Abstract

This study evaluated efficacy of pressurized argon (Ar) treatments in preserving quality of fresh-cut cucumbers. Cucumber cubs were, respectively, treated with 0.5 MPa Ar, 1.0 MPa Ar, 1.5 MPa Ar and 1.5 MPa air for 1 h at 20 °C and without pressurized treatment (control) and then stored at 4 °C and 90 % relative humidity (RH) for 12 days. Physiological, textural, chemical, and microbial attributes were measured at 1–2-day intervals. Results indicated that pressurized Ar treatments inhibited respiration, water loss, softening, chlorophyll degradation, and color change. The treatments also reduced loss of ascorbic acid and soluble solids. Treated cucumbers carried significantly less microbial population as indicated by total plate counts of yeasts and molds. Therefore, it was concluded that pressurized Ar treatment was beneficial to preserve quality of fresh-cut cucumbers.

Similar content being viewed by others

Introduction

As consumers are increasingly becoming aware of quality and nutritional value of foods, demand for fresh or fresh-cut fruits and vegetables is increasing. However, shelf life of fresh-cut products is usually limited by their quality deterioration during storage. Hence, it is essential that food processors provide safe, nutritionally wholesome, and maintained natural texture and flavor of fresh-cut products as much as possible. A series of technologies has been conducted for extending the shelf life of fresh-cut fruits and vegetables. Mild heat treatment has been used for fresh-cut produce application (McKellar et al. 2004; Koukounaras et al. 2008; Roura et al. 2008; Lemoine et al. 2009; Silveira et al. 2011; Siddiq et al. 2013). For example, Koukounaras et al. (2008) treated fresh-cut peach with short-term heat treatment at 50 °C for 10 min. They found that this heat treatment was effective in keeping good visual quality of fresh-cut peach during storage at 5 °C in modified atmosphere packaging. Hot air treatment (48 °C for 3 h) has also been shown effective in reducing senescence of fresh-cut broccoli during storage at 0 °C (Lemoine et al. 2009). However, heat treatment inevitably leads to loss of nutritional components and softening of fresh-cut produce (Abreu et al. 2003; Sgroppo and Pereyra 2009; Alegria et al. 2012). Ultraviolet-C radiation (UV-C) treatments have been employed as an alternative to thermal treatments for killing microorganisms, thus retaining the quality of fresh-cut fruits and vegetables (Fonseca and Rushing 2006; Gonzalez-Aguilar et al. 2007; Kasim et al. 2008; Artes-Hernandez et al. 2010; Manzocco et al. 2011b; Du et al. 2012). However, there are some disadvantages of UV light on fresh-cut fruits and vegetables. For example, UV irradiation might cause surface browning of fresh-cut fruits and vegetables (Gomez et al. 2010; Manzocco et al. 2011a; Pan and Zu 2012). In addition, UV light treatment can lead to modification of flavor and pigments (Artes-Hernandez et al. 2010; Manzocco et al. 2011a). As an alternative sanitizing technology, ozone is generally recognized as safe (GRAS) in the United States for food contact applications (Zhang et al. 2005). Owing to its strong sterilization function, ozone has been applied to reduce microbial populations and extend the shelf life of some fresh-cut fruits and vegetables (Zhang et al. 2005; Selma et al. 2008; Bermúdez-Aguirre and Barbosa-Cánovas 2013). For example, treatment of whole bell peppers (Capsicu mannuum) with continuously ozonated (at 2 ppm) water resulted in Listeria innocua decrease (Alexandre et al. 2011). It was also reported that ozone treatment at a flow rate of 8 ± 0.2 ml/s for up to 20 min was effective in maintaining nutritional properties of fresh-cut banana and pineapple (Alothman et al. 2010). However, an obvious disadvantage of ozone as a sanitizer is its poor stability in the presence of organic matter (Bermúdez-Aguirre and Barbosa-Cánovas 2013).

In recent years, inert gas-based food preservation technology has been successfully used to preserve freshness of fresh-cut fruits and vegetables (Zhang et al. 2001). When inert gases such as xenon (Xe) and argon (Ar) are dissolved in water under certain pressure, water molecules form a cage of polyhedral structure that can hold inert gas molecules, known as the clathrate hydrate (Linga et al. 2007; Yang et al. 2010). Cage-like hydrate formation alters the combined structure of water molecules in fruits and vegetables. Oshita et al. (2000) studied the effect of Xe treatment (0.6 MPa, 298 K) on relaxation time of water in fresh-cut broccoli tissue. Compared with that of control samples, the relaxation time of water in fresh-cut broccoli treated with Xe was shorter. When fresh-cut broccoli was stored under Xe-mixed air with Xe partial pressure of 0.45 MPa at 293 K, there was neither water loss nor visible browning of fresh-cut broccoli surface that was attributed to the formation of structured water resulting from dissolution of Xe. This suggested that mobility of water in fruits and vegetables can be greatly restricted due to the formation of clathrate hydrate. The technology of structured water was found to be effective in extending vase life of cut carnations treated with Xe at 0.5 MPa for 24 h (Oshita et al. 1996). Compared to that of control carnations, there was no respiration peak during storage. Withering of control carnations (constant room temperature at 293 K) was observed at 10 days of storage. However, there was still no withering in carnations treated by Xe at the end of 14 days of storage. Encouragingly, both Xe and Ar are chemically stable and they do not have an adverse effect in human (Ronald 2001; Zhang et al. 2001; EU 2012; Wu et al. 2012c). Thus, the technology of clathrate hydrate is a useful alternative for extending the shelf life of fruits and vegetables. Currently, this technology is at the exploratory stage in the fresh-cut fruits and vegetables industry, while there are very few relevant reports in the world (Oshita et al. 1996; Shan et al. 2008; Zhang et al. 2008). However, there is little information available on the effect of pressurized Ar on the quality of fresh-cut cucumber.

