Abstract

This study will provide an overview and a description of the most promising alternatives to conventional thermal treatments for juice stabilization, as well as a review of the literature data on fruit and vegetable juice processing in terms of three key parameters in juice production, which are microbial reduction, enzyme inactivation, and nutrient-compound retention. The alternatives taken into consideration in this work can be divided, according to the action mechanism upon which these are based, in non-conventional thermal treatments, among which microwave heating (MWH) and ohmic heating (OH), and non-thermal treatments, among which electrical treatments, i.e., pulsed electric fields (PEF), high-pressure processing (HPP), radiation treatments such as ultraviolet light (UVL) and high-intensity pulsed light (PL), and sonication (HIUS) treatment, and inert-gas treatments, i.e., the pressure change technology (PCT) and supercritical carbon dioxide (SC-CO2) treatments. For each technology, a list of the main critical process parameters (CPP), advantages (PROS), and disadvantages (CONS) will be provided. In addition, for the non-thermal technologies, a summary of the most relevant published result of their application on fruit and vegetable juices will be presented. On top of that, a comparison of typical specific working energy costs for the main effective and considered technologies will be reported in terms of KJ per kilograms of processed product.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fruit and vegetable juices, beverages, juice blends, smoothies, and purees are an increasingly popular way of consuming fruit and fresh-like vegetables and may contribute to a healthy diet and healthy life. Over the last few years, the consumption of fruit and vegetable juices has been rapidly increasing, making the juice and beverage industry among the largest agro-based industries worldwide (Walkling-Ribeiro et al., 2010).

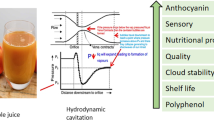

Vegetable and fruit juices are traditionally preserved by thermal processing. Unfortunately, they might have some detrimental effects on the nutritional quality, impacting negatively on the fresh-like characteristics. Therefore, recent consumer demand for safe and minimally processed foods with high-quality attributes have encouraged food industry and scientific researchers to design alternative technologies to produce food with a minimum of changes induced by the technologies themselves (Jiménez-Sánchez et al., 2017a).

For this reason, recently there has been a growing interest in the design of non-conventional and novel non-thermal processing systems that minimally modify sensory, nutritional, and functional properties of fruit and vegetable juices and beverages. The non-conventional and non-thermal technologies that will be presented in this paper could meet industry and consumer expectations. Anyway, although non-conventional treatment seems less detrimental than the conventional thermal ones, the effects are strongly dependent on the food matrix (Alves Filho et al., 2016). Therefore, the main motivation for food processors is to select the most appropriate thermal or non-thermal technology along with validated processing conditions to retain nutritive constituents, color, and flavor attributes (Koutchma et al., 2016).

In the last few years, many studies and research about comparison among different technologies for fruit and vegetable juice treatment have been carried out (Bevilacqua et al., 2018; Jiménez-Sánchez et al., 2017a, b; Qazalbash et al., 2018; Timmermans et al., 2011; Van Impe et al., 2018; Vervoort et al., 2011), but to the best of our knowledge no report gives a comprehensive overview of the advantages, disadvantages, and technological constraints for their application, or provide a comparison of their specific energy consumption with the conventional thermal treatment.

Based on the above premises, as an input to processor choice, this paper will provide an overview of the most promising non-conventional technologies, specifying their mechanisms of action and critical process parameters, reporting the results of their application, and lastly, comparing their specific working energy costs.

Non-conventional Technologies

Thermal Technologies

Microwave heating (MWH) and ohmic heating (OH) are processes based on temperature increasing into the product to which they are applied, but not related to conventional heat transmission methods (conduction and convection). Therefore since their effect on microbial reduction, enzymatic deactivation, and nutrient deterioration is still related to heat, they can be classified as non-conventional thermal technologies.

Microwave Heating

Microwave heating is a sub-category of electrical treatments, where electromagnetic waves are emitted by a small-dimension magnetron and guided through space to the target. Microwaves are electromagnetic waves whose frequency varies from 300 MHz to 300 GHz. The industrial microwave systems typically operate at frequencies from 915 MHz to 2.45 GHz (Datta & Davidson, 2000).

MWH is caused by the ability of the materials to absorb microwave energy and convert it into heat. Microwave heating of food materials mainly occurs due to dipolar and ionic mechanisms. The presence of moisture or water causes dielectric heating due to the dipolar nature of water. There are many factors affecting microwave heating and its heat distribution, but the most important of them are the dielectric properties and penetration depth (Chandrasekaran et al., 2013).

MWH is a promising way for juice stabilization because of some advantages, like the reduced processing time, a good process control, and space savings (Salazar-González et al., 2014). Destruction of microbes or enzymes by microwave or radio frequency waves at sublethal temperatures was explained by one or more of the following theories: selective heating, electroporation, cell membrane rupture, and magnetic field coupling.

The selective heating theory suggests that the microorganisms are selectively heated due to microwaves and reach a temperature higher than that of the surrounding fluid. This causes the microorganisms to be destroyed more quickly. According to the electroporation theory, the electrical potential across the cell membrane causes pores, which results in the leakage of cellular materials. In the cell membrane rupture theory, the cell membrane is ruptured due to the voltage applied across the cell membrane. According to the magnetic field coupling theory, the internal components of the cell are disrupted due to the coupling of electromagnetic energy with critical molecules such as protein or DNA (Kozempel et al., 1998). Although various theories suggest the non-thermal effect of microwaves, it was further observed that in the absence of other stresses such as pH or heat, microwave energy did not inactivate microorganisms (Chandrasekaran et al., 2013).

MWH treatments are nowadays applied by some food industries and were found to save some costs and time compared to indirect heating methods. Also, food quality is maximized and better retained using electromagnetic energy rather than conventional heating. Microwave heating processes used on fruit and vegetable juices can achieve high processing temperatures in shorter times; therefore, more nutritional and sensory properties are conserved.

Ohmic Heating

Ohmic heating (OH) applied to food products involves the passage of high-frequency alternating electric current through them, generating internal heat as a result of electrical resistance — Joule effect — of the food matrix (Valero et al., 2010).

As outlined in Fig. 1, in the typical industrial design for liquid food OH treatment involves the application of a high electrical potential (typically around 5000 V) between the two flanges at the extremities of each module, using the food product flowing through as a resistor. The high-frequency electrical current (typically between 20 and 30 kHz) therefore passes through the food, increasing its temperature fast and uniformly thanks to the Joule effect, thus bypassing conventional heat transfer mechanisms such as conduction and convection.

The heating rate is directly proportional to the square of the electric field strength, and the electrical conductivity of the product (Jiménez-Sánchez et al., 2017a).

For this reason, the efficiency of the application of OH for the stabilization of liquid foods strongly depends on the conductivity of the product to be treated. Typical conductivity value of fruit and vegetable juices is between 0.2 and 1 S/m at 20 °C with lower value for raw water and honey sugar and higher values for meat products and seafood (Zhang, 2007).

