Abstract

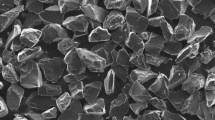

The effect of Li (2.0 wt%) addition on mechanical properties and ageing precipitation behavior of Al−3.0Mg−0.5Si was investigated by tensile test, dynamic elasticity modulus test, scanning electron microscopy (SEM), transmission electron microscopy (TEM) and high-resolution transmission electron microscopy (HRTEM) images. The results show that the tensile strength of the Li-containing alloy can be significantly improved; however, the ductility is sharply decreased and the fracture mechanism changes from ductile fracture to intergranular fracture. The elasticity modulus of the Li-containing alloy increases by 11.6% compared with the base alloy. The microstructure observation shows that the Li addition can absolutely change the precipitation behavior of the base alloy, and δ′-Al3Li phase becomes the main precipitates. Besides, β″-Mg2Si and δ′-Al3Li dual phases precipitation can be visibly observed at 170 °C ageing for 100 h, although the quantity of δ′-Al3Li phase is more than β″-Mg2Si phase. The width of the precipitate-free zone (PFZ) of the Li-containing alloy is much wider at the over-ageing state than the base alloy, which has a negative impact on the ductile and results in the decrease of elongation.

摘要

本文对比研究了添加 2.0 wt%Li 元素与不添加 Li 元素的 Al−3.0Mg−0.5Si 挤压合金的室温拉伸性 能、 动态弹性模量和时效析出行为. 结果表明, 添加 Li 元素在降低合金密度的同时, 还提高了合金的 强度和弹性模量, 但也导致合金的伸长率大幅度减小, 断裂机制从韧性断裂转变为沿晶断裂. 微观组 织观察显示, Li 元素的添加改变了合金的时效析出行为, δ′-Al3Li 相成为主要析出强化相. 含Li 合金在 170 °C 时效 100 h 后, 有明显的球状δ′-Al3Li 相和针状 β″-Mg2Si 相双相析出现象. 此外, 含 Li 合金过时 效状态下的无沉淀析出带宽度更大, 对合金的塑性产生不利影响, 造成伸长率下降.

Similar content being viewed by others

References

DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys [J]. Materials & Design, 2014, 56: 862–871. DOI: https://doi.org/10.1016/j.matdes.2013.12.002.

RIOJA R J, LIU J. The evolution of Al−Li base products for aerospace and space applications [J]. Metallurgical and Materials Transactions A, 2012, 43(9): 3325–3337. DOI: https://doi.org/10.1007/s11661-012-1155-z.

GUMBMANN E, GEUSER F D, SIGLI C, DESCHAMPS A. Influence of Mg, Ag and Zn minor solute additions on the precipitation kinetics and strengthening of an Al−Cu−Li alloy [J]. Acta Materialia, 2017, 133: 172–185. DOI: https://doi.org/10.1016/j.actamat.2017.05.029.

DENG Yan-jun, HUANG Guang-jie, CAO Ling-fei, WU Xiao-dong, HUANG Li. Effect of ageing temperature on precipitation of Al−Cu−Li−Mn−Zr alloy [J]. Journal of Central South University, 2018, 25: 1340–1349. DOI: https://doi.org/10.1007/s11771-018-3830-8.

LI Jin-feng, YE Zhi-hao, LIU Dan-yang, CHEN Yong-lai, ZHANG Xu-hu, XU Xiu-zhi, ZHENG Zi-qiao. Influence of pre-deformation on aging precipitation behavior of three Al−Cu−Li alloys [J]. Acta Metallurgica Sinica (English Letters), 2017, 30(2): 133–145. DOI: https://doi.org/10.1007/s40195-016-0519-6.

EL-ATY A A, XU Yong, GUO Xun-zhong, ZHANG Shi-hong, MA Yan, CHEN Da-yonng. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review [J]. Journal of Advanced Research, 2018, 10: 49–67. DOI: https://doi.org/10.1016/j.jare.2017.12.004.

