Abstract

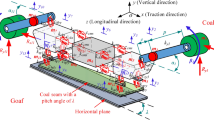

The impact of the load on the shearer is mainly transmitted through cutting part. In this paper, in order to get the vertical steering vibration characteristics of the cutting part of the drum shearer, the working condition of coal mining machine is simplified. A simplified vertical steering model and the simplified vibration model of the whole cutting part of shearer are established. The vertical steering vibration process of the cutting unit is simplified into a single freedom and one forced vibration system under harmonic excitation. The dynamic response of the cutting part under sine excitation is obtained by using Matlab/Simulink for modeling and simulation. The influence of the support rigidity and damping of the high oil cylinder on the vertical steering vibration characteristics of the cutting part is analyzed. The results show that the damping of the cylinder can reduce the vibration of the system and the stability of the swing process of cutting the part is improved.

摘要

采煤机负载对采煤机的振动冲击主要通过截割部进行传递。为得到滚筒式采煤机截割部的垂直 振动特性, 对采煤机工况进行合理简化, 建立了采煤机截割部垂直简化模型, 进而建立了采煤机截割 部整体机构的振动数学模型。将采煤机截割部垂直振动过程简化为在简谐激振力作用下的单自由受迫 振动系统, 运用Matlab/Simulink 进行建模仿真, 得到截割部在正弦激振下的垂直摆动动态响应, 分析 了调高油缸的支撑刚度与阻尼对截割部垂直振动特性的影响。结果表明, 增大调高油缸的阻尼可以减 轻系统的振动, 提高截割部调高过程的稳定性。

Similar content being viewed by others

References

DOLIPSKI M, JASZCZUK M, CHELUSZKA P. Designing of new energy-saving cutting drums of longwall shearers [J]. Australasian Institute of Mining and Metallurgy Publication Series, 2015, 1: 331–340.

LI Li, NI Song. Shearer gearbox fault diagnosis based on improved wavelet denoising pretreatment and EEMD [J]. Journal of Central South University (Science and Technology), 2016, 47(10): 3394–3400. DOI: 10.11817/j.issn. 672–7207.2016.10.016. (in Chinese)

LUO Chen, JIANG Hong, CUI Xin. Experimental study on the axial force of shearer drum cutting coal and rock [J]. Recent Patents on Mechanical Engineering, 2015, 8(1): 70–78. DOI: 10.2174/2212797608666150309235530.

WANG Qi, XIE Xi, CHEN Fei, HAN Zhen, CHEN Chong. Simulative cutting test of the working unit of shearer for surface mines [J]. Journal of China University of Mining and Technology, 1996, 25(4): 12–16. (in Chinese)

WU P, ZENG J, DAI H. Dynamic response analysis of railway passenger car with flexible carbody model based on the semi-active suspensions [J]. Vehicle System Dynamics, 2004, 41: 774–783.

EBRAHIMI S, EBERHARD P. Rigid-elastic modeling of gear wheels in multibody systems [J]. Multibody System Dynamics, 2006, 16(1): 55–71. DOI: 10.1007/s11044-006–9021-7.

JIAO Li, LI Xiao, YAO Ji. Dynamics analysis of double-drum shearer and mechanical model establishment [J]. Journal of Liaoning Technical University, 2007, 26(4): 602–603. DOI: 1008–0562(2007)04-0602-02. (in Chinese)

BALCI C, BILGIN N. Correlative study of linear small and full-scale rock cutting tests to select mechanized excavation machines [J]. International Journal of Rock Mechanics & Mining Sciences, 2007, 44(3): 468–476. DOI: 10.1016/j.ijrmms.2006.09.001.

DU Chang, LIU Song, CUI Xin. Study on pick arrangement of shearer drum based on load fluctuation [J]. Journal of China University of Mining and Technology, 2008, 18(2): 305–310. DOI: 10.1016/S1006-1266(08)60065-6.

ZHAO Li, MA Yong. Reliability research on shearer cutting unit based on multi-body dynamics [J]. Journal of the China Coal Society, 2009, 34(9): 1271–1275. DOI: 10.13225/j.cnki.jccs.2009.09.015. (in Chinese)

ZHAO Li, WANG Cheng. Modeling and dynamic simulation of shearer cutting unit [J]. Journal of Engineering Design, 2010, 17(2): 119–23. (in Chinese)

WANG Zhong, XU Zhi, DONG Xiao. Self-adaptive adjustment height of the drum in the shearer based on artificial immune and memory cutting [J]. Journal of the China Coal Society, 2009, 34(10): 1405–1409. DOI: 10.13225/j.cnki.jccs.2009.10.012. (in Chinese)

GERMAY C, DENOËL V, DETOURNAY E. Multiple mode analysis of the self-excited vibrations of rotary drilling systems [J]. Journal of Sound and Vibration, 2009, 325(1): 362–381. DOI: 10.1016/j.jsv.2009.03.017.