The ohmic heating technology has many benefits: for example, compared to the conventional heating, it reduces the problems of surface fouling, or over heating of the product, it has low maintenance costs and high energy conversion efficiencies (Pereira & Vincente, 2010), and retain higher nutritional value of food product (Debbarma et al., 2021), but the different electrode materials during OH at different electrical frequencies have an influence on protein structural aspects (Ferreira et al., 2021).

OH is very effective in fruit and vegetable juices that contain water and ionic salts in abundance (Miller & Silva, 2012). In these kinds of products OH provides uniform and rapid heating, resulting very efficacious for microbial reduction and enzyme inactivation, with a beneficial effect on the nutritional and organoleptic properties of processed products (Mercali et al., 2015). Additionally, compared to conventional thermal technologies, OH offers better energy efficiency, lower capital cost, and shorter treatment time. In addition, it results to be an environmentally friendly process, since around 97% of electrical energy provided is converted into heat (Lee et al., 2015). Figure 2 provides a typical example of liquid food product heating curves on a temperature over time chart, showing the faster temperature rising with OH in comparison with conventional indirect heating technologies.

Non-thermal Technologies

The technologies that will be described in this section are defined as non-thermal because their effect of microbial reduction is not due to the increase of temperature, in contrast to the technologies seen so far, but is a result of different action mechanisms, specific for each technology.

Pulsed Electric Fields

Pulsed electric field (PEF) is one of the most extensively studied non-thermal technologies that had been applied to fruit and vegetable juices for microorganism inactivation as well as for maintaining organoleptic and nutritional qualities similar to those of fresh juice.

This treatment involves the application of high-intensity electric field (typically between 10 and 40 kV/cm), in form of very short pulses (usually 5–30 μs), to a product placed between two electrodes. The application of PEF pulses induces microscopic pores — called electropores — in the microbiological membranes, resulting in an increase in their permeability. The plasma membranes of cells become hence permeable to small molecules, ions, and water, which will be able to pass from one side of the membrane to the other. This phenomenon is called electroporation and induces swelling and the rupture of the cell membrane leading to cell death (Jiménez-Sánchez et al., 2017a).

Although a temperature might rise due to the electric current flowing through the liquid food (as it happens during ohmic heating), PEF is intended to be a non-thermal technique (Jiménez-Sánchez et al., 2017a).

In addition, even if the application of PEF at relatively lower temperatures to inactivate pathogens and food spoilage bacteria, as well as enzymes, has already been described in the literature, a better understanding and accurate prediction of inactivation levels are necessary to achieve enzymatically stable products without overprocessing (Bevilacqua et al., 2018).

High-Pressure Processing

High-pressure processing (HPP) refers to the application of hydrostatic pressure in the range from 100 to over 900 MPa on pre-packaged food. During this process, the pressurization is applied isostatically, i.e., equally in all for the duration of the treatment and then released (Jiménez-Sánchez et al., 2017a).

High pressure causes unfolding of proteins or enzymes, as well as considerable damage to the genetic material of microorganisms, due to phase transition fluidity change of the cell membrane, an intracellular pH change, and breakdown of ribosomes, ultimately resulting in injury and death of vegetative microorganisms (Qazalbash et al., 2018). On the other hand, this technology exerts limited effects on small molecules such as volatile compounds, pigments, vitamins, and antioxidant compounds (Stefanini et al., 2021), owing to its limited impacts on the covalent bonds and its low processing temperature (Chen et al., 2015). This led to the commercial adoption of this treatment for increasing the shelf life of juices and for manufacturing of high-quality products.

Figure 3 shows a schematic example of HPP technology application: HPP is typically applied as a batch process in which pre-packed products are loaded into the pressure vessel. As soon as they are loaded and closed, the vessel is filled with pressure-transmitting fluid, by using a pressure-generating mean. A pressure medium, water in most current HPP equipment (Rastogi, 2013), is pumped isostatically from its tank into the pressure vessel and once the desired pressure is reached, the pump is stopped by closing the inlet valves (Elamin et al., 2015). The desired pressure can be maintained with no more energy needed to hold it (Huang et al., 2014). After holding the product for the required time, the pressure is released from the vessel by freeing out the pressure-transmitting fluid to return to its initial tank reservoir (Farkas & Hoover, 2000).

It is also important to notice that although HHP is intended to be a cold (totally non-thermal) technology, an inherent mild increase in pressurized water temperature does occur. The temperature increasing during compression is reported to be approximately 3 °C every 100 MPa (Timmermans et al., 2011).

Pressure Change Technology

Pressure change technology (PCT) is an emerging process which has been recently proposed as an innovative approach for the non-thermal inactivation of microorganisms and stabilization of liquid foods (Aschoff et al., 2016).

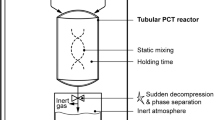

A schematic representation of PCT process application is provided in Fig. 4. When pressure change technology (PCT) is applied, the liquid product is pressurized with a high-pressure pump at a maximum pressure of 50 MPa and subsequently mixed with an inert gas (such as nitrogen, helium, or argon) at a slightly higher pressure (approximately 1 MPa) using an inline static mixer. During the subsequent holding time, the inert gas dissolves and diffuses in the liquid medium in high amounts, penetrating into intracellular microbial liquids until reaching saturation. After the retention time, the pressurized product saturated with gas is quickly released to atmospheric pressure by a relief valve.

This flash decompression causes a sudden outgassing of the inert gas, which damages all the microbial cell structures into which it has penetrated but minimizes the impact on enzyme activity and nutritional compounds. Thus, in contrast to static technologies such as high-pressure processing, the lethal effect of PCT is achieved at the dynamic decompression step instead of during the retention time (Aschoff et al., 2016). Therefore, the stabilization mechanism of PCT can be called dynamic decompression.

Ultraviolet Light Radiation

Among the non-thermal technologies developed in the last few decades, ultraviolet light (UVL) processing is one of the most promising because it is easy to use, lethal to most microorganisms, and it is a cold process that can be effective at low cost in comparison with other preservation methods (Gayán et al., 2012). A schematic example of industrial UVL technology application is provided in Fig. 5.

The wavelength range for UVL for food processing varies from 100 to 400 nm and is categorized as UV-A (320–400 nm), UV-B (280–320), and UV-C (200–280 nm). UV-C radiation, especially the wavelength of 254 nm, is considered the germicidal region in which the main bactericidal effect occurs (Gayán et al., 2012).

The inactivation of microorganisms starts with the microorganism’s DNA absorbing UV radiation, and then cross-linked pyrimidine nucleoside bases are formed causing a mutation in the DNA, mainly thymine dimmers. The structural damage caused by the formation of these dimmers inhibits the formation of new DNA, resulting in the inactivation of the affected microorganism. This reaction has been called the photochemical effect (Gómez-López et al., 2012).

Pulsed Light Radiation

Recently, pulsed light (PL) has been intensely investigated as an alternative to thermal treatments for killing pathogenic and spoilage microorganisms (Maftei et al., 2014). It is based on application of very short intense flashes of light. The equipment used consists of a high-energy electrical energy capacitor that discharges pulses of electrical energy to flash lamps which produce flashes of broad-spectrum light. The spectrum of emitted light is in the range of 200–1100 nm. The emitted flashes are very intense but have an extremely short duration (0.2–0.4 ms).