MA Wei-ping, WANG Bao-yu, XIAO Wen-chao, YANG Xiao-ming, KANG Yi. Springback analysis of 6016 aluminum alloy sheet in hot V-shape stamping [J]. Journal of Central South University, 2019, 26: 524–535. DOI: https://doi.org/10.1007/s11771-019-4024-8.

CHBIHI A, VINCENT S, RIBIS J, TOFFOLON-MASCLET C, GARNIER J. Influence of plastic deformation on the precipitation sequence in an AA6061 alloy [J]. Journal of Materials Science, 2017, 52(10): 6063–6073. DOI: https://doi.org/10.1007/s10853-017-0845-8.

KOSHINO Y, KOZUKA M, HIROSAWA S, YASUHIRO A. Comparative and complementary characterization of precipitate microstructures in Al−Mg−Si(−Li) alloys by transmission electron microscopy, energy dispersive X-ray spectroscopy and atom probe tomography [J]. Journal of Alloys and Compounds, 2015, 622: 765–770. DOI: https://doi.org/10.1016/j.jallcom.2014.10.199.

MØRTSELL E A, MARIOARA C D, ANDERSEN S J, RINGDALEN I G, FRIIS J, WENNER S, RØYSET J, REISO O, HOLMESTAD R. The effects and behaviour of Li and Cu alloying agents in lean Al−Mg−Si alloys [J]. Journal of Alloys and Compounds, 2017, 699: 235–242. DOI: https://doi.org/10.1016/j.jallcom.2016.12.273.

HUANG Z W, SMALLMAN R E, LORETTO M H, WHITE J. Influence of lithium additions on precipitation and hardening of 6061 [J]. Materials Science and Technology, 1991, 7(3): 205–212. DOI: https://doi.org/10.1179/026708391790183385.

HUANG Z W, LORETTO M H, SMALLMAN R E, WHITE J. Mechanism of nucleation and precipitation in 6061-Li alloys [J]. Materials Science and Technology, 1994, 10: 869–878. DOI: https://doi.org/10.1179/026708394790163285.

CHEN R, HUANG Z, CHEN C Q, SHEN J Y, ZHANG Y G. Thermodynamic calculated and TEM observed microstructure of Al−Li−Mg−Si alloys [J]. Materials Science and Engineering A, 2000, 280(1): 146–150. DOI: https://doi.org/10.1016/S0921-5093(99)00681-4.

SHAMAS U D, KAMRAN J, TARIQ N H, HASAN B A, PETROV R H, BLIZNUK V, SHAMAS U Z. The synergistic effect of Li addition on microstructure, texture and mechanical properties of extruded Al−Mg−Si alloys [J]. Materials Chemistry and Physics, 2016, 174: 11–22. DOI: https://doi.org/10.1016/j.matchemphys.2016.02.029.

YANG Xiao-kun, XIONG Bai-qing, LI Xi-wu, YAN Li-zhen, LI Zhi-hui, ZHANG Yong-an, LIU Hong-wei, HUANG Shu-hui, YAN Hong-wei, WEN Kai. Microstructural evolution and phase transformation of Al−Mg−Si alloy containing 3% Li during homogenization [C]// CMC 2018: Physics and Engineering of Metallic Materials. Springer, 2019: 19–28. DOI: https://doi.org/10.1007/978-981-13-5944-6_3.

RIOJA R J. Fabrication methods to manufacture isotropic Al−Li alloys and products for space and aerospace applications [J]. Materials Science and Engineering A, 1998, 257(1): 100–107. DOI: https://doi.org/10.1016/S0921-5093(98)00827-2.

LAVERNIA E J, SRIVATSAN T S, MOHAMED F A. Strength, deformation, fracture behaviour and ductility of aluminium-lithium alloys [J]. Journal of Materials Science, 1990, 25(2): 1137–1158. DOI: https://doi.org/10.1007/BF00585420.

WANG S C, STARINK M J. Precipitates and intermetallic phases in precipitation hardening Al−Cu−Mg−(Li) based alloys [J]. International Materials Reviews, 2005, 50(4): 193–215. DOI: https://doi.org/10.1179/174328005X14357.