In this context, the objectives of this research were to study the effect of pressurized Ar on the quality of fresh-cut cucumber in cold storage. The effects of pressurized Ar on the storage quality parameters such as color, chlorophyll, ascorbic acid, soluble solids, firmness, loss of water and soluble solids, respiration rate, and microbial quality were measured.

Materials and Methods

Materials

Fresh cucumbers (Cucumis sativus L.) were purchased from a local farm in the neighborhood of Jiangnan University and transported to our laboratory. Cucumbers were sorted to remove damaged and defective fruit.

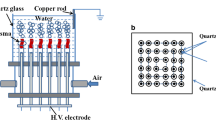

Sample Preparation and Processing

Whole cucumbers were cleaned with deionized water and sliced into 5-cm-long quarters with a sharp knife in a clean room maintained at 4 °C. Subsequently, fresh-cut cucumbers were washed with sodium hypochlorite (100 μL L−1 NaClO, pH 6.5) for 2 min and washed six times with sterile water. Then, these samples were gently centrifuged (110g at 4 °C for 1 min) in order to remove the water used in washing. They were further cut into small pieces with thickness of 2 cm and then placed into pressure vessels and subjected to pressurized Ar.

According our previous study (Zhan 2005), the treatments were divided into four groups: (1) control: without pressurized treatment, (2) 1.5 MPa air: treatment with pressurized air at 1.5 MPa and 20 °C for 1 h, (3) 0.5 MPa Ar: treatment with pressurized Ar at 0.5 MPa and 20 °C for 1 h, (4) 1.0 MPa Ar: treatment with pressurized Ar at 1.0 MPa and 20 °C for 1 h, and (5) 1.5 MPa Ar: treatment with pressurized Ar at 1.5 MPa and 20 °C for 1 h. Ar used in the experiments was purchased from Air Liquide (China), and the price of Ar is approximately US$0.0757/ft3 that is about the same as that of nitrogen. Under the same experimental condition, the cost of Ar is about the same as that of nitrogen (US$2.67 × 10−3 per experiment).

Fresh-cut cucumbers were enclosed in a stainless steel pressure chamber (effective inner volume = 1 L) at 20 °C. The air initially included in the chamber was eliminated from the chamber by a vacuum pump and the pressure of air in the chamber was maintained at 1.01 kPa. Then, the chamber was flushed with Ar or air to about 101.325 kPa. Subsequently, samples were pressurized by a plunger pump to the designed pressure. The time taken for the pressure to reach the target was approximately 80–120 s. After holding that pressure for 1 h at 20 °C, it took about 90–180 s to drop to about 101.325 kPa. Fresh-cut cucumbers after treatments of pressurized Ar, pressurized air, and control were placed in a polypropylene box (178 mm × 126 mm × 35 mm). Finally, these polypropylene boxes were sealed with 35-μm polypropylene films. The permeability of films at 23 °C and 90 % relative humidity (RH) for water vapor, oxygen, and carbon dioxide was 94.96 g mm/m2/22 h/atm, 0.026 mL/m2/22 h/atm, and 0.104 mL/m2/22 h/atm, respectively. All of these samples were stored at 4 °C and 90 % RH for 12 days. Three replicates were used per treatment.

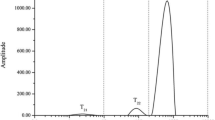

Respiration Rate

Respiration rate was determined as recommended by Ansorena et al. (2011). Cucumber samples (100 g each), taken from each treatment listed above every day, were placed in individual 1,000-mL airtight containers for 2 h at 4 °C. Then, a 5-mL gas sample was taken and injected into gas chromatographs (GC-2010, Shimadzu, Co., Japan). The gas chromatography (GC) settings for the detection of CO2 were as follows: thermal conductivity detector (TDC), Poropak N column, input port temperature of 80 °C, detector temperature of 80 °C, column temperature of 50 °C, and carrier gas (hydrogen) flow rate of 35 mL/min. The measurement of respiration rate per treatment was made in triplicate.

Water Loss and Firmness

Water loss of cucumbers was determined with three replicates per treatment (three cucumber slices per replicate) by the difference in mass of the sample before and after storage and expressed in wet basis (percent). Firmness was measured as the maximum force (N) required to puncture the flesh at a speed of 5 mm s−1 to a depth of 10 mm (Mao et al. 2007). A texture analyzer (TA-XT2i, Godalming, UK) fitted with a 5-mm-diameter stainless steel cylindrical probe was used for this purpose. The flesh firmness was measured on three samples of cucumbers randomly selected from each treatment.

Color and Chlorophyll Content

The flesh color of cucumber samples was measured with a Konica Minolta color difference meter (CR-400, Minolta, Tokyo, Japan) that provided CIE L*, a*, and b* values (Ansorena et al. 2011). L* represents the lightness of the color sample, a* represents the green–red color range, and b* represents the yellow–blue color range. In this study, b* was used to evaluate color quality. The b* value of flesh color of nine randomly selected cucumber slices from each treatment was measured every 2 days.

The chlorophyll contents of fresh-cut cucumbers were determined according to the method proposed by Zhang et al. (2008). Fresh-cut cucumbers (5 g) were homogenized with 20 mL of 80 % acetone in a tissue homogenizer (DS-1, Shanghai, China) at 2,000g (relative centrifugal force) for 30 s. The mixture was filtered through four layers of cheesecloth and finally centrifuged at 2,000g (relative centrifugal force) for 15 min. The absorbance of the filtered homogenate was measured at 647.0 and 664.5 nm on a UV spectrophotometer (UV-754, Shanghai Precision & Scientific Instrument Co., Ltd., Shanghai, China). The chlorophyll content was calculated using the following equation:

where A 647 is the absorbance of the filtered homogenate at 647.0 nm and A 664.5 is the absorbance of the filtered homogenate at 664.5 nm. Three replicates of samples were conducted for each treatment to measure the content of chlorophyll.

Soluble Solids and Ascorbic Acid Content

For determination of the soluble solid content, the cucumber samples were minced, crushed, and filtered through a Buchner filter by using two layers of filter papers. Then, the soluble solid content was measured with an Automatic Digital Abbe Refractometer, (WYA-Z, Shanghai Precision & Scientific Instrument Co., Ltd., China) and expressed as a percentage. Three replicates (three cucumber slices per replicate) of cucumbers samples were conducted for each treatment to measure the content of soluble solids.

Ascorbic acid content of the cucumber samples was determined according to the method described by Elezmartinez and Martinbelloso (2007). About 10 g of cucumbers was homogenized with 20 mL of metaphosphoric–acetic acid solution to extract ascorbic acid. After that, the mixture was centrifuged for 15 min at 2,000g (relative centrifugal force) and the supernatant was filtrated twice under vacuum in a volumetric flask. Before injecting the samples to high performance liquid chromatography (HPLC), each sample was filtrated through 0.45-μm cellulose acetate filter. The optimal HPLC conditions for quantitative determination were set as follows: Waters Spherisorb C18 column (150 × 4.6 mm, 5 μm) as stationary phase, 0.05 mol/L methanol–ammonium acetate solutions as mobile phase, 1 mL/min flow rate, UV detector (254 nm). Three replicates (three cucumber slices per replicate) of cucumbers samples were conducted for each treatment to measure the content of ascorbic acid.

Microbiological Analysis

Psychrophilic bacteria, yeast, and molds were used as microbial indices. Each sample of 25 g was placed in 225-mL sterile saline solution (0.2 % Tween 80) and rolled slowly up and down 30 times. Appropriate dilutions were prepared in the sterile saline solution. Subsequently, surviving microbial populations on fresh-cut cucumbers were evaluated on appropriate culture media (Koide and Shi 2007; Campaniello et al. 2008; Alegre et al. 2011).

Statistical Analysis

All data were processed by analysis of variance (ANOVA) and reported as mean ± standard deviation of three replicates. Data analysis was carried out by an ANOVA using SAS 8.0 software (SAS Institute Inc., NC, USA), with mean separation by paired t tests and significant differences established at P < 0.05.

Results and Discussion

Effect of Pressurized Ar on Respiration Rate

As an indicator of metabolic activity, respiration rate indicates potential shelf life of fruits and vegetables (Djioua et al. 2009). Changes in the respiration rate show the change occurring in physiological activity of samples. As can be seen from Fig. 1, compared to pressurized air treatment, the respiration rate of cucumbers treated with pressurized Ar was reduced significantly. This reduction was especially remarkable in the early stage of storage. In fresh-cut cucumbers treated with pressurized Ar, the same tendency was observed at the storage period. However, there were no significant differences found among pressurized Ar treatments. Compared to the negative role of 1.5-MPa air treatment on fresh-cut cucumbers, pressurized Ar treatment was effective in lowering the respiration rate of fresh-cut cucumbers. It was also found that, as indicated in Fig. 1, the respiration rate of the fresh-cut cucumbers subjected to 1.5 MPa Ar was higher than that of the samples subjected to 1.0 MPa Ar. This might be because high pressure at 1.5 MPa induced changes in the structure of the products that resulted in altered physicochemical properties, leading to enhanced metabolisms (Perera et al. 2010; Rastogi 2010). Overall, the respiration rate in the samples subjected to pressurized Ar was lower compared to that of the samples subjected to pressurized air and the control samples. Similarly, Zhang et al. (2008) reported that the respiration rates of asparagus spears could be reduced after the mixture treatment of compressed (1.1 MPa absolute) Ar and Xe (2:9 in partial pressure). It was also found that high pressure Ar treatment could play an active role in inhibiting the respiration rate of pineapple wedges during storage at 4 °C (Wu et al. 2012d). According to Rahman et al. (2002) and our previous research (Zhang et al. 2008; Meng et al. 2012; Wu et al. 2012a, b, c, d), suppression of the respiration rate in fresh-cut produce treated with high-pressure Ar might be due to dissolution of Ar into intracellular water in produce, leading to decrease of enzyme activities and mobility of intracellular water, and therapy restraining the metabolisms.

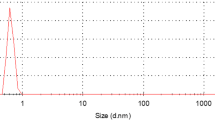

Effect of Pressurized Ar on Water Loss and Firmness

Water loss values of cucumbers treated with pressurized Ar and stored for 12 days are presented in Fig. 2a. As can be seen from Fig. 2a, the pressurized Ar treatments significantly reduced the water loss in cucumbers during the entire storage period. The loss of water was highest in the samples treated with 1.5 MPa air among all the treated samples during the entire test period. In contrast, the loss of water in the sample treated with pressurized Ar was lower than that of control sample (without pressurized treatment). Furthermore, the effect of Ar pressure on the extent of water loss in cucumbers was different depending on the applied pressure. For example, the water loss in samples treated with 0.5, 1.0, and 1.5 MPa Ar pressure were 3.27, 2.4, and 2.96 %, respectively, at 12 days of storage. These observations suggest that pressurized Ar treatment is an effective way of lowering or controlling the water loss in fresh agricultural products such as cucumbers. Similarly, Zhang et al. (2008) reported that asparagus spears treated for 24 h with mixtures of Ar and Xe could be kept in good quality for 12 days at 4 °C. According to their results, both the Ar and Xe individually or in mixed form were effective in minimizing the loss of water in asparagus spears. The preservative effect of the pressurized inert gas is attributed to the locking of water molecules by hydrogen bonds as a consequence of formation of gas hydrates when Ar and Xe penetrate into the tissues of fresh vegetable such as asparagus spears or cabbages (Makino et al. 2006). Previously, the relaxation time of protons in intracellular water of broccoli was investigated by Oshita et al. (2000). They suggested that the formation of structured water due to dissolution of Xe to be the reason due to which neither loss of water or visible browning occurred in the stored broccoli.

Consumer preference of cucumbers, to a great extent, is determined by their textural firmness (Dhall et al. 2011). Because of this reason, the textural firmness is commonly used as one of the most important indices evaluating cucumber quality. As shown in Fig. 2b, the firmness of the samples treated with 1.5 MPa air decreased rapidly with increase in storage time. In contrast, decrease in the firmness of pressurized Ar-treated cucumbers was lower than that in control samples. For example, compared to the decrease by 72 % in the firmness of control sample at the end of 12 days of storage, the firmness of cucumbers treated with pressurized Ar at 0.5 MPa, 1.0 MPa, and 1.5 MPa decreased by 48.3, 41.4, and 51.7 %, respectively, when stored for 12 days. It was also found that, as indicated in Fig. 2b, the firmness of the fresh-cut cucumbers subjected to 1.5 MPa Ar was lower than that of the samples subjected to 1.0 MPa Ar. This might be because high pressure at 1.5 MPa induced changes in the structure of the products that resulted in altered physicochemical properties and an initial loss of texture, probably due to loss of turgor pressure (De Roeck et al. 2010; Perera et al. 2010; Rastogi 2010). Overall, these results show that the application of pressurized Ar can delay the softening of texture in cucumbers during storage. Consistent with these findings, Zhang et al. (2008) reported that the structure of asparagus spears remained unchanged after treatment with a compressed mix of Ar and Xe.

Effect of Pressurized Ar on Color and Chlorophyll Content

Color in cucumbers is one of the most important quality parameters to evaluate its storage quality. It also influences, to a great extent, whether or not consumers prefer the stored product. Discoloration of fresh-cut cucumbers is one of the most common quality defects occurring during storage and is affected by storage environment. As shown in Fig. 3a, all the stored samples show an increase in b* during storage. Development of discoloration (as indicated by increase in b*) was more serious in samples subjected to 1.5 MPa air than that cucumbers treated with pressurized Ar (0.5 MPa, 1.0 MPa, and 1.5 MPa). There were no significant differences (p > 0.05) in b* among the samples treated with Ar at three pressure levels within the first 6 days. However, the difference in b* of pressurized Ar-treated samples (at different pressure levels) was significant (p < 0.05) when the samples were stored longer than 6 days. In contrast, the increase in b* of fresh-cut cucumbers treated with 1.5 MPa Ar was more than that of samples treated with 1.0 MPa Ar. This might be attributed to unsuitable pressure that could lead to disruption of cell walls and membranes, resulting in the mixing of enzymes and substrates in the disrupted plant tissue (Krebbers et al. 2002; Perera et al. 2010). Overall, pressurized Ar has the potential of minimizing or lowering color change. This might be due to the fact that the pressurized Ar could be capable of slowing down the conversion of chlorophyll to yellow-olive-colored pheophytin in the cucumber flesh (Krebbers et al. 2002). These findings agreed with our earlier finding that the chlorophyll content of asparagus spears treated with compressed Xe and Ar was preserved for a longer time (Zhang et al. 2008).

As the green pigment in cucumbers, chlorophyll plays an important role in maintaining the visual quality of fresh-cut cucumbers. When chlorophyll is decomposed, it leads to the development of yellowness in the products that reduces their sensory appeal and market value (Barrett et al. 2010). As shown in Fig. 3b, all samples showed a decrease in chlorophyll content during storage. Compared to the samples treated with pressurized air, the chlorophyll content was significantly higher (p < 0.05) in cucumbers treated with pressurized Ar. There were no significant differences (p > 0.05) in chlorophyll content among the samples treated with Ar at three pressure levels within the first 4 days. However, the difference in chlorophyll content of pressurized Ar-treated samples (at different pressure levels) was significant (p < 0.05) when the samples were stored longer than 6 days. In contrast, the increase in chlorophyll content of fresh-cut cucumbers treated with 1.5 MPa Ar was higher than that of the samples treated with 1.0 MPa Ar. This might be attributed to the fact that the disruption of cell walls and membranes could lead to the mixing of enzymes (lipoxygenase, peroxidase, or chlorophyllase) and substrates in the disrupted cucumbers subjected to unsuitable pressure, resulting in the increase of chlorophyll degradation (Krebbers et al. 2002; Perera et al. 2010). Overall, pressurized Ar was capable of slowing down the breakdown of chlorophyll in the cucumber flesh. Similarly, Zhang et al. (2008) observed that chlorophyll in asparagus treated with mixtures of compressed (1.1 MPa absolute) Ar and Xe was preserved better than control during storage at 4 °C.

Effect of Pressurized Ar on Ascorbic Acid and Soluble Solid Content

Changes of ascorbic acid content in samples subjected to different treatments are shown in Fig. 4a. When the fresh-cut cucumber samples were treated with 1.5 MPa air, oxygen (approximately 21 % of the atmosphere) in the chamber was also compressed. High partial pressure of oxygen might induce the disruption of the cell membrane in fresh-cut cucumbers, resulting in the exposure of nutritional constituents to oxygen during storage. As shown in this figure, the ascorbic acid content decreased with storage time for all treatments. However, the reduction of ascorbic acid content in the pressurized Ar-treated samples was smaller than that in the samples subjected to pressurized air. For example, at the end of 12 days of storage, the retention of ascorbic acid in the pressurized air-treated samples was 34.2 %. However, in the same storage duration, the retention values of ascorbic acid were 46.8, 67.8, and 56.9 % in cucumbers treated with Ar at 0.5 MPa, 1.0 MPa, and 1.5 MPa, respectively. This might be due to the fact that pressurized Ar could play a positive role of inhibiting the respiration of fresh-cut cucumbers, restraining enzyme activities and mobility of intracellular water (Rahman et al. 2002; Zhang et al. 2008; Meng et al. 2012; Wu et al. 2012d), and maintaining cell membrane integrity( Zhang et al. 2008; Meng et al. 2012; Wu et al. 2012a). Furthermore, there might be micropores remaining in samples after treating by pressurized Ar, which helped in retarding the physiological metabolism (Zhang et al. 2008; Wu et al. 2012a). As shown in Fig. 4b, the soluble solid content of fresh-cut cucumbers treated with pressurized Ar (1.0 and 1.5 MPa) changed very little during the first 4 days of storage. The extent of decrease in the soluble solid contents of the treated samples between the fifth and eighth days of storage was significantly higher than that in the first 4 days. In contrast, soluble solid content of samples treated with air at 1.5 MPa reduced more quickly than that of the pressurized Ar treatments. As seen in Fig. 4b, the decrease in soluble solid content in control samples was higher than the decrease of soluble solids in pressurized Ar-treated samples. This might be related to the lower consumption of soluble sugars (Beckles 2012) during storage following pressurized Ar treatment. Furthermore, pressurized air treatment with the presence of oxygen might accelerate the oxidative degradation of soluble solids. Thus, the application of pressurized Ar is conducive in controlling the loss of soluble solids during storage.

Effect of Pressurized Ar on Microbial Population

Microbial load is a major quality criterion determinant of the shelf life of fresh-cut fruit. Injury stress due to operations such as peeling, cutting, shredding, or slicing greatly increase risk of microbial development (Aguayo et al. 2004). The initial population of psychrophilic bacteria was approximately 3.27 log CFU/g. As shown in Table 1, when the samples were treated with pressurized Ar, the bacterial population was lower than that of control with increase in the storage time. However, higher microbial population was found in samples treated with pressurized air compared to that of control. Overall, the population of psychrophilic bacteria in the samples treated with pressurized Ar was lower compared to that of the samples treated with pressurized air and the control samples. This suggested that pressurized Ar could inhibit the growth of psychrophilic bacteria in fresh-cut cucumbers.

The initial loads of yeast and molds of fresh-cut cucumbers were approximately ∼ 2.45 log CFU/g. As shown in Table 2, when the samples were treated with pressurized Ar, the increase in the yeast and molds counts were decreased compared to that of control with the increase in storage time. However, higher population of mold and yeast was found in samples treated with pressurized air compared to that of control. Overall, the population of yeast and molds in the samples treated with pressurized Ar was lower compared to that of the samples treated with pressurized air and the control samples. Previously, it was proved that Ar had an inactivation accelerating effect within the low-temperature and low-pressure region where hydrophobic hydration generally arises (Fujii et al. 2002). Similarly, Wu, Zhang, and Adhikari (2012b) reported that the high pressure (Ar + Xe) mixed treatment could enhance resistance against infection of E. coli or S. cerevisiae in fresh-cut apples and pineapples, attributing to enhancement of wound healing ability. The inhibitory effect of pressurized Ar on psychrophilic bacteria, mold, and yeast might be attributed to the reduced mobility of water and the remaining micropores after the treatment process could play an active role in retarding the growth of microorganisms (Zhang et al. 2008; Meng et al. 2012; Wu et al. 2012a).

Conclusions

The application of pressurized inert gas (Ar) treatments was found effective in maintaining the quality (water loss, firmness, soluble solids, chlorophyll contents, and ascorbic acid contents) characteristics of fresh-cut cucumbers and inhibiting microbial growth during storage at 4 °C. In addition, the respiration rate of fresh-cut cucumbers was reduced by the application of pressurized Ar at test levels. Pressurized air at 1.5 MPa showed a negative effect on fresh-cut cucumbers. Overall, pressurized Ar treatment at 1.0 MPa was superior to other pressurized treatments in terms of the quality characteristics of fresh-cut cucumbers.

References

Abreu, M., Beirão-da-Costa, S., Gonçalves, E. M., Beirão-da-Costa, M. L., & Moldão-Martins, M. (2003). Use of mild heat pre-treatments for quality retention of fresh-cut ‘Rocha’ pear. Postharvest Biology and Technology, 30(2), 153–160.

Aguayo, E., Escalona, V., & Artés, F. (2004). Quality of fresh-cut tomato as affected by type of cut, packaging, temperature and storage time. European Food Research and Technology, 219(5), 492–499.

Alegre, I., Vinas, I., Usall, J., Anguera, M., & Abadias, M. (2011). Microbiological and physicochemical quality of fresh-cut apple enriched with the probiotic strain Lactobacillus rhamnosus GG. Food Microbiology, 28(1), 59–66.

Alegria, C., Pinheiro, J., Duthoit, M., Gonçalves, E. M., Moldão-Martins, M., & Abreu, M. (2012). Fresh-cut carrot (cv. Nantes) quality as affected by abiotic stress (heat shock and UV-C irradiation) pre-treatments. LWT- Food Science and Technology, 48(2), 197–203.

Alexandre, E. M. C., Santos-Pedro, D. M., Brandão, T. R. S., & Silva, C. L. M. (2011). Influence of aqueous ozone, blanching and combined treatments on microbial load of red bell peppers, strawberries and watercress. Journal of Food Engineering, 105(2), 277–282.

Alothman, M., Kaur, B., Fazilah, A., Bhat, R., & Karim, A. A. (2010). Ozone-induced changes of antioxidant capacity of fresh-cut tropical fruits. Innovative Food Science & Emerging Technologies, 11(4), 666–671.

Ansorena, M. R., Marcovich, N. E., & Roura, S. I. (2011). Impact of edible coatings and mild heat shocks on quality of minimally processed broccoli (Brassica oleracea L.) during refrigerated storage. Postharvest Biology and Technology, 59(1), 53–63.

Artes-Hernandez, F., Robles, P. A., Gomez, P. A., Tomas-Callejas, A., & Artes, F. (2010). Low UV-C illumination for keeping overall quality of fresh-cut watermelon. Postharvest Biology and Technology, 55(2), 114–120.

Barrett, D. M., Beaulieu, J. C., & Shewfelt, R. (2010). Color, flavor, texture, and nutritional quality of fresh-cut fruits and vegetables: Desirable levels, instrumental and sensory measurement, and the effects of processing. Critical Review in Food Science Nutrition, 50(5), 369–389.

Beckles, D. M. (2012). Factors affecting the postharvest soluble solids and sugar content of tomato (Solanum lycopersicum L.) fruit. Postharvest Biology and Technology, 63(1), 129–140.

Bermúdez-Aguirre, D., & Barbosa-Cánovas, G. V. (2013). Disinfection of selected vegetables under nonthermal treatments: Chlorine, acid citric, ultraviolet light and ozone. Food Control, 29(1), 82–90.

Campaniello, D., Bevilacqua, A., Sinigaglia, M., & Corbo, M. R. (2008). Chitosan: Antimicrobial activity and potential applications for preserving minimally processed strawberries. Food Microbiology, 25(8), 992–1000.

De Roeck, A., Mols, J., Duvetter, T., Van Loey, A., & Hendrickx, M. (2010). Carrot texture degradation kinetics and pectin changes during thermal versus high-pressure/high-temperature processing: A comparative study. Food Chemistry, 120(4), 1104–1112.

Dhall, R. K., Sharma, S. R., & Mahajan, B. V. C. (2011). Effect of shrink wrap packaging for maintaining quality of cucumber during storage. Journal of Food Science and Technology, 49(4), 495–499.

Djioua, T., Charles, F., Lopez-Lauri, F., Filgueiras, H., Coudret, A., Freire, M., Jr., et al. (2009). Improving the storage of minimally processed mangoes (Mangifera indica L.) by hot water treatments. Postharvest Biology and Technology, 52(2), 221–226.

Du, W. X., Avena-Bustillos, R. J., Breksa, A. P., & McHugh, T. H. (2012). Effect of UV-B light and different cutting styles on antioxidant enhancement of commercial fresh-cut carrot products. Food Chemistry, 134(4), 1862–1869.

Elezmartinez, P., & Martinbelloso, O. (2007). Effects of high intensity pulsed electric field processing conditions on vitamin C and antioxidant capacity of orange juice and gazpacho, a cold vegetable soup. Food Chemistry, 102(1), 201–209.

EU (2012). Current EU approved additives and their E Numbers. Food Standards Agency, London, UK. Available at www.food.gov.uk/policy-advice/additivesbranch/enumberlist#h7. Accessed at: 14 March 2012.

Fonseca, J. M., & Rushing, J. W. (2006). Effect of ultraviolet-C light on quality and microbial population of fresh-cut watermelon. Postharvest Biology and Technology, 40(3), 256–261.

Fujii, K., Ohtani, A., Watanabe, J., Ohgoshi, H., Fujii, T., & Honma, K. (2002). High-pressure inactivation of Bacillus cereus spores in the presence of argon. International Journal of Food Microbiology, 72(3), 239–242.

Gomez, P. L., Alzamora, S. M., Castro, M. A., & Salvatori, D. M. (2010). Effect of ultraviolet-C light dose on quality of cut-apple: Microorganism, color and compression behavior. Journal of Food Engineering, 98(1), 60–70.

Gonzalez-Aguilar, G. A., Villegas-Ochoa, M. A., Martinez-Tellez, M. A., Gardea, A. A., & Ayala-Zavala, J. F. (2007). Improving antioxidant capacity of fresh-cut mangoes treated with UV-C. Journal of Food Science, 72(3), 197–202.

Kasim, M. U., Kasim, R., & Erkal, S. (2008). UV-C treatments on fresh-cut green onions enhanced antioxidant activity, maintained green color and controlled ‘telescoping’. Journal of Food Agriculture & Environment, 6(3–4), 63–67.

Koide, S., & Shi, J. (2007). Microbial and quality evaluation of green peppers stored in biodegradable film packaging. Food Control, 18(9), 1121–1125.

Koukounaras, A., Diamantidis, G., & Sfakiotakis, E. (2008). The effect of heat treatment on quality retention of fresh-cut peach. Postharvest Biology and Technology, 48(1), 30–36.

Krebbers, B., Matser, A., Koets, M., & Van den Berg, R. (2002). Quality and storage-stability of high-pressure preserved green beans. Journal of Food Engineering, 54(1), 27–33.

Lemoine, M. L., Civello, P., Chaves, A., & Martínez, G. (2009). Hot air treatment delays senescence and maintains quality of fresh-cut broccoli florets during refrigerated storage. LWT- Food Science and Technology, 42(6), 1076–1081.

Linga, P., Kumar, R., & Englezos, P. (2007). Gas hydrate formation from hydrogen/carbon dioxide and nitrogen/carbon dioxide gas mixtures. Chemical Engineering Science, 62(16), 4268–4276.

Makino, Y., Kawahashi, M., Kuroki, S., Shinmura, T., Kawagoe, Y., & Oshita, S. (2006). Respiratory depression of shredded cabbage using xenon at atmospheric pressure. Agricultural Engineering International: the CIGR journal, 8, 1–11.

Manzocco, L., Da Pieve, S., Bertolini, A., Bartolomeoli, I., Maifreni, M., Vianello, A., et al. (2011a). Surface decontamination of fresh-cut apple by UV-C light exposure: Effects on structure, colour and sensory properties. Postharvest Biology and Technology, 61(2–3), 165–171.

Manzocco, L., Da Pieve, S., & Maifreni, M. (2011b). Impact of UV-C light on safety and quality of fresh-cut melon. Innovative Food Science & Emerging Technologies, 12(1), 13–17.

Mao, L., Lu, F., & Wang, G. (2007). Application of 1-methylcyclopropene reduces wound responses and maintains quality in fresh-cut apple. Asia Pacific Journal of Clinical Nutrition, 16(Suppl 1), 111–115.

McKellar, R. C., Odumeru, J., Zhou, T., Harrison, A., Mercer, D. G., Young, J. C., et al. (2004). Influence of a commercial warm chlorinated water treatment and packaging on the shelf-life of ready-to-use lettuce. Food Research International, 37(4), 343–354.

Meng, X., Zhang, M., & Adhikari, B. (2012). Extending shelf-life of fresh-cut green peppers using pressurized argon treatment. Postharvest Biology and Technology, 71, 13–20.

Oshita, S., Seo, Y., & Kawagoe, Y. (2000). Relaxation time of protons in intracellular water of broccoli. Agricultural Engineering International: The CIGR E, http://www.cigrjournal.org/index.php/Ejounral/article/viewFile/1040/1033 (last accessed 09.02.10).

Oshita, S., Seo, Y., Kawagoe, Y., Koreeda, K., & Nakamura, K. (1996). Extension of vase life of cut carnations by structured water. Acta Horticulturae (ISHS), 440, 657–662.

Pan, Y.-G., & Zu, H. (2012). Effect of UV-C radiation on the quality of fresh-cut pineapples. Procedia Engineering, 37, 113–119.

Perera, N., Gamage, T. V., Wakeling, L., Gamlath, G. G. S., & Versteeg, C. (2010). Colour and texture of apples high pressure processed in pineapple juice. Innovative Food Science & Emerging Technologies, 11(1), 39–46.

Rahman, M., Islam, A., Khair, A., & Bala, B. (2002). Effect of nonpolar gases on the storage of persimmon fruits (Diospyros khaki L.) at different temperatures. Pakistan Journal of Biological Sciences, 5(1), 84–87.

Rastogi, N. K. (2010). Effect of high-pressure food processing on physicochemical changes of foods. In S. Devahastin (Ed.), Physicochemical aspects of food engineering and processing (pp. 107–158). Boca Raton: CRC.

Ronald, V. (2001). Food additives in the European Union. In J. H. T. Iii, S. Salminen, L. A. Branen, & M. P. Davidson (Eds.), Food additives (pp. 1–89). NY: Marcel Dekker.

Roura, S. I., Pereyra, L., & del Valle, C. E. (2008). Phenylalanine ammonia lyase activity in fresh cut lettuce subjected to the combined action of heat mild shocks and chemical additives. LWT- Food Science and Technology, 41(5), 919–924.

Selma, M. V., Allende, A., Lopez-Galvez, F., Conesa, M. A., & Gil, M. I. (2008). Disinfection potential of ozone, ultraviolet-C and their combination in wash water for the fresh-cut vegetable industry. Food Microbiology, 25(6), 809–814.

Sgroppo, S. C., & Pereyra, M. V. (2009). Using mild heat treatment to improve the bioactive related compounds on fresh-cut green bell peppers. International Journal of Food Science and Technology, 44(9), 1793–1801.

Shan, L., Shan, M., Tian, Y., Zhang, M., & Zhan, Z. (2008). Effects of pressurized CO2/Xe/O2 mixture on the storage quality of asparagus (Asparagus officinalis L.) spear. Journal of Food Science and Biotechnology Advances, 27(4), 43–47.

Siddiq, M., Roidoung, S., Sogi, D. S., & Dolan, K. D. (2013). Total phenolics, antioxidant properties and quality of fresh-cut onions (Allium cepa L.) treated with mild-heat. Food Chemistry, 136(2), 803–806.

Silveira, A. C., Aguayo, E., Escalona, V. H., & Artés, F. (2011). Hot water treatment and peracetic acid to maintain fresh-cut Galia melon quality. Innovative Food Science & Emerging Technologies, 12(4), 569–576.

Wu, Z.-S., Zhang, M., & Adhikari, B. (2012a). Application of high pressure argon treatment to maintain quality of fresh-cut pineapples during cold storage. Journal of Food Engineering, 110(3), 395–404.

Wu, Z., Zhang, M., & Adhikari, B. (2012b). Effects of high pressure argon and xenon mixed treatment on wound healing and resistance against the growth of Escherichia coli or Saccharomyces cerevisiae in fresh-cut apples and pineapples. Food Control, 30(1), 265–271.

Wu, Z. S., Zhang, M., & Wang, S. (2012c). Effects of high pressure argon treatments on the quality of fresh-cut apples at cold storage. Food Control, 23(1), 120–127.

Wu, Z. S., Zhang, M., & Wang, S. J. (2012d). Effects of high-pressure argon and nitrogen treatments on respiration, browning and antioxidant potential of minimally processed pineapples during shelf life. Journal of the Science of Food and Agriculture, 92(11), 2250–2259.

Yang, L., Tulk, C. A., Klug, D. D., Chakoumakos, B. C., Ehm, L., Molaison, J. J., et al. (2010). Guest disorder and high pressure behavior of argon hydrates. Chemical Physics Letters, 485(1–3), 104–109.

Zhan, Z. G. (2005). Study on preservation of asparagus spears and cucumber by pretreatment with pressurized xenon. Master of sciences dissertation. China: Southern Yangtze University.

Zhang, D., Quantick, P. C., Grigor, J. M., Wiktorowicz, R., & Irven, J. (2001). A comparative study of effects of nitrogen and argon on tyrosinase and malic dehydrogenase activities. Food Chemistry, 72(1), 45–49.

Zhang, L., Lu, Z., Yu, Z., & Gao, X. (2005). Preservation of fresh-cut celery by treatment of ozonated water. Food Control, 16(3), 279–283.

Zhang, M., Zhan, Z., Wang, S., & Tang, J. (2008). Extending the shelf-life of asparagus spears with a compressed mix of argon and xenon gases. LWT- Food Science and Technology, 41(4), 686–691.

Acknowledgments

This research was financially supported by the National Natural Science Foundation of China (No. 30972058) and Niumag Corporation. The authors also like to acknowledge the State Key Laboratory of Food Science and Technology (Jiangnan University) and the School of Food Science and Technology (Jiangnan University) for permitting the use of processing and analytical instruments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, X., Zhang, M., Zhan, Z. et al. Changes in Quality Characteristics of Fresh-cut Cucumbers as Affected by Pressurized Argon Treatment. Food Bioprocess Technol 7, 693–701 (2014). https://doi.org/10.1007/s11947-013-1092-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-013-1092-x