In addition to the photochemical effect previously mentioned for the UVL technology, exposure to PL also causes a membrane disruption as a result of a momentous overheating. This phenomenon is attributed to a difference in UV light absorption between the microorganism and its surrounding environment, called photothermal effect. Besides, structural damage in microbial cells like cytoplasmic membrane shrinkage was also reported, called photophysical effect (Ferrario et al., 2014).

Also in this case, the outline for PL treatment application has been provided in Fig. 6.

Supercritical Carbon Dioxide

Among the non-thermal process for liquid foods such as fresh juices, there is also a method called dense phase carbon dioxide (DPCD) or supercritical carbon dioxide (SC-CO2) that is able to inactivate microorganisms and enzymes using CO2 in the supercritical state (Deng et al., 2020). Foods are subject to sub-critical or supercritical (i.e., pressurized) CO2 at low temperature (20–50 °C) under moderate pressure (below 50 MPa) for 5–30 min (Ferrentino & Spilimbergo, 2011). CO2 has many advantages: it is inert to oxidation reactions, non-flammable, non-corrosive, non-toxic, safe solvent, and has low critical temperature, which allows the development of non-thermal process, therefore minimizing the influence on sensorial and nutritional characteristics of foods (Silva et al., 2020).

The equipment for SC-CO2 processing of liquid foods is specific to each application and the process may be operated in batch, semicontinuous, or pseudo-continuous and continuous operating mode (Perrut, 2012).

This technology has been investigated over the past 50 years: its effects on various microorganisms including pathogens, spoilage bacteria, yeasts and molds, and different enzymes have been demonstrated (Fleury et al., 2018). Several studies have been performed on the efficiency of SC-CO2 processing in the preservation of juices, such as mango (Tang et al., 2021), tomato (Zhao et al., 2019), orange (Niu et al., 2019), apple (Gasperi et al., 2009), guava (Plaza et al., 2015), and melon (Pei et al., 2018). Few studies evaluated the shelf life of natural juices processed by SC-CO2 technology, regarding microbial quality and other parameters (Torabian et al., 2018; Zou et al., 2016). Moreover, the literature regarding the effects of SC-CO2 technology on the sensory properties as well as the acceptance of the non-thermally processed juices by the consumers is still scarce (Silva et al., 2020). This type of process, although known to the applied research sector, still finds little attention in the food industry today.

High-Intensity Ultrasound

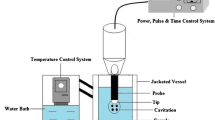

High-intensity ultrasound (HIUS) refers to ultrasound operating at frequency higher than 20 kHz: this technology gained success in the field of food disinfection (Afari et al., 2016). To get the ultrasound, an electric current alternating is applied to a piezoelectric material fixed to the wall of a container. A sonicator consists of an electricity generator, a converter to transform electrical energy into mechanical energy, and probes that amplify the produced vibration.

The mechanism of operation of the sonication is based on the phenomenon of cavitation, with the formation of small bubbles in the liquid medium that quickly alternates compression and expansion and cause violent collapse. Shock waves with high energy densities can radiate from collapsing bubbles that are strong enough to shear and break cell walls and membrane structures, as well as depolymerize large molecules (Deng et al., 2020). Therefore, this process is able to guarantee a bactericide effect (Gómez et al., 2011). Moreover, hydroxyl radicals can be formed due to the rise of temperature at a localized position inside a collapsing bubble: they can react with the DNA chain and break the double-strand microbial DNA (Bilek & Turantaş, 2013).

However, even if HIUS is generally considered safe, non-toxic, and environmentally friendly (Deng et al., 2020), information on its commercial application is scarce and more efforts are needed to develop large-scale inexpensive equipment for their application in the food industry.

Fruit and Vegetable Juice Stabilization Effectiveness

Although the effectiveness of heat treatments is well known and does not change significantly depending on the technology used to apply the heat (conventional or non-conventional), the results of non-thermal technologies are often uncertain and may differ depending on the variation in process parameters.

In Table 1, what we consider to be the most representative data found in the scientific literature regarding the effectiveness of the main non-thermal technologies has been summarized, in terms of the three key aspects of microbial reduction, enzymatic inactivation, and nutrient-compound retention for each standpoint. The results obtained and the process conditions applied have been reported.

Technological Constraints

Following the description and the effects of the various stabilization technologies reported in the previous sections of this work, it is possible to summarize a list of the principal critical process parameters (CPP), advantages (PROS), and disadvantages (CONS) associated with each of these processes.

In Table 2, an overview of the above aspects is provided for each technology, reporting also the data source.

Working Energy Cost Comparison

Starting from the technical features, the process flow diagrams, and the operating mechanism of the technologies taken into account in this paper, the energy consumption per mass unit of treated product has been estimated in order to perform a comparison of the specific energy cost required by each of them. For this comparison, also an estimation for the conventional indirect thermal treatment (CITT) has been considered.

The estimation of the specific working energy consumption for each technology has been carried out starting from the method reported by Rodriguez-Gonzalez et al. (2015), with the following further assumptions:

-

The components of working costs considered are those for product stabilization treatment (i.e., energy for heating and pumping), other service fluid pumping, heat dissipation (i.e., for equipment cooling), and for product cooling.

-

The evaluation of energy consumption per unit mass of juice processed has been carried on a system boundary going from inlet untreated product to outlet stabilized product, considering both with the same temperature value equal to 20 °C.

-

In the cases of thermal treatments, the use of a process temperature not exceeding 68 °C were assumed.

This latter condition was assumed in order to make the comparison between different technologies as fair as possible. In fact, thermal processes reaching temperatures higher than the herein imposed are able to reach levels of product stability, i.e., shelf life, often inaccessible with non-thermal technologies, which would nevertheless penalize them from an energy point of view.

Approximately 5-log reduction of Escherichia coli in apple-derived products was taken into consideration as target for all the stabilization technologies under consideration. The treatment conditions to achieve such E. coli inactivation levels and, therefore, utilized for specific energy cost estimation for the different technologies are the following:

-

CITT/OH/MWH:A treatment at 68 °C for 15 s has been considered, since more than 5-log reduction of non-adapted and acid-adapted E. coli O157:H7 was obtained at 68.1 °C for 14 s in apple cider at pH 4.1 and 11 °Brix (Mak et al., 2001).

-

HPP:A treatment at 600 MPa for 2 min has been considered, since for high-pressure treatment, literature reports 1–5 min at 350–600 MPa to inactivate E. coli in apple juice (Daher et al., 2017). Also, 3 min for pressure fluid to come up to the desired pressure was estimated.

-

PEF:A treatment with monopolar pulses of 2-μs duration at electric field strength of 23 kV/cm has been considered. In addition, it was estimated a preheating of the product to 44 °C and a post PEF treatment temperature of 56 °C at a repetition rate of 90 Hz and a flow rate of 130 L/h. Also energy for product preheating and cooling have been taken into account.

