Abstract

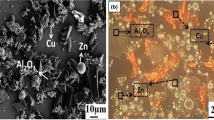

In order to improve the hot corrosion resistance of DZ125 alloy, Ce-Y modified aluminum coatings were prepared on DZ125 alloy by pack cementation process at 950 °C for 2 h. The microstructure, phase constitution and formation mechanism of the coatings were investigated. The hot corrosion behaviors of DZ125 alloy and the coatings in molten salt environment of 25%K2SO4+75%Na2SO4 (mass fraction) at 900 °C were studied. Results show that the obtained Al-Ce-Y coatings were mainly composed of Al3Ni2, Al3Ni and Cr7Ni3, with a thickness of about 120 μm. After hot corrosion test, DZ125 alloy suffered catastrophic hot corrosion and serious internal oxidation and internal sulfidation arose. Two layers of corrosion products formed on surfaces of DZ125 alloy, including the outer layer consisting of Cr2O3 and NiCr2O4, and the inner layer of Al2O3, Ni3S2 and Ni-base solid solution. After being coated with Al-Ce-Y coating, the hot corrosion resistance of DZ125 alloy is improved notably, due to the formation of a dense scale mainly consisting of Al-rich Al2O3 in the coating layer.

摘要

采用扩散渗方法在 DZ125 合金表面制备了 Al-Ce-Y 渗层。分析了渗层的组织结构和形成机制, 对比研究了 DZ125 合金基体及渗层在 900 °C 的 25%K2SO4+75%Na2SO4 熔盐(质量分数 wt. %)中的 热腐蚀行为,探讨了其腐蚀速率和腐蚀机理。结果表明:经 950 °C 保温 2 h 所制备的Al-Ce-Y 渗层厚 约 120 μm,主要由 Al3Ni2、Al3Ni 和少量 Cr7Ni3 相组成。在 K2SO4+Na2SO4 熔盐中,DZ125 合金腐蚀 产物膜分为两层,外层主要为 Cr2O3 和 NiCr2O4,内层主要为 Al2O3、Ni3S2 和镍基固溶体,内氧化和 内硫化是其失效的主要原因; Al-Ce-Y 渗层在热腐蚀的过程中,渗层表面形成了致密的富Al 的 Al2O3 膜层,显著提高了DZ125 合金的抗热腐蚀性能。

Similar content being viewed by others

References

YANG F B, JING Y H, LI D. Microstructure and mechanical property of MIM 418 superalloy [J]. Rare Metals, 2018, 37(1): 35–40. DOI: 10.1007/s12598-014-0419-8.

CHANG J X, WANG D, LIU X G, LOU L H, ZHANG J. Effect of rhenium addition on hot corrosion resistance of Ni-based single crystal superalloys [J]. Metallurgical and Materials Transactions, 2018, 49: 4343–4352. DOI: 10.1007/ s11661-018-4711-3.

ZHOU Hong-ming, HU Xue-yi, LI Jian. Corrosion behaviors and mechanism of electroless Ni-Cu-P/n-TiN composite coating [J]. Journal of Central South University, 2018, 25(6): 1350–1357. DOI: https://doi.org/10.1007/ s11771-018-3831-7.

LIU Zong-jie, ZHOU Chun-gen. Hot corrosion behavior of Si-Y-Co-modified aluminide coating exposed to NaCl+ Na2SO4 salt at 1173 K [J]. Oxidation of Metals, 2016, 85: 205–217. DOI: 10.1007/s11085-015-9599-3.

ZHOU W, ZHAO Y G, QIN Q D. A new way to produce Al-Cr coating on Ti alloy by vacuum fusing method and its oxidation resistance [J]. Materials Science and Engineering A, 2006, 430: 254–259. DOI: 10.1016/j.msea.2006.05.101.

KIM N H, SEONGHA O, LEE W S. Non-selenization method using sputtering deposition with a CuSe2 target for CIGS thin film [J]. Journal of the Korean Physical Society, 2012, 61(8): 1177–1180. DOI: 10.3938/jkps.61.1177.

LIN Nai-ming, ZHAO Lu-lu, LIU Qiang, ZOU Jiao-juan, XIE Rui-zhen, YUAN Shuo, LI Da-li, ZHANG Lu-xia, WANG Zhi-hua, LIU Xiao-ping, TANG Bin. Preparation of titanizing coating on AISI 316 stainless steel by pack cementation to mitigate surface damage: Estimations of corrosion resistance and tribological behavior[J]. Journal of Physics and Chemistry of Solids, 2019, 129: 387–400. DOI: 10.1016/j.jpcs.2019.01.029.