PRATHEEPA B. Modeling and simulation of automobile suspension system [J]. Frontiers in Automobile and Mechanical Engineering, 2010, 43(2): 377–382. DOI: 10.1109/FAME.2010.5714866.

SAHEBKAR S, GHAZAVI M, KHADEM S, GHAYESH M. Nonlinear vibration analysis of an axially moving drillstring system with time dependent axial load axial velocity in inclined well [J]. Mechanism and Machine Theory, 2011, 46(5): 743–760. DOI: 10.1016/j.mechmachtheory.2010.12. 003.

GUO Wei, ZHU Ning, ZHAO Shuan. A method of calculation for the shearer drum cutting path [M]//Informatics in Control, Automation and Robotics. Berlin Heidelberg: Springer, 2011: 389–396. DOI: 10.1007/978-3-642–25899-2_52.

YANG Dao, LI Jian, WANG Yan, JIANG Hong. Research on vibration and deflection for drilling tools of coal auger [J]. Journal of Vibro Engineering, 2017, 19(7): 4882–4897. DOI: https://doi.org/10.21595/jve.2017. 18581

FU Lin, DU Chang, LI Jian, YANG Dao. Structure and parameter analysis of auger miner’s coal plough [J]. Journal of Central South University (Science and Technology), 2017, 48(3): 675–683. DOI: 10.11817/j.issn.1672-7207.2017.03.016. (in Chinese)

ZHAO Shuan, GUO Wei. An EMD based simulation of the drum resistance torque spectrum of a shearer [C]//IEEE International Conference on Computer Science and Automation Engineering. IEEE, 2012, 3: 367–371. DOI: 10.1109/CSAE.2012.6272974.

DING Hua, YANG Zhao. Method and system of shearer cutting unit modern design oriented to KBE [J]. Journal of the China Coal Society, 2012, 37(10): 765–1770. DOI: 10.13225/j.cnki.jccs.2012.10.028. (in Chinese)

CHENG Chun, LI Shun, WANG Yong, JIANG Xing. Performance analysis of high-static-low-dynamic stiffness vibration isolator with time-delayed displacement feedback [J]. Journal of Central South University, 2017, 24(10): 2294–2305. DOI: https://doi.org/10.1007/s11771-017–3641-3.

LI Jian, GUO Hui. Vibration characteristics of shearer cutting unit based on multi-body dynamics [J]. Electronic Journal of Geotechnical Engineering, 2014, 19(4): 3195–3208.

WANG Yong, SUN Dong, LIU Chang. Study on characteristics of external load of transmission system for cutting unit of shearer under multiple load cases [J]. Computer Modelling and New Technologies, 2014, 18(12): 326–330.

GAO Kui, DU Chang, LIU Song, FU Lin. Analysis on significance of the factors influencing on shearer drum cutting performance [J]. International Journal of Oil, Gas and Coal Technology, 2014, 7(4): 386–98. DOI: 10.1504/IJOGCT.2014.062170.

YANG Dao, LI Jian, WANG Li, GAO Kui, TANG You, WANG Yan. Experimental and theoretical design for decreasing wear in conical picks in rotation-drilling cutting process [J]. International Journal of Advanced Manufacturing Technology, 2015, 77(9): 1571–1579. DOI: 10.1007/s00170-014-6472-5.

YANG Dao, LI Jian, DU Chang, LIU Song, ZHENG Ke, JIANG Hong. Wear performance of conical pick in rotary-drilling cutting process [J]. Electronic Journal of Geotechnical Engineering, 2015, 20(8): 2031–2040.

YANG Dao, LI Jian, ZHENG Ke, JIANG Hong, XU Han, LIU Song. High-hardness alloy substituted by low hardness during drilling and cutting experiments of conical pick [J]. International Journal of Rock Mechanics and Mining Sciences, 2017, 95: 73–78. DOI: 10.1016/j.ijrmms.2017.04.006.

DENG Jian, LV Gang, LI Guo, ZHANG Guo. Vertical sectorization using beam steering in cellular communication systems [C]//IEEE/CIC International Conference on Communications in China-Workshops. IEEE, 2014: 21–25. DOI: 10.1109/ICCChinaW. 2014.7107860.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(BK20160250) supported by the Natural Science Foundation of Jiangsu Province, China; Project(17XLR028) supported by the Natural Science Foundation of Jiangsu Normal University, China

Rights and permissions

About this article

Cite this article

Yang, Dl., Li, Jp., Wang, Yx. et al. Analysis on vertical steering vibration of drum shearer cutting part. J. Cent. South Univ. 25, 2722–2732 (2018). https://doi.org/10.1007/s11771-018-3949-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3949-7