Abstract

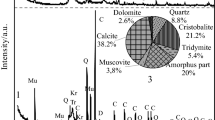

An innovative technology, nitric acid pressure leaching of limonitic laterite ores, was proposed by our research team. The HNO3 regeneration is considerable significance for the improvement of the proposed technology and its commercial application, but it has not been systematically investigated. Herein, regenerating HNO3 from Ca(NO3)2 solution with low-cost H2SO4, and simultaneous synthesis of fibrous CaSO4·2H2O by-products were studied. As a theoretical basis, the solubility of CaSO4·2H2O in HNO3 medium is studied. It is concluded that the solubility of CaSO4·2H2O increases with increasing temperature or increasing HNO3 concentration, which has considerable guiding significance for the subsequent experimental research and analysis. Then, the effects of various factors on the residual Ca2+ concentration of filtrate, the regenerated HNO3 concentration and the morphology of synthesized products are investigated using ICP-AES and SEM. And the effect mechanism is also analyzed. The results indicate the regenerated HNO3 concentration reaches 116 g/L with the residual Ca2+ concentration being 9.7 g/L at the optimum conditions. Moreover, fibrous CaSO4·2H2O by-products with high aspect ratios (length, 406.32 µm; diameter, 14.71 µm; aspect ratio, 27.62) can be simultaneously synthesized.

摘要

HNO3 再生对于褐铁型红土镍矿硝酸加压浸出技术的完善和工业应用意义重大。本文采用低成 本的H2SO4 从Ca(NO3)2 溶液中再生HNO3, 并同步制备CaSO4·2H2O 副产物。作为理论基础, 测定了 CaSO4·2H2O 在HNO3 介质中的溶解度。结果表明, CaSO4·2H2O 的溶解度随着温度的升高或HNO3 浓 度的增大而不断增大, 这对后续的实验研究和结果分析具有指导意义。借助电感耦合等离子体原子发 射光谱分析和扫描电子显微镜等检测手段考察了各因素对滤液残留Ca2+浓度、再生HNO3 浓度和产物 形貌的影响, 并分析了其影响机理。结果表明, 在最优条件下, 再生HNO3 浓度达116 g/L, 滤液残留 Ca2+浓度为9.7 g/L, 同步制备的CaSO4·2H2O 副产物具备高纵横比(长406.32 μm; 直径14.71 μm; 纵 横比27.62)。

Similar content being viewed by others

References

LIU Kui, CHEN Qi-yuan, HU Hui-ping, YIN Zhou-lan, WU Bo-ke. Pressure acid leaching of a Chinese laterite ore containing mainly maghemite and magnetite [J]. Hydrometallurgy, 2010, 104(1): 32–38. DOI: https://doi.org/10.1016/j.hydromet.2010.04.008.

SADYKHOV G B, ZABLOTSKAYA Y V, ANISONYAN K G, KHASANOV M S, OLYUNINA T V, GONCHAROV K V, KOP’EV D Y. Development of a new combined process for nickel and cobalt recovery from ferriferous laterite ores [J]. Russian Metallurgy (Metally), 2019, 2019(3): 197–203. DOI: https://doi.org/10.1134/S0036029519030108.

BOTELHO JUNIOR A B, DREISINGER D B, ESPINOSA D C R. A review of nickel, copper, and cobalt recovery by chelating ion exchange resins from mining processes and mining tailings [J]. Mining, Metallurgy & Exploration, 2018, 36: 199–213. DOI: https://doi.org/10.1007/s42461-018-0016-8.

MA Bao-zhong, WANG Cheng-yan, YANG Wei-jiao, YANG Bo, ZHANG Yong-lu. Selective pressure leaching of Fe (II)-rich limonitic laterite ores from Indonesia using nitric acid [J]. Minerals Engineering, 2013, 45: 151–158. DOI: https://doi.org/10.1016/j.mineng.2013.02.009.

MA Bao-zhong, YANG Wei-jiao, YANG Bo, WANG Cheng-yan, CHEN Yong-qiang, ZHANG Yong-lu. Pilot-scale plant study on the innovative nitric acid pressure leaching technology for laterite ores [J]. Hydrometallurgy, 2015, 155: 88–94. DOI: https://doi.org/10.1016/j.hydromet.2015.04.016.

MA Bao-zhong, XING Peng, WANG Cheng-yan, CHEN Yong-qiang, SHAO Shuang. A novel way to synthesize calcium sulfate whiskers with high aspect ratios from concentrated calcium nitrate solution [J]. Materials Letters, 2018, 219: 1–3. DOI: https://doi.org/10.1016/j.matlet.2018.02.025.

YANG Yu-rong, ZHANG Qing-jie, CAI Wei, YI Mei-gui, XIANG Lan. Formation and application of hierarchical calcium silicate-calcium sulfate whiskers [J]. Materials & Design, 2018, 146: 172–179. DOI: https://doi.org/10.1016/j.matdes.2018.03.018.