-

UVL/PL:For both technologies, a treatment module made of 24 lamps with 65-W output power each has been considered. In this study, pilot modules with a flow rate of approximately 20 L/min were chosen. Such parameters are able to achieve the desired bacterial inactivation in clear apple cider according to industries.

-

PCT:Since no data on E. coli inactivation in apple juice have been found in scientific literature, the energy cost estimation in this case has been done starting from the process parameters described by Aschoff et al. (2016), i.e., product pressure of 50 MPa, Tmax < 40 °C, and 1.3-min holding time.

As far as the SC-CO2 and HIUS treatments are concerned, the literature is scarce and the data available for microbial inactivation are very low in comparison to the other technologies: for example, only 1.3 log reduction of E. coli was reached in orange juice treated with HIUS (42 kHz, 60 min) (Kernou et al., 2021). Therefore, since the established target of 5-log reduction of E. coli in apple-derived products is not achieved, these two treatments cannot be considered in this evaluation.

For thermal treatments, i.e., CITT, OH, and MW, the most commonly used equation is the one related to heat content which considers a physical property (specific heat capacity or Cp) to estimate the energy required to change the temperature of a material. This equation is utilized in food materials as well as equipment materials and is an indicator of heat transfer by conduction (Singh & Heldman, 2001; Toledo, 2007):

where Eh is the specific energy for heating, Cp is the specific heat capacity, m is the mass to be heated, ∆T is the temperature differential, and η is the system efficiency.

This equation can be used for a valid prediction of heating costs also for non-conventional thermal technologies, i.e., OH and MWH. In this study, the efficiency values of 90%, 97%, and 85%, respectively, for CITT, OH, and MW have been considered. The same equation has been referred to also for cooling energy cost estimation.

In addition, for the non-conventional thermal technologies, in which the product is heated without direct contact with hot surfaces, the electric energy not converted in food heating need to be dissipated. For this reason, an additional energy cost for electric equipment’s cooling system (Ed) has been considered:

The basic equation used for estimating the energy required to pump fluids through pipes is the following:

where Ep is the specific energy for pumping, V̇ is the volumetric flow rate, and η is the pump efficiency.

The total amount of working energy consumption for thermal treatments has therefore been calculated by summing the three contributes above described:

In the case of 65% of heat recovery, the energy savings are considerable in terms of both product warming and cooling, as well as heat dissipation.

The internal energy requirement for HPP can be estimated basing on process control metrics using the pressure head component of pump power calculation equations (Rodriguez-Gonzalez et al., 2015):

where Es is the specific energy, P is the pressure, and ρ is the density. The same equation has been utilized also for PCT running cost estimations, being the fluids (product and inert gas) pumping the only energy requiring contribute.

A measure of the specific energy input for PEF process can be estimated using the following equation (in a thermodynamic system is enthalpy, and its change as a function of temperature is also applicable to PEF (Heinz et al., 2003):

where Es is the specific energy for heating and E, k(T), f, and ṁ denotes the electric field strength, the media conductivity, the repetition rate, and the mass flow rate, respectively (Toepfl et al., 2007).

For both UVL and PL processes, lastly, the total applied UV energy for treatment of a liter of liquid product in a continuous-flow unit can be calculated using the following equation, as UV output power of the n number of the UV sources divided by volumetric flow rate (V̇) of the treated fluid (Keyser et al., 2008) in (J/L).

where Es is the specific energy for heating, PUV is the output power, LN is the number of lamps, and V̇ is the is the volumetric flow rate. The results have than been divided by the estimated product density ρ in order to evaluate the specific energy per kg.

Any eventual data missing or to be integrated have been obtained from the scientific papers by Gómez-López et al. (2012), Cacace et al. (2020), and Vollmer et al. (2020). In addition, information from the literature has been cross-checked with experts from leading companies in the field of fruit and vegetable juice processing technology, such as CFT (Catelli Food Technology) and Elea Vertriebs- und Vermarktungsgesellschaft mbH.

All the results of the estimates have been expressed in kJ over kg of treated product. Both cases of no heat recovery and 65% of heat recovery have been reported in Tables 3 and 4, as well as in the subsequent Figs. 7 and 8. The specific working energy costs resulted very high for the microwave heating, followed by the conventional indirect thermal treatment, the ohmic heating, the high-pressure processing, and pulsed electric fields. On the other hand, it resulted very low for ultraviolet light radiation, pulsed light radiation, and pressure change technology. However, considering the 65% of heat recovery, the estimated results change: HPP is characterized by the highest specific working energy costs, followed by MHW, OH, CITT, and PEF, while UVL, PL, and PCT continue to result as the lowest ones.

In the second graph, the specific energy consumption estimated for the thermal technologies and those technologies that involve a product pre-heating such as PEF are much lower than in the second, since the energy recovery system allows energy saving of around 36% on the total process. This comparison was made by fully including the energy for product cooling, but cheaper alternatives (in terms of energy) could also be considered such as well cooling-towers to be recovered somewhere else in the process.

Furthermore, for OH and MWH technologies, the heat recovery system allows a lower overheating of the electrodes and magnetrons since the thermal increase that must be provided to the product would be lower. This therefore reduces heat dissipation and thus the energy costs for cooling the equipment.

Even the PEF technology, although not thermal, involves, as previously mentioned, a temperature increases of the product and therefore gains benefits in terms of energy consumptions from the heat recovery system.

Completely non-thermal processes such as HPP, UVL, and PCT, as can be seen, do not involve any energy costs for product and equipment cooling, so their specific energy consumption is still constant in both graphs. In contrast, for the PL technology, a minimal energy cost for the lamps cooling should always be taken into account. The high-energy requirements of HPP technology are due to the achievement of the high pressures for product treatment; therefore, no benefits in terms of energy consumptions could come from a heat recovery system.

Conclusions

This work provides an overview of some of the existing alternatives to conventional thermal treatments, currently utilized to achieve the safety and improved quality of fruit and vegetable juices. Thermal treatments are still the most commonly used methods and the only ones capable of effectively inactivating spores and enzymes for the production of low-acid shelf stable products. Non-conventional thermal treatments such as OH and MWH are gaining great success among the producers, since they allow to reach very quickly the high temperatures for stabilization processes, leading in many cases to a better retention of the nutritional and sensory properties of products.

Non-thermal approaches seem to offer the most effective alternative in terms of nutrients and fresh-like characteristics preservation as well as working energy costs saving, but they also have many limits. In fact, targeting pathogen microorganism only, they are often able to obtain exclusively the sanitary treatment, with variable effects on spoilage microorganisms and enzymes, leading to final products requiring refrigerated storage. In addition, some non-thermal approaches, such as PEF, HPP, and UVL, are currently used for industrial applications, while others, like PCT, PL, HIUS, and SC-CO2, are still at pilot-scale level and their scale-up represents a challenge.

Therefore, it is fundamental for each producer aiming to choose the best technology for achieving or improving the desired final product or production process, to take into consideration, compare, and possibly to further investigate all the various critical parameters and technical aspects presented in this overview.

