (Vigna mungo L). Journal of Food Science and Technology, 52(12), 7817–7827. https://doi.org/10.1007/s13197-015-1919-8

Kent, N. L. & Evers, A. D. (1994). Kent’s technology of cereals – An introduction for students of food science and agriculture (4th ed.). Oxford, UK: Elsevier Science Ltd.

Kihlberg, I., Johansson, L., Kohler, A., & Risvik, E. (2004). Sensory qualities of whole wheat pan bread – Influence of farming system, milling and baking technique. Journal of Cereal Science, 39(1), 67–84. https://doi.org/10.1016/S0733-5210(03)00067-5

Marinangeli, C., Kassis, A., & Jones, P. (2009). Glycemic responses and sensory characteristics of whole yellow pea flour added to novel functional foods. Journal of Food Science, 74(9), S385–S389. https://doi.org/10.1111/j.1750-3841.2009.01347.x

Nagi, H. P. S. & Bains, G.S. (1983). Effect of scouring and conditioning variables on milling, rheological and baking properties of Indian wheats. Journal of Food Science and Technology, 20(3), 122–124.

Pagani, M. A., Giordano, D., Cardone, G., Pasqualone, A., Casiraghi, M. C., Erba, D., Blandino, M., & Marti, A. (2020). Nutritional features and bread-making performance of wholewheat: Does the milling system matter? Foods, 9(8), 1035–1052. https://doi.org/10.3390/foods9081035

Pelgrom, P., Boom, R., & Schutyser, M. (2015). Method development to increase protein enrichment during dry fractionation of starch-rich legumes. Food and Bioprocess Technology, 8(7), 1495–1502. https://doi.org/10.1007/s11947-015-1513-0

Phirke, P., Bhole, N., & Adhaoo, S. (1995). Shear forces for dehulling, splitting and breaking raw and pretreated pigeonpeas. International Journal of Food Science & Technology, 30(4), 485–491. https://doi.org/10.1111/j.1365-2621.1995.tb01395.x

Posner, E. S., & Hibbs, A. N. (2005). Wheat flour milling (2nd ed.). St. Paul, Minnesota, U.S.A.: American Association of Cereal Chemists, Inc.

Prabhasankar, P., & Rao, P. H. (2001). Effect of different milling methods on chemical composition of whole wheat flour. European Food Research & Technology, 213(6), 465–469. https://doi.org/10.1007/s002170100407

Reichert, R., Oomah, B., & Youngs, C. (1984). Factors affecting the efficiency of abrasive-type dehulling of grain legumes investigated with a new intermediate-sized, batch dehuller. Journal of Food Science, 49(1), 267–272. https://doi.org/10.1111/j.1365-2621.1984.tb13723.x

Ringuette, C., Finley, J., Prinyawiwatkul, W., & King, J. (2018). Development of reduced glycemic load/high fiber ravioli using bean flour. Journal of Culinary Science & Technology, 16(4), 336–356. https://doi.org/10.1080/15428052.2017.1391147

Rizzello, C., Calasso, M., Campanella, D., De Angelis, M., & Gobbetti, M. (2014). Use of sourdough fermentation and mixture of wheat, chickpea, lentil and bean flours for enhancing the nutritional, texture and sensory characteristics of white bread. International Journal of Food Microbiology, 180, 78–87. https://doi.org/10.1016/j.ijfoodmicro.2014.04.005

Sakhare, S. D., Inamdar, A. A., Gaikwad, S. B., Indrani, D., & Rao, G. V. (2014). Roller milling fractionation of green gram (Vigna radiata): Optimization of milling conditions and chemical characterization of millstreams. Journal of Food Science and Technology, 51(12), 3854–3861. https://doi.org/10.1007/s13197-012-0903-9

Sakhare, S. D., Inamdar, A. A., Indrani, D., Madhu Kiran, M. H., & Venkateswara Rao, G. (2015). Physicochemical and microstructure analysis of flour mill streams and milled products. Journal of Food Science and Technology, 52(1), 407–414. https://doi.org/10.1007/s13197-013-1029-4

Sarkar, A., & Subramaniam, M. (2016). Processing of pulses for nutrition, product diversification and profitability in the milling industry. International Miller, 2Q, 34–43.