GUAN Qing-jun, SUN Wei, LIU Run-qing, YIN Zhi-gang, ZHANG Chen-hu. Preparation of α-calcium sulfate hemihydrate whiskers with high aspect ratios in presence of a minor amount of CuCl2·2H2O [J]. Journal of Central South University, 2018, 25(3): 526–533. DOI: https://doi.org/10.1007/s11771-018-3757-0.

TENG Wei-li, WANG Jin-shu, WU Jun-shu, DU Yu-cheng, JIA X J, LI Hong-yi, WANG Tian-ning. Rapid synthesis of alpha calcium sulfate hemihydrate whiskers in glycerol-water solution by using flue-gas-desulfurization gypsum solid waste [J]. Journal of Crystal Growth, 2018, 496: 24–30. DOI: https://doi.org/10.1016/j.jcrysgro.2018.05.008.

FAN Tao-tao, WANG Xiu-shan, GAO Yang, ZHANG Xiao-yuan. Investigating the interaction mechanism and effect of different calcium sulfate whiskers on performance of asphalt binder [J]. Construction and Building Materials, 2019, 224: 515–533. DOI: https://doi.org/10.1016/j.conbuildmat.2019.07.093.

QI Yun-fei, ZENG Chang-feng, WANG Chong-qing, KE Xue-bin, ZHANG Li-xiong. Continuous fabrication of calcium sulfate whiskers with adjustable aspect ratio in microdroplets [J]. Materials Letters, 2017, 194: 231–233. DOI: https://doi.org/10.1016/j.matlet.2017.02.066.

RABIZADEH T, STAWSKI T M, MORGAN D J, PEACOCK C L, BENNING L G. The effects of inorganic additives on the nucleation and growth kinetics of calcium sulfate dihydrate crystals [J]. Crystal Growth & Design, 2017, 17(2): 582–589. DOI: https://doi.org/10.1021/acs.cgd.6b01441.

RU Xiao-hong, MA Bao-guo, HUANG Jian, HUANG Yun. Phosphogypsum transition to α-calcium sulfate hemihydrate in the presence of omongwaite in NaCl solutions under atmospheric pressure [J]. Journal of the American Ceramic Society, 2012, 95(11): 3478–3482. DOI: https://doi.org/10.1111/j.1551-2916.2012.05429.x.

LUO Kang-bi, LI Chun-mei, XIANG Lan, LI Hu-ping, NING Ping. Influence of temperature and solution composition on the formation of calcium sulfates [J]. Particuology, 2010, 8(3): 240–244. DOI: https://doi.org/10.1016/j.partic.2010.01.005.

SONG Xing-fu, ZHANG Li-na, ZHAO Jing-cai, XU Yan-xia, SUN Ze, LI Ping, YU Jian-guo. Preparation of calcium sulfate whiskers using waste calcium chloride by reactive crystallization [J]. Crystal Research and Technology, 2011, 46(2): 166–172. DOI: https://doi.org/10.1002/crat.201000420.

FAN Hao, SONG Xing-fu, LIU Tian-jie, XU Yan-xia, YU Jian-guo. Effect of Al3+ on crystal morphology and size of calcium sulfate hemihydrate: Experimental and molecular dynamics simulation study [J]. Journal of Crystal Growth, 2018, 495: 29–36. DOI: https://doi.org/10.1016/j.jcrysgro.2018.05.013.

HOU S C, XIANG L. Influence of activity of CaSO4·2H2O on hydrothermal formation of CaSO4·0.5H2O whiskers [J]. Journal of Nanomaterials, 2013, 2013. DOI: https://doi.org/10.1155/2013/237828.

GUAN Bao-hong, YANG Li, FU Hai-lu, KONG Bao, LI Ting-ying, YANG Liu-chun. α-calcium sulfate hemihydrate preparation from FGD gypsum in recycling mixed salt solutions [J]. Chemical Engineering Journal, 2011, 174(1): 296–303. DOI: https://doi.org/10.1016/j.cej.2011.09.033.

JIAN Guang-ming, WANG Hao, CHEN Qiao-shan, ZHANG Xian-ming, WU Zhong-biao, GUAN Bao-hong. Preparation of alpha-calcium sulfate hemihydrate from FGD gypsum in chloride-free Ca(NO3)2 solution under mild conditions [J]. Fuel, 2016, 174: 235–241. DOI: https://doi.org/10.1016/j.fuel.2016.01.073.

WANG Xiao, YANG Liu-shuan, ZHU Xin-feng, YANG Jia-kuan. Preparation of calcium sulfate whiskers from FGD gypsum via hydrothermal crystallization in the H2SO4-NaCl-H2O system [J]. Particuology, 2014, 17: 42–48. DOI: https://doi.org/10.1016/j.partic.2013.12.001.

GUAN Qing-jun, TANG Hong-hu, SUN Wei, HU Yue-hua, YIN Zhi-gang. Insight into influence of glycerol on preparing α-CaSO4·½H2O from flue gas desulfurization gypsum in glycerol-water solutions with succinic acid and NaCl [J]. Industrial & Engineering Chemistry Research, 2017, 56: 9831–9838. DOI: https://doi.org/10.1021/acs.iecr.7b02067.