Change history

20 July 2022

Missing Open Access funding information has been added in the Funding Note.

References

Alves Filho, E. G., Almeida, F. D., Cavalcante, R. S., de Brito, E. S., Cullen, P. J., Frias, J. M., Bourke, P., Fernandes, F. A., & Rodrigues, S. (2016). 1H NMR spectroscopy and chemometrics evaluation of non-thermal processing of orange juice. Food Chemistry, 204, 102–107. https://doi.org/10.1016/j.foodchem.2016.02.121

Afari, G. K., Hung, Y. C., King, C. H., & Hu, A. (2016). Reduction of Escherichia coli O157: H7 and salmonella typhimurium DT 104 on fresh produce using an automated washer with near neutral electrolyzed (NEO) water and ultrasound. Food Control, 63, 246–254. https://doi.org/10.1016/j.foodcont.2015.11.038

Akgün, M. P., & Ünlütürk, S. (2017). Effects of ultraviolet light emitting diodes (LEDs) on microbial and enzyme inactivation of apple juice. International Journal of Food Microbiology, 260, 65–74. https://doi.org/10.1016/j.ijfoodmicro.2017.08.007

Aschoff, J. K., Knoblauch, K., Hüttner, C., et al. (2016). Non-thermal pasteurization of orange (Citrus sinensis (L.) Osbeck) juices using continuous pressure change technology (PCT): A proof-of-concept. Food and Bioprocess Technology, 9, 1681–1691. https://doi.org/10.1007/s11947-016-1754-6

Bevilacqua, A., Petruzzi, L., Perricone, M., Speranza, B., Campaniello, D., Sinigaglia, M., & Corbo, M. R. (2018). Nonthermal technologies for fruit and vegetable juices and beverages: Overview and advances. Comprehensive Reviews in Food Science and Food Safety, 17, 2–62. https://doi.org/10.1111/1541-4337.12299

Bilek, S. E., & Turantaş, F. (2013). Decontamination efficiency of high power ultrasound in the fruit and vegetable industry, a review. International Journal of Food Microbiology, 166(1), 155–162. https://doi.org/10.1016/j.ijfoodmicro.2013.06.028

Bönsch, K., Wecks, M., Ondruschka, J., & Staudt, R. (2007). The effect of a new pressure change technology (PCT) on microorganisms: An innovate concept for food safety. Chemical Engineering and Technology, 30, 755–757. https://doi.org/10.1002/ceat.200600402

Cacace, F., Bottani, E., Rizzi, A., & Vignali, G. (2020). Evaluation of the economic and environmental sustainability of high pressure processing of foods. Innovative Food Science & Emerging Technologies, 60, 102281. https://doi.org/10.1016/j.ifset.2019.102281

Chandrasekaran, S., Ramanathan, S., & Basak, T. (2013). Microwave food processing—A review. Food Research International (Ottawa, Ont.), 52(1), 243–261. https://doi.org/10.1016/j.foodres.2013.02.033

Chen, D., Wu, J., & Zhao, J., et al. (2015). Comparing the effects of high hydrostatic pressure and high temperature short time on papaya beverage. Innovative Food Science & Emerging Technologies, 32, 16–28. https://doi.org/10.1016/j.ifset.2015.09.018

Daher, D., Le Gourrierec, S., & Pérez-Lamela, C. (2017). Effect of high pressure processing on the microbial inactivation in fruit preparations and other vegetable based beverages. Agriculture, 7(9), 72. https://doi.org/10.3390/agriculture7090072

Datta, A. K., & Davidson, P. M. (2000). Microwave and radio frequency processing. Journal of Food Science, 65, 32–41. https://doi.org/10.1111/j.1745-4565.2000.tb00616.x

Debbarma, T., Thangalakshmi, S., Tadakod, M., Singh, R., & Singh, A. (2021). Comparative analysis of ohmic and conventional heat-treated carrot juice. Journal of Food Processing and Preservation, 45(9). https://doi.org/10.1111/jfpp.15687

Deng, L., Mujumdar, A. S., Pan, Z., Vidyarthi, S. K., Xu, J., Zielinska, M., & Xiao, H. (2020). Emerging chemical and physical disinfection technologies of fruits and vegetables: A comprehensive review. Critical Reviews in Food Science and Nutrition, 60(15), 2481–2508. https://doi.org/10.1080/10408398.2019.1649633

Elamin, W., Endan, J., & Yosuf, Y., Shamsudin, R., & Ahmedov, A. (2015). High pressure processing technology and equipment evolution: A review. Journal of Engineering Science and Technology Review, 8, 75–83. https://doi.org/10.25103/jestr.085.11

Elez-Martínez, P., Soliva-Fortuny, R. C., & Martín-Belloso, O. (2006). Comparative study on shelf life of orange juice processed by high intensity pulsed electric fields or heat treatment. European Food Research and Technology, 222, 321. https://doi.org/10.1007/s00217-005-0073-3

Fabroni, S., Amenta, M., Timpanaro, N., & Rapisarda, P. (2010). Supercritical carbon dioxide-treated blood orange juice as a new product in the fresh fruit juice market. Innovative Food Science & Emerging Technologies, 11, 477–484. https://doi.org/10.1016/j.ifset.2010.02.004

Fadl, M., & Liu, S. (2014). A comprehensive review on applications of ohmic heating (OH). Renewable and Sustainable Energy Reviews, 39, 262–269. https://doi.org/10.1016/j.rser.2014.07.061

Farkas, D. F., & Hoover, D. G. (2000). High pressure processing. Journal of Food Science, 65, 47–64. https://doi.org/10.1111/j.1750-3841.2000.tb00618.x

Ferrario, M., Guerrero, S., & Alzamora, S. M. (2014). Study of pulsed light-induced damage on Saccharomyces cerevisiae in apple juice by flow cytometry and transmission electron microscopy. Food and Bioprocess Technology, 7, 1001–1011. https://doi.org/10.1007/s11947-013-1121-9

Ferrentino, G., & Spilimbergo, S. (2011). High pressure carbon dioxide pasteurization of solid foods: Current knowledge and future outlooks. Trends in Food Science & Technology, 22(8), 427–441. https://doi.org/10.1016/j.tifs.2011.04.009

Ferrentino, G., Calliari, N., Bertucco, A., & Spilimbergo, S. (2014). Validation of a mathematical model for predicting high pressure carbon dioxide inactivation kinetics of Escherichia coli spiked on fresh cut carrot. The Journal of Supercritical Fluids, 85, 17–23. https://doi.org/10.1016/j.supflu.2013.10.015

Ferreira, S., Machado, L., Pereira, R. N., & Vicente, A. A. (2021). Unraveling the nature of ohmic heating effects in structural aspects of whey proteins — The impact of electrical and electrochemical effects. Innovative Food Science and Emerging Technologies, 74, (102831). https://doi.org/10.1016/j.ifset.2021.102831