Scanlon, M. G., Thakur, S., Tyler, R. T., Milani, A., Der, T., & Paliwal, J. (2018). The critical role of milling in pulse ingredient functionality. Cereal Foods World, 63(5), 201–206. https://doi.org/10.1094/CFW-63-5-0201

Siddiq, M., & Uebersax, M. A. (2013). Dry beans and pulses production and consumption – An overview. In M. Siddiq, & M. A. Uebersax (Eds.), Dry Beans and Pulses Production, Processing and Nutrition (1st ed., pp. 1–22). Oxford: John Wiley & Sons, Inc. https://doi.org/10.1002/9781118448298.ch1

Sunil, C., Chidanand, D., Manoj, D., Choudhary, P., & Rawson, A. (2018). Effect of ultrasound treatment on dehulling efficiency of blackgram. Journal of Food Science and Technology, 55(7), 2504–2513. https://doi.org/10.1007/s13197-018-3168-0

Venn, B., Perry, T., Green, T., Skeaff, C., Aitken, W., Moore, N., Mann, J., Wallace, A., Monro, J., Bradshaw, A., Brown, R., Skidmore, P., Doel, K., O’Brien, K., Frampton, C., & Williams, S. (2010). The effect of increasing consumption of pulses and wholegrains in obese people: A randomized controlled trial. Journal of the American College of Nutrition, 29(4), 365–372. https://doi.org/10.1080/07315724.2010.10719853

Vishwakarma, R. K., Shivhare, U. S., Gupta, R. K., Yadav, D. N., Jaiswal, A., & Prasad, P. (2018). Status of pulse milling processes and technologies: A review. Critical Reviews in Food Science and Nutrition, 58(10), 1615–1628. https://doi.org/10.1080/10408398.2016.1274956

Wang, N. (2008). Effect of variety and crude protein content on dehulling quality and on the resulting chemical composition of red lentil (Lens culinaris). Journal of the Science of Food and Agriculture, 88(5), 885–890. https://doi.org/10.1002/jsfa.3165

Willard, J. T., & Swanson, C.O. (1911). Milling tests of wheat and baking tests of flour. Manhattan, Kansas, U.S.A.: Kansas State Agricultural College, Experiment Station, Bulletin 177. http://www.ksre.k-state.edu/historicpublications/pubs/SB177.PDF. Accessed 22 October 2021.

Winterová, R., Holasová, M., & Fiedlerová, V. (2016). Effect of spelt pearling on the contents of total dietary fibre, wet gluten, protein and starch fractions. Czech Journal of Food Sciences, 34(1), 61–67. https://doi.org/10.17221/453/2015-CJFS

Wood, J. A., & Malcolmson, L. (2011). Pulse milling technologies. In B. K. Tiwari, A. Gowen, & B. McKenna (Eds.), Pulse foods: Processing, quality and nutraceutical applications (1st ed., pp. 193–221). London: Academic Press. https://doi.org/10.1016/B978-0-12-382018-1.00008-3

Zhao, B., Wang, L., Shang, J., Liu, L., Tong, L., Zhou, X., Wang, S., Zhang, Y., & Zhou, S. (2020). Application of pearling in modified roller milling of hull‐less barley and effect on noodles quality. Journal of Food Processing and Preservation, 44(11). https://doi.org/10.1111/jfpp.14838

Acknowledgements

We thank Canada Foundation for Innovation for infrastructural support and Canadian International Grains Institute for milling of samples. Sincere thanks to Ms. Lindsey Boyd (Technologist, Pulse Science Cluster, Cereals Canada, Winnipeg, Canada), Dr. Ning Wang (Research Scientist, Grain Research Laboratory, Canadian Grain Commission, Winnipeg, Canada), Mr. Ashok Sarkar (Senior Advisor, Technology, Cereals Canada, Winnipeg, Canada), and Dr. Mohammad Nadimi (University of Manitoba, Winnipeg, Canada) for their input.

Funding

The authors acknowledge the Pulse Cluster of the Canadian Agricultural Partnership’s AgriScience Program and Natural Sciences and Engineering Research Council of Canada’s Discovery Grant program for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choo, K., Ramachandran, R.P., Sopiwnyk, E. et al. Effects of Seed Moisture Conditioning and Mechanical Scouring Pre-Treatments on Roller-Milled Green Lentil (Lens culinaris) and Chickpea (Cicer arietinum) Flours. Food Bioprocess Technol 15, 1311–1326 (2022). https://doi.org/10.1007/s11947-022-02816-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02816-1