DING Li-peng, JIA Zhi-hong, NIE Jian-feng, WENG Yao-yao, CAO Ling-fei, CHEN Hou-wen, WU Xiao-zhi, LIU Qing. The structural and compositional evolution of precipitates in Al−Mg−Si−Cu alloy [J]. Acta Materialia, 2018, 145: 437–450. DOI: https://doi.org/10.1016/j.actamat.2017.12.036.

JIA Zhi-hong, DING Li-peng, CAO Ling-fei, SANDERS R, LI Shi-chen, LIU Qing. The influence of composition on the clustering and precipitation behavior of Al−Mg−Si−Cu alloys [J]. Metallurgical Materials Transactions A, 2017, 48(1): 459–473. DOI: https://doi.org/10.1007/s11661-016-3850-7.

WANG Y L, JIANG H C, LI Z M, YAN D S, ZHANG D, RONG L J. Two-stage double peaks ageing and its effect on stress corrosion cracking susceptibility of Al−Zn−Mg alloy [J]. Journal of Materials Science & Technology, 2018, 34(7): 1250–1257. DOI: https://doi.org/10.1016/j.jmst.2017.05.008.

ZHANG Xiao-long, ZHANG Liang, WU Guo-hua, SHI Chun-chang, ZHANG Jin-shuo. Influences of Mg content on the microstructures and mechanical properties of cast Al−2Li−2Cu−0.2Zr alloy [J]. Journal of Materials Science, 2019, 54(1): 791–811. DOI: https://doi.org/10.1007/s10853-018-2826-y.

DENG Yun-lai, YANG Jin-long, LI Si-yu, ZHANG Jin, ZHANG Xin-ming. Influence of Li addition on mechanical property and aging precipitation behavior of Al−3.5Cu−1.5Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1653–1658. DOI: https://doi.org/10.1016/S1003-6326(14)63237-4.

CHEN Xiao-xue, MA Xin-wu, XI Hua-kun, ZHAO Guo-qun, WANG Yong-xiao, XU Xiao. Effects of heat treatment on the microstructure and mechanical properties of extruded 2196 Al−Cu−Li alloy [J]. Materials & Design, 2020, 192: 108746. DOI: https://doi.org/10.1016/j.matdes.2020.108746.

ZHANG Jin, DENG Yun-lai, LI Si-yu, CHEN Ze-yu, ZHANG Xin-ming. Creep age forming of 2124 aluminum alloy with single/double curvature [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 1922–1929. DOI: https://doi.org/10.1016/S1003-6326(13)62678-3.

ZHU A W, STARKE E A. Strengthening effect of unshearable particles of finite site: A compu-ter experimental study [J]. Acta Materialia, 1999, 47(11): 3263–3269. DOI: https://doi.org/10.1016/S1359-6454(99)00179-2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(2016YFB0300802) supported by the National Key Research and Development Program of China

Contributors

YANG Xiao-kun provided the concept, analyzed the measured data and wrote the original draft; XIONG Bai-qing provided the concept and methodology; LI Xi-wu, YAN Li-zhen and WEN Kai reviewed and edited the draft; LI Zhi-hui and ZHANG Yong-an provided the concept and project administration; LI Ya-nan and LIU Hong-wei provided the resources and supervision.

Conflict of interest

YANG Xiao-kun, XIONG Bai-qing, LI Xi-wu, YAN Li-zhen, LI Zhi-hui, ZHANG Yong-an, LI Ya-nan, WEN Kai, LIU Hong-wei declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Yang, Xk., Xiong, Bq., Li, Xw. et al. Effect of Li addition on mechanical properties and ageing precipitation behavior of extruded Al−3.0Mg−0.5Si alloy. J. Cent. South Univ. 28, 2636–2646 (2021). https://doi.org/10.1007/s11771-021-4798-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4798-3

Key words

- Al−3.0Mg−0.5Si alloy

- Li addition

- microstructure

- ageing behavior

- mechanical properties

- dynamic elasticity modulus