Fleury, C., Savoire, R., Harscoat-Schiavo, C., Hadj-Sassi, A., & Subra-Paternault, P. (2018). Optimization of supercritical CO2 process to pasteurize dietary supplement: Influencing factors and CO2 transfer approach. The Journal of Supercritical Fluids, 141, 240–251. https://doi.org/10.1016/j.supflu.2018.01.009

Gasperi, F., Aprea, E., Biasioli, F., Carlin, S., Endrizzi, I., Pirretti, G., & Spilimbergo, S. (2009). Effects of supercritical CO2 and N2O pasteurisation on the quality of fresh apple juice. Food Chemistry, 115, 129–136. https://doi.org/10.1016/j.foodchem.2008.11.078

Gayán, E., Serrano, M. J., Monfort, S., Álvarez, I., & Condón, S. (2012). Combining ultraviolet light and mild temperatures for the inactivation of Escherichia coli in orange juice. Journal of Food Engineering, 113, 598–605. https://doi.org/10.1016/J.JFOODENG.2012.07.018

Gómez-López, V. M., Koutchma, T., & Linden, K. (2012). Chapter 8—Ultraviolet and pulsed light processing of fluid foods. In Novel thermal and non-thermal technologies for fluid foods (pp. 185–223). Academic Press, San Diego. https://doi.org/10.1016/j.tifs.2020.09.008

Gómez-López, V., Ragaert, P., Debevere, J., & Devlieghere, F. (2007). Pulsed light for food decontamination: A review. Trends in Food Science & Technology, 18, 464–473. https://doi.org/10.1016/j.tifs.2007.03.010

Gómez, P. L., Welti-Chanes, J., & Alzamora, S. M. (2011). Hurdle technology in fruit processing. Annual Review of Food Science and Technology, 2(1), 447–465. https://doi.org/10.1146/annurev-food-022510-133619

Guevara, M., Tapia, M. S., & Gómez-López, V. M. (2012). Microbial inactivation and quality of guava and passion fruit nectars treated by UV-C light. Food and Bioprocess Technology, 5, 803–807. https://doi.org/10.1007/s11947-011-0537-3

Heinz, V., Toepfl, S., & Knorr, D. (2003). Impact of temperature on lethality and energy efficiency of apple juice pasteurization by pulsed electric fields treatment. Innovative Food Science and Emerging Technologies, 4, 167–175. https://doi.org/10.1016/S1466-8564(03)00017-1

Huang, H. W., Hsu, C. P., Yang, B. B., & Wang, C. Y. (2014). Potential utility of high-pressure processing to address the risk of food allergen concerns. Comprehensive Reviews in Food Science and Food Safety, 13. https://doi.org/10.1111/1541-4337.12045

Icier, F. (2012). Ohmic heating of fluid foods. https://doi.org/10.1016/B978-0-12-381470-8.00011-6

Jiménez-Sánchez, C., Lozano-Sánchez, J., Segura-Carretero, A., & Fernández-Gutiérrez, A. (2017a). Alternatives to conventional thermal treatments in fruit-juice processing. Part 1: Techniques and applications. Critical Reviews in Food Science and Nutrition, 57, 501–523. https://doi.org/10.1080/10408398.2013.867828

Jiménez-Sánchez, C., Lozano-Sánchez, J., Segura-Carretero, A., & Fernández-Gutiérrez, A. (2017b). Alternatives to conventional thermal treatments in fruit-juice processing. Part 2: Effect on composition, phytochemical content, and physicochemical, rheological, and organoleptic properties of fruit juices. Critical Reviews in Food Science and Nutrition, 57(3), 637–652. https://doi.org/10.1080/10408398.2014.914019

Kernou, O.-N., Belbahi, A., Amir, A., Bedjaoui, K., Kerdouche, K., Dairi, S., Aoun, O., Madani, K. (2021). Effect of sonication on microwave inactivation of Escherichia coli in an orange juice beverage. Journal of Food Process Engineering, 44(5). https://doi.org/10.1111/jfpe.13664

Keyser, M., Muller, I. A., Cilliers, F. P., Nel, W., & Gouws, P. A. (2008). Ultraviolet radiation as a non-thermal treatment for the inactivation of microorganisms in fruit juice. Innovative Food Science and Emerging Technologies, 9, 348–354. https://doi.org/10.1016/j.ifset.2007.09.002

Koutchma, T., Popović, V., Ros-Polski, V., & Popielarz, A. (2016). Effects of ultraviolet light and high-pressure processing on quality and health-related constituents of fresh juice products. Comprehensive Reviews in Food Science and Food Safety, 15, 844–867. https://doi.org/10.1111/1541-4337.12214

Kozempel, M. F., Annous, B. A., Cook, R. D., Scullen, O. J., & Whiting, R. C. (1998). Inactivation of microorganisms with microwaves at reduced temperatures. Journal of Food Protection, 61(5), 582–585. https://doi.org/10.4315/0362-028x-61.5.582

Lee, J. Y., Kim, S. S., & Kang, D. H. (2015). Effect of pH for inactivation of Escherichia coli O157:H7, Salmonella typhimurium and Listeria monocytogenes in orange juice by ohmic heating. LWT - Food Science and Technology, 62. https://doi.org/10.1016/j.lwt.2015.01.020

Ma, Y., Hu, X., Chen, J., Zhao, G., Liao, X., Chen, F., Wu, J., & Wang, Z. (2010). Effect of UHP on enzyme, microorganism and flavor in cantaloupe (Cucumis melo L.) juice. Journal of Food Process Engineering, 33, 540–553. https://doi.org/10.1111/j.1745-4530.2008.00289.x

Maftei, N. A., Ramos-Villarroel, A. Y., Nicolau, A. I., Martín-Belloso, O., & Soliva-Fortuny, R. (2014). Influence of processing parameters on the pulsed-light inactivation of Penicillium expansum in apple juice. Food Control, 41, 27–31. https://doi.org/10.1016/J.FOODCONT.2013.12.023

Mak, P. P., Ingham, B. H., & Ingham, S. C. (2001). Validation of apple cider pasteurization treatments against Escherichia coli O157:H7, Salmonella, and Listeria monocytogenes. Journal of Food Protection, 64(11), 1679–1689. https://doi.org/10.4315/0362-028X-64.11.1679

Marszałek, K., Skąpska, S., Woźniak, L., & Sokołowska, B. (2015). Application of supercritical carbon dioxide for the preservation of strawberry juice: Microbial and physicochemical quality, enzymatic activity and the degradation kinetics of anthocyanins during storage. Innovative Food Science & Emerging Technologies, 32, 101–109. https://doi.org/10.1016/j.ifset.2015.10.005

Mercali, G. D., Gurak, P. D., Schmitz, F., & Marczak, L. D. (2015). Evaluation of non-thermal effects of electricity on anthocyanin degradation during ohmic heating of jaboticaba (Myrciaria cauliflora) juice. Food Chemistry, 171, 200–205. https://doi.org/10.1016/j.foodchem.2014.09.006

Millan-Sango, D., Garroni, E., Farrugia, C., Van Impe, J. F. M., & Valdramidis, V. P. (2016). Determination of the efficacy of ultrasound combined with essential oils on the decontamination of Salmonella inoculated lettuce leaves. Food Science and Technology, 73, 80–87. https://doi.org/10.1016/j.lwt.2016.05.039