SUN Hong-juan, TAN Dao-yong, PENG Tong-jiang, LIANG Ya-qin. Preparation of calcium sulfate whisker by atmospheric acidification method from flue gas desulfurization gypsum [J]. Procedia Environmental Sciences, 2016, 31: 621–626. DOI: https://doi.org/10.1016/j.proenv.2016.02.112.

EL MOUSSAOUITI M, BOISTELLE R, BOUHAOUSS A, KLEIN J P. Crystallization of calcium sulphate hemihydrate in concentrated phosphoric acid solutions [J]. Chemical Engineering Journal, 1997, 68(2, 3): 123–130. DOI: https://doi.org/10.1016/S1385-8947(97)00116-2.

MAO Xiu-long, SONG Xing-fu, LU Gui-min, SUN Yu-zhu, XU Yan-xia, YU Jian-guo. Effects of metal ions on crystal morphology and size of calcium sulfate whiskers in aqueous HCl solutions [J]. Industrial & Engineering Chemistry Research, 2014, 53(45): 17625–17635. DOI: https://doi.org/10.1021/ie5030134.

MAO Xiu-long, SONG Xing-fu, LU Gui-min, SUN Yu-zhu, XU Yan-xia, YU Jian-guo. Control of crystal morphology and size of calcium sulfate whiskers in aqueous HCl solutions by additives: Experimental and molecular dynamics simulation studies [J]. Industrial & Engineering Chemistry Research, 2015, 54(17): 4781–4787. DOI: https://doi.org/10.1021/acs.iecr.5b00585.

MIAO Miao, FENG Xin, WANG Gang-ling, CAO Shao-mei, SHI Wen, SHI Li-yi. Direct transformation of FGD gypsum to calcium sulfate hemihydrate whiskers: Preparation, simulations, and process analysis [J]. Particuology, 2015, 19: 53–59. DOI: https://doi.org/10.1016/j.partic.2014.04.010.

AZIMI G, PAPANGELAKIS V G, DUTRIZAC J E. Modelling of calcium sulphate solubility in concentrated multi-component sulphate solutions [J]. Fluid Phase Equilibria, 2007, 260(2): 300–315. DOI: https://doi.org/10.1016/j.fluid.2007.07.069.

DUTRIZAC J E. Calcium sulphate solubilities in simulated zinc processing solutions [J]. Hydrometallurgy, 2002, 65(2, 3): 109–135. DOI: https://doi.org/10.1016/S0304-386X(02)00082-8.

RAHMATIA, GHOLAMIAN M, ROSTAMI S, AMIRPOUR M, SAFARIH, MOHAMMADI A H. An efficient model for estimation of gypsum (calcium sulfate di-hydrate) solubility in aqueous electrolyte solutions over wide temperature ranges [J]. Journal of Molecular Liquids, 2019, 281: 655–670. DOI: https://doi.org/10.1016/j.molliq.2019.02.077.

AZIMI G, PAPANGELAKIS V G, DUTRIZAC J E. Development of an MSE-based chemical model for the solubility of calcium sulphate in mixed chloride-sulphate solutions [J]. Fluid Phase Equilibria, 2008, 266(1, 2): 172–186. DOI: https://doi.org/10.1016/j.fluid.2008.01.027.

YANG Liu-chun, GUAN Bao-hong, WU Zhong-biao, MA Xian-fa. Solubility and phase transitions of calcium sulfate in KCl solutions between 85 and 100 °C [J]. Industrial & Engineering Chemistry Research, 2009, 48(16): 7773–7779. DOI: https://doi.org/10.1021/ie900372j.

BEHIJ S, HICHEM A, ROKBANI H R, M’NIF A. Solubility study of sodium, potassium and calcium sulfates and chlorides, in ammonia [J]. Russian Journal of Inorganic Chemistry, 2011, 56(6): 991–998. DOI: https://doi.org/10.1134/S0036023611060210.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item

Project(2182040) supported by the Beijing Natural Science Foundation, China; Projects(51674026, 51974025, U1802253) supported by the National Natural Science Foundation of China; Project(FRF-TT-19-001) supported by the Fundamental Research Funds for the Central Universities, China

Contributors

The overarching research goals were developed by WANG Cheng-yan and MA Bao-zhong. SHAO Shuang performed the experiments and collected the data. WANG Xin and ZHANG Wen-juan analyzed the measured data and the calculated results. The research activity planning and execution were managed by CHEN Yong-qiang. The initial draft of the manuscript was written by SHAO Shuang. MA Bao-zhong and WANG Cheng-yan reviewed and edited the manuscript.

Conflict of interest

SHAO Shuang, MA Bao-zhong, WANG Xin, ZHANG Wen-juan, CHEN Yong-qiang, and WANG Cheng-yan declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shao, S., Ma, Bz., Wang, X. et al. Nitric acid pressure leaching of limonitic laterite ores: Regeneration of HNO3 and simultaneous synthesis of fibrous CaSO4·2H2O by-products. J. Cent. South Univ. 27, 3249–3258 (2020). https://doi.org/10.1007/s11771-020-4463-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4463-2