BISHOY A, PATRICK G, CHRISTIAN M. Erratum to: Temperature measurement challenges and limitations for in-flight particles in suspension plasma spraying [J]. Journal of Thermal Spray Technology, 2017, 26(4): 798–804. DOI: 10.1007/s11666-017-0543-8.

LIN Nai-ming, HUANG Xiao-bo, ZHANG Xiang-yu, FAN Ai-lin, QIN Lin, TANG Bin. In vitro assessments on bacterial adhesion and corrosion performance of TiN coating on Ti6Al4V titanium alloy synthesized by multi-arc ion plating [J]. Applied Surface Science, 2012, 258: 7047–7051. DOI: 10.1016/j.apsusc.2012.03.163.

STATHOKOSTOP D, CHALIAMPALISA D, TARANI E. Formation of the thermoelectric candidate chromium silicide by use of a pack-cementation process [J]. Journal of Electronic Materials, 2014, 43(10): 3733–3739. DOI: 10.1007/s11664-014-3100-y.

ZHANG Ping, GUO Xi-ping. A comparative study of two kinds of Y and Al modified silicide coatings on an Nb-Ti-Si based alloy prepared by pack cementation technique [J]. Corrosion Science, 2011, 53(12): 4291–4299. DOI: 10.1016/j.corsci.2011.08.040.

LIN N M, XIE F Q, ZHOU J. Microstructures and wear resistance of chromium coatings on P110 steel fabricated by pack cementation [J]. Journal of Central South University of Technology, 2010, 17: 1144–1162. DOI: 10.1007/s11771-010-0612-3.

LI Yong-quan, XIE Fa-qin, WU Xiang-qing, LI Xuan. Effects of Y2O3 on the microstructures and wear resistance of Si-Al-Y co-deposition coatings prepared on TiAl alloy by pack cementation technique [J]. Applied Surface Science, 2013, 278: 30–36. DOI: 10.1016/j.apsusc.2013.09.050.

LI Yong-quan, XIE Fa-qin, WU Xiang-qing. Microstructure and high temperature oxidation resistance of Si-Y co-deposition coatings prepared on a TiAl alloy by pack cementation process [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 803–807. DOI: 10.1016/S1003-6326(15)63666-4.

LI Yong-quan, XIE Fa-qin, WU xiang-qing. Si-Al-Y Co-deposition coatings prepared on Ti-Al alloy for enhanced high temperature oxidation resistance [J]. Journal of Wuhan University of Technology-Mater, 2018, 33(4): 959–966. DOI: 10.1007/s11595-018-1919-4.

HUNZIKER O, KU W. Drectional solidification and phase equilibria in the Ni-Al system [J]. Metallurgical and Materials Transactions A, 1999, 30: 3167–3172. DOI: 10.1007/s11661-999-0227-1.

XIANG Z D, DATTA P K. Aluminide coating formation on nickel-base superalloys by pack cementation process [J]. Journal of Materials science, 2001, 36: 5673–5682. DOI: 10.1023/a:1012534220165.

ZHANG J Z, YANG Z L, WEI K Y. Study of the catalysis and diffusion mechanism by rare earth (RE) elements during the thermo-chemical treatment [J]. Materials Review, 2006, 20: 223–225. DOI: 10.3321/j.issn:1005-023X.2006.z1.072

LI Xuan, GUO Xi-ping, QIAO Yan-qiang. Friction and wear behaviors of Nb-Ti-Si-Cr based ultrahigh temperature alloy and its Zr-Y jointly modified silicide coatings [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1892–1901. DOI: 10.1016/S1003-6326(16)64267-X.

WU Duo-li, JIANG Su-meng, QI Xiang, GONG Fan-jun, SUN Chao. Hot corrosion behavior of a Cr-modified aluminide coating on a Ni-based superalloy [J]. Acta Metallurgica Sinica, 2014, 276(4), 627–634. DOI: 10.1007/ s40195-014-0108-5.

ZHANG Ping, GUO Xi-pin. Y and Al modified silicide coatings on an Nb-Ti-Si based ultrahigh temperature alloy prepared by pack cementation process [J]. Surface and Coatings Technology, 2011, 206(2): 446–454. DOI: 10.1016/ j.surfcoat.2011.07.056.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51961003) supported by the National Natural Science Foundation of China; Project(NGY2018-148) supported by the Science and Technology Research of Ningxia Colleges, China; Project(NZ16083) supported by Key Program of Natural Science Foundation of Ningxia, China

Rights and permissions

About this article

Cite this article

Li, Yq., Li, Jl., Qin, C. et al. Microstructure and hot corrosion behavior of Al-Ce-Y coatings on DZ125 nickel-based alloy prepared by pack cementation process. J. Cent. South Univ. 27, 381–387 (2020). https://doi.org/10.1007/s11771-020-4303-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4303-4