Miller, F. A., & Silva, C. L. M. (2012). Thermal Treatment Effects in Fruit Juices. https://doi.org/10.1201/b12088.In:RodriguesS,FernandesFAN,editors.Advancesinfruitprocessingtechnologies.e-bookedition.BocaRaton,Fla.:CRCPress.p.363-83.ISBN:978-1-4398-5153-1

Murtaza, A., Iqbal, A., Linhu, Z., Liu, Y., Xu, X., Pan, S., & Hu, W. (2019). Effect of high-pressure carbon dioxide on the aggregation and conformational changes of polyphenol oxidase from apple (Malus domestica) juice. Innovative Food Science & Emerging Technologies, 54, 43–50. https://doi.org/10.1016/j.ifset.2019.03.001

Niu, L., Li, D., Huang, W., & Liao, X. (2019). Quality changes of orange juice after DPCD treatment. Journal of Food Quality. https://doi.org/10.1155/2019/6897583

Palaniswamy, P., Varadharaju, N., Kennedy, Z., Malathi, D., & Shridar, B. (2016). Non-thermal inactivation of Escherichia coli in pineapple juice by pulsed light treatment. International Journal of Food and Fermentation Technology, 6, 57. https://doi.org/10.5958/2277-9396.2016.00027.1

Pataro, G., Munoz, A., Palgan, I., et al. (2011). Bacterial inactivation in fruit juices using a continuous flow pulsed light (PL) system. Food Research International (Ottawa, Ont.), 44(6), 1642–1648. https://doi.org/10.1016/j.foodres.2011.04.048

Pei, L., Hou, S., Wang, L., & Chen, J. (2018). Effects of high hydrostatic pressure, dense phase carbon dioxide, and thermal processing on the quality of Hami melon juice. Journal of Food Process Engineering, 41. https://doi.org/10.1111/jfpe.12828

Pellicer, J. A., & Gómez-López, V. M. (2017). Pulsed light inactivation of horseradish peroxidase and associated structural changes. Food Chemistry, 237, 632–637. https://doi.org/10.1016/j.foodchem.2017.05.151

Pereira, R. N., & Vicente, A. A. (2010). Environmental impact of novel thermal and non-thermal technologies in food processing. Food Research International, 43(7), 1936–1943. https://doi.org/10.1016/j.foodres.2009.09.013

Perrut, M. (2012). Sterilization and virus inactivation by supercritical fluids (a review). The Journal of Supercritical Fluids, 66, 359–371. https://doi.org/10.1016/j.supflu.2011.07.007

Petruzzi, L., Campaniello, D., Speranza, B., Corbo, M. R., Sinigaglia, M., & Bevilacqua, A. (2017). Thermal treatments for fruit and vegetable juices and beverages: A literature overview. Comprehensive Reviews in Food Science and Food Safety, 16, 668–691. https://doi.org/10.1111/1541-4337.12270

Plaza, L., Sánchez-Moreno, C., De Ancos, B., Elez-Martínez, P., Martín-Belloso, O., & Cano, M. P. (2011). Carotenoid and flavone content during refrigerated storage of orange juice processed by high-pressure, pulsed electric fields and low pasteurization. LWT - Food Science and Technology, 44, 834–839. https://doi.org/10.1016/j.lwt.2010.12.013

Plaza, M., Marshall, M. R., & Rouseff, R. L. (2015). Volatile composition and aroma activity of guava puree before and after thermal and dense phase carbon dioxide treatments. Journal of Food Science, 80, 2. https://doi.org/10.1111/1750-3841.12736

Porębska, I., Sokołowska, B., Skąpska, S., & Rzoska, S. J. (2017). Treatment with high hydrostatic pressure and supercritical carbon dioxide to control Alicyclobacillus acidoterrestris spores in apple juice. Food Control, 73, 24–30. https://doi.org/10.1016/j.foodcont.2016.06.005

Qazalbash, U. R., Aadil, R., Madni, G., & Bekhit, A. (2018). The impact of nonthermal technologies on the microbiological quality of juices: A review. Comprehensive Reviews in Food Science and Food Safety, 17, 437–457. https://doi.org/10.1111/1541-4337.12336

Rastogi, N. K. (2013). “Introduction” in Recent developments in high pressure processing of foods (pp. 1–7). Springer US.

Rodriguez-Gonzalez, O., Buckow, R., Koutchma, T., & Balasubramaniam, V. M. (2015). Energy requirements for alternative food processing technologies—Principles, assumptions, and evaluation of efficiency. Comprehensive Reviews in Food Science and Food Safety, 14, 536–554. https://doi.org/10.1111/1541-4337.12142

Salazar-González, C., San Martín-González, M. F., López-Malo, A., et al. (2012). Recent studies related to microwave processing of fluid foods. Food and Bioprocess Technology, 5, 31–46. https://doi.org/10.1007/s11947-011-0639-y

Salazar-González, C. Y., Martin-Gonzalez, M. F., Vergara-Balderas, F. T., López-Malo, A., & Sosa-Morales, M. E. (2014). Physical-Chemical and Microbiological Stability during Refrigerated Storage of Microwave-Pasteurized Guava Nectar. https://doi.org/10.14355/FMFI.2014.03.006

Sánchez-Moreno, C., Plaza, L., Elez-Martinez, P., De Ancos, B., Martín-Belloso, O., & Cano, M. P. (2005). Impact of high pressure and pulsed electric fields on bioactive compounds and antioxidant activity of orange juice in comparison with traditional thermal processing. Journal of Agricultural and Food Chemistry, 53, 4403–4409. https://doi.org/10.1021/jf048839b

Siemer, C., Toepfl, S., & Heinz, V. (2014). Inactivation of Bacillus subtilis spores by pulsed electric fields (PEF) in combination with thermal energy — I. Influence of process- and product parameters. Food Control, 39, 163–171. https://doi.org/10.1016/j.foodcont.2013.10.025

Silva, E. K., Meireles, M. A. A., & Saldaña, M. D. A. (2020). Supercritical carbon dioxide technology: A promising technique for the non-thermal processing of freshly fruit and vegetable juices. Trends in Food Science and Technology, 97, 381–390. https://doi.org/10.1016/j.tifs.2020.01.025

Singh, R. P., & Heldman, D. R. (2001). Introduction to food engineering. Academic Press.

Spilimbergo, S., Elvassore, N., & Bertucco, A. (2002). Microbial inactivation by high-pressure. The Journal of Supercritical Fluids, 22, 55–63. https://doi.org/10.1016/S0896-8446(01)00106-1

Stefanini, R., Ronzano, A., Borghesi, G., & Vignali, G. (2021). Benefits and effectiveness of high pressure processing on cheese: A ricotta case study. International Journal of Food Engineering. https://doi.org/10.1515/ijfe-2021-0023

Tang, Y., Jiang, Y., Jing, P., & Jiao, S. (2021). Dense phase carbon dioxide treatment of mango in syrup: Microbial and enzyme inactivation, and associated quality change. Innovative Food Science & Emerging Technologies, 70, 102688. https://doi.org/10.1016/j.ifset.2021.102688

Timmermans, R., Mastwijk, H., Knol, J., Quataert, M. C. J., Vervoort, L., der Plancken, V., & Iesel & Hendrickx, Marc & Matser, A.M. (2011). Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice. Part I: Impact on overall quality attributes. Innovative Food Science & Emerging Technologies, 12, 235–243. https://doi.org/10.1016/j.ifset.2011.05.001

Toepfl, S., Heinz, V., & Knorr, D. (2007). High intensity pulsed electric fields applied for food preservation. Chemical Engineering and Processing: Process Intensification, 46(6), 537–546. https://doi.org/10.1016/j.cep.2006.07.011

Toepfl, S. (2012). Pulsed electric field food processing — Industrial equipment design and commercial applications. Stewart Postharvest Review, 8, 1–7. https://doi.org/10.2212/spr.2012.2.4

Toledo, R. T. (2007). Fundamentals of food process engineering (3rd ed.). Springer.

Torabian, G., Bahramian, B., Zambon, A., Spilimbergo, S., Adil, Q., Schindeler, A., Valtchev, P., & Dehghani, F. (2018). A hybrid process for increasing the shelf life of elderberry juice. The Journal of Supercritical Fluids, 140, 406–414. https://doi.org/10.1016/j.supflu.2018.07.023

Tremarin, A., Brandão, T., & Silva, C. (2016). Inactivation kinetics of Alicyclobacillus acidoterrestris in apple juice submitted to ultraviolet radiation. Food Control, 73. https://doi.org/10.1016/j.foodcont.2016.07.008

Uemura, K., & Isobe, S. (2003). Developing a new apparatus for inactivating Bacillus subtilis spore in orange juice with a high electric field AC under pressurized conditions. Journal of Food Engineering, 56, 325–329. https://doi.org/10.1016/S0260-8774(02)00157-7

Valero, M., Micol, V., Saura, D., Munoz, N., Lorente, J., & Marti, N. (2010). Comparison of antimicrobial treatments for citrus juices. In H. David (Ed.), Plant Sciences Reviews (p. 63–74). S.R. Nova Pvt. Ltd., Bangalore, India.

Van Impe, J., Smet, C., Tiwari, B., Greiner, R., Ojha, S., Stulić, V., Vukušić, T., & Režek Jambrak, A. (2018). State of the art of nonthermal and thermal processing for inactivation of micro-organisms. Journal of Applied Microbiology, 125, 16–35. https://doi.org/10.1111/jam.13751

Vervoort, L. V., der Plancken, I., Grauwet, T., Timmermans, R. A. H., Mastwijk, H. C., Matser, A. M., Hendrickx, M. E., & van Loey, A. (2011). Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice: Part II: Impact on specific chemical and biochemical quality parameters. Innovative Food Science and Emerging Technologies, 12(4), 466–477. https://doi.org/10.1016/j.ifset.2011.06.003

Vollmer, K., Santarelli, S., Vásquez-Caicedo, A. L., et al. (2020). Non-thermal processing of pineapple (Ananas comosus [L.] Merr.) juice using continuous pressure change technology (PCT): Effects on physical traits, microbial loads, enzyme activities, and phytochemical composition. Food and Bioprocess Technology, 13, 1833–1847. https://doi.org/10.1007/s11947-020-02520-y

Wahia, H., Zhou, C., Fakyaode, O. A., Amanor-Atiemoh, R., Zhang, L., Taiye, M. A., Zhang, J., Xu, B., Zhang, R., & Ma, H. (2021). Quality attributes optimization of orange juice subjected to multi-frequency thermosonication: Alicyclobacillus acidoterrestris spore inactivation and applied spectroscopy ROS characterization. Food Chemistry, 361, 130108. https://doi.org/10.1016/j.foodchem.2021.130108

Walkling-Ribeiro, M., Noci, F., Cronin, D., Lyng, J., & Morgan, D. (2010). Shelf life and sensory attributes of a fruit smoothie-type beverage processed with moderate heat and pulsed electric fields. Lebensmittel-Wissenschaft Und-Technologie, 43, 1067–1073. https://doi.org/10.1016/j.lwt.2010.02.010

Wang, L., Pan, J., Xie, H., Yang, Y., Zhou, D., & Zhu, Z. (2012). Pasteurization of fruit juices of different ph pH values by combined high hydrostatic pressure and carbon dioxide. Journal of Food Protection, 75, 1873–1877. https://doi.org/10.4315/0362-028X.JFP-12-127

Witt, J., Siemer, C., Bostelmann, A., & Toepfl, S. (2021). Juice preservation by pulsed electric fields. https://doi.org/10.1016/B978-0-12-815781-7.00026-3

Yildiz, S., Pokhrel, P. R., Unluturk, S., & Barbosa-Cánovas, G. V. (2021). Changes in quality characteristics of strawberry juice after equivalent high pressure, ultrasound, and pulsed electric fields processes. Food Engineering Reviews, 13, 601–612. https://doi.org/10.1007/s12393-020-09250-z

Yusi, S., Danshi, Z., Pushun, X., Tian, C., Xuehui, C., He, L., & Jianrong, L. (2021). Effects of temperature-controlled ultrasound treatment on sensory properties, physical characteristics and antioxidant activity of cloudy apple juice. LWT, 142, 111030. https://doi.org/10.1016/j.lwt.2021.111030

Zhang, H. Q. (2007). Electrical properties of foods. In G. V. Barbosa-Canovas (Ed.), Food Engineering. Encyclopedia of Life Support Systems (EOLSS) (vol. 1, pp. 115–125). Oxford, UK: Eolss Publishers.

Zhao, W., Sun, Y., Ma, Y., & Zhao, X. (2019). Dense phase carbon dioxide treatment of tomato juice: Effect on physico-chemical properties, phenolic composition, lycopene isomerisation and in vitro bioaccessibility. International Journal of Food Science and Technology, 54(5). https://ifst.onlinelibrary.wiley.com/doi/epdf/10.1111/ijfs.14042

Zou, H., Lin, T., Bi, X., Zhao, L., Wang, Y., & Liao, X. (2016). Comparison of high hydrostatic pressure, high-pressure carbon dioxide and high-temperature short-time processing on quality of mulberry juice. Food and Bioprocess Technology, 9, 217–231. https://doi.org/10.1007/s11947-015-1606-9

Acknowledgements

Special thanks are dedicated to all members of the Science and Technology Commission (STC) of the International Fruit and Vegetable Juice Association (IFU) for their valuable contribution to the development of this study.

Funding

Open access funding provided by Università degli Studi di Parma within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vignali, G., Gozzi, M., Pelacci, M. et al. Non-conventional Stabilization for Fruit and Vegetable Juices: Overview, Technological Constraints, and Energy Cost Comparison. Food Bioprocess Technol 15, 1729–1747 (2022). https://doi.org/10.1007/s11947-022-02772-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02772-w