Abstract

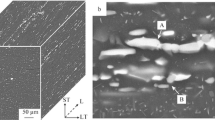

The microstructural evolution of 2026 aluminum alloy during homogenization treatment was investigated by optical microscopy (OM), scanning electron microscopy (SEM), energy dispersive X-ray spectrometry (EDS), differential scanning calorimetry (DSC) and X-ray diffraction (XRD). The results show that severe dendritic segregation exists in the as-cast 2026 alloy and the main secondary phases at grain boundary are S (Al2CuMg) and θ (Al2Cu) phases. Elements Cu, Mg and Mn distribute unevenly from grain boundary to the inside of as-cast alloy. With the increase of homogenization temperature or the prolongation of holding time, the residual phases gradually dissolve into the matrix α(Al) and all the elements become more homogenized. According to the results of microstructural evolution, differential scanning calorimetry and X-ray diffraction, the optimum homogenization parameter is at 490 °C for 24 h, which is consistent with the result of homogenization kinetic analysis.

摘要

采用金相分析、扫描电镜、能谱分析、差示扫描量热法以及X 射线衍射分析等手段,研究均匀 化过程中2026 铝合金微观组织的演变。结果表明:在2026 合金铸态组织中,出现严重的枝晶偏析现 象,晶界处的第二相主要是S 相(Al2CuMg)和θ 相(Al2Cu),元素Cu、Mg 和Mn 在晶内及晶界分布不 均匀。在均匀化过程中,随着均匀化温度的升高或均匀化时间的延长,残留相逐渐溶入基体α (Al), 元素分布逐渐均匀。综合考虑显微组织演变、差示扫描量热分析和X 射线衍射分析等,最佳均匀化制 度为490 °C,24 h,与均匀化动力学分析结果相符合。

Similar content being viewed by others

References

LI Li, LI Hui-zhong, LIANG Xiao-peng, HUANG Lan, HONG Tao. Flow stress behavior of high-purity Al-Cu-Mg alloy and microstructure evolution [J]. Journal of Central South University, 2015, 22(3): 815–820.

WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems [J]. Acta Materialia, 2003, 51(19): 5775–5799.

LIU J Z, YANG S S, WANG S B, CHEN J H, WU C L. The influence of Cu/Mg atomic ratios on precipitation scenarios and mechanical properties of Al–Cu–Mg alloys [J]. Journal of Alloys & Compounds, 2014, 613(7): 139–142.

STYLES M J, HUTCHINSON C R, CHEN Y, DESCHAMPS A, BASTOW T J. The coexistence of two S(Al2CuMg) phases in Al–Cu–Mg alloys [J]. Acta Materialia, 2012, 60(20): 6940–6951.

LIU J, BRAY G H, LUKASAK D A, PAHL R C. Aluminum alloy extrusions having a substantially unrecrystallized structure: US, US6918975 [P]. 2005.

LI J X, ZHAI T, GARRATT M D, BRAY G H. Fourpoint-bend fatigue of AA 2026 aluminum alloys [J]. Metallurgical & Materials Transactions A, 2005, 36(9): 2529–2539.

LAM D F, MENZEMER C C, SRIVATSAN T S. A study to evaluate and understand the response of aluminum alloy 2026 subjected to tensile deformation [J]. Materials & Design, 2010, 31(1): 166–175.

LIU Can, ZHANG Hui, JIANG Fu-lin. Characterization of dynamic microstructure evolution during hot deformation of Al–4.10Cu–1.42Mg–0.57Mn–0.12Zr alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3477–3485.

LIU Xiao-yan, PAN Qing-lin, FAN Xi, HE Yun-bin, LI Wen-bin, LIANG Wen-jie. Microstructural evolution of Al–Cu–Mg–Ag alloy during homogenization [J]. Journal of Alloys & Compounds, 2009, 484: 790–794.

CONG Fu-guan, ZHAO Gang, JIANG Feng, TIAN Ni, LI Rui-feng. Effect of homogenization treatment on microstructure and mechanical properties of DC cast 7X50 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1027–1034.

WANG Hai-jun, XU Ju, KANG Yong-lin, TANG Meng-ou, ZHANG Zhi-feng. Study on inhomogeneous characteristics and optimize homogenization treatment parameter for large size DC ingots of Al–Zn–Mg–Cu alloys [J]. Journal of Alloys & Compounds, 2014, 585(5): 19–24.

LI Bo, PAN Qing-lin, SHI Yun-jia, LI Chen, YIN Zhi-min. Microstructural evolution of Al–Zn–Mg–Zr alloy with trace amount of Sc during homogenization treatment [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3568–3574.

JIANG Hai-chun, YE Ling-ying, ZHANG Xin-ming, GU Gang, ZHANG Pan, WU Yu-long. Intermetallic phase evolution of 5059 aluminum alloy during homogenization [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3553–3560.

LI Hong-ying, SU Xiong-jie, YIN Hao, HUANG De-sheng. Microstructural evolution during homogenization of Al-Cu-Li-Mn-Zr-Ti alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2543–2550.

SHI Yun-jia, PAN Qing-lin, LI Meng-jia, LIU Zhi-ming, HUANG Zhi-qi. Microstructural evolution during homogenization of DC cast 7085 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3560–3568.

DENG Ying, YIN Zhi-min, CONG Fu-guan. Intermetallic phase evolution of 7050 aluminum alloy during homogenization [J]. Intermetallics, 2012, 26(7): 114–121.

LIU Qing, ZHU Rui-hua, LI Jin-fen, CHEN Yong-lai, ZHANG Xu-hu, ZHANG Long, ZHENG Zi-qiao. Microstructural evolution of Mg, Ag and Zn micro-alloyed Al-Cu-Li alloy during homogenization [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(3): 607–619.

GARRATT M D, BRAY G H. The grain boundary geometry for optimum resistance to growth of short fatigue cracks in high strength Al-alloys [J]. International Journal of Fatigue, 2005, 27(s10–12): 1202–1209.

ZHANG Hui, CHEN Rong, HUANG Xu-dