Abstract

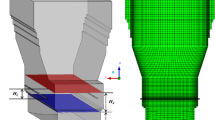

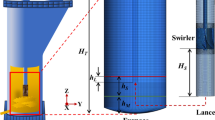

The Peirce–Smith (PS) converter is one of the pyrometallurgical copper smelting processes, in which the flow field in the converter has an important influence on production efficiency. In this study, a CFD simulation of the air–oil–water cold model with a ratio of 1:5 was adopted to investigate the gas–liquid–liquid three-phase flow characteristics. The effect of nozzle height on the flow field, velocity, phase, and wall shear stress have been described. The optimal nozzle height is 0.105–0.125 m, under which the flow field distributed uniformly and the gas–liquid mixing was sufficient. The shear stress on the lining wall above the nozzles is larger than in other places, so the nozzle height can be changed regularly during the injection process to make the lining near the nozzles be scoured evenly so prolonging the furnace service life. The optimal nozzle height for an industrial PS converter was suggested to be from 0.525 m to 0.625 m.

Similar content being viewed by others

References

Z. H. Liu, L. G. Xia, Miner. Process. Extr. Metall., 128, 117 (2019)

R. Sridhar, J.M. Toguri, and S. Simeonov, JOM 49, 48. (1997).

J. Vaarno, P. Jyrki, T. Ahokainen, and A. Jokilaakso, Appl. Math. Model. 22, 907. (1998).

A. Valencia, R. Paredes, M. Rosales, E. Godoy, and J. Ortega, Int. Commun. Heat Mass Transfer 31, 21. (2004).

K. Z. Song, A. Jokilaakso, Miner. Process. Extr. Metall. Rev., 1 (2020).

A.K. Hasanzadeh-Lileh, M. Halali, M. Askari, and M.T. Manzari, Chem. Prod. Process Model. 3, 1. (2008).

D.K. Chibwe, G. Akdogan, C. Aldrich, and R.H. Eric, Chem. Prod. Process Model. 6, 1. (2011).

X. Jiang, Z. Cui, M. Chen, and B. Zhao, Metall. Mater. Trans. B 50, 173. (2019).

L. Shui, X.D. Ma, Z.X. Cui, and B.J. Zhao, JOM 70, 2119. (2018).

L. Shui, Z.X. Cui, X.D. Ma, X. Jiang, M. Chen, Y. Xiang, and B.J. Zhao, JOM 70, 2065. (2018).

A. Almaraz, L. César, I. Arellano, M.A. Barrón, D. Jaramillo, F. Reyes, and G. Plascencia, Miner Eng. 56, 102. (2014).

X. Zhao, H.L. Zhao, L.F. Zhang, and L.Q. Yang, Int. J. Miner. Metall. Mater. 25, 37. (2018).

H.L. Zhao, X. Zhao, L.Z. Mu, L.F. Zhang, and L.Q. Yang, Int. J. Miner. Metall. Mater. 26, 1092. (2019).

H.L. Zhao, J.Q. Wang, F.Q. Liu, and H.Y. Sohn, Metall. Mater. Trans. B 52, 440. (2021).

A. Sokolichin, G. Eigenberger, A. Lapin, and A. Lübert, Chem. Eng. Sci. 52, 611. (1997).

J. Xiao, H.J. Yan, M. Schubert, S. Unger, L. Liu, E. Schleicher, U. Hampel, and J. Cent, South Univ. 26, 2068. (2019).

A. Sokolichin, G. Igenberger, A. Lapin, and A. Lübert, Chem. Eng. Sci. 52, 611. (1997).

Z.Y. Zhang, H.J. Yan, F.K. Liu, and J.M. Wang, Chin. J. Nonferrous. Met. 23, 1471. (2013).

P. Shao, and L. Jiang, Int. J. Mol. Sci. 20, 5757. (2019).

M. Annaland, N.G. Deen, and J. Kuipers, Chem. Eng. Sci. 60, 2999. (2005).

J. L. Zhang, Chin Nonferrous. Metall., 2, 11 (2017).

X.W. Wan, W.D. Yang, X. Tang, and B.J. Ma, Chin Nonferrous. Metall. 1, 40. (2007).

F. Qian, X.K. Duan, W.A. Yang, G.Q. Liu, and H.X. Li, Mater. Rep. 33, 3882. (2019).

A.A. Metelkin, O.Y. Sheshukov, M.V. Savelev, A.A. Kotlyarov, O.I. Shevchenko, and Y.A. Lysenko, Steel Transl. 48, 12. (2018).

M.M. Striplin Jr., J.M. Potts, and E.C. Marks, J. Electrochem. Soc. 106, 146. (1959).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51974018), the Guangxi Innovation-Driven Development Project (AA18242042-1), and the Fundamental Research Funds for the Central Universities (FRF-TP-19-016A3). The authors are also grateful to the reviewers for their arduous work in providing many pertinent comments and suggestions, which helped in improving the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, T., Xiao, Y., Zhou, Y. et al. Numerical Simulation of Nozzle Height on the Effect of Fluid Flow in a Peirce–Smith Converter. JOM 73, 2938–2945 (2021). https://doi.org/10.1007/s11837-021-04813-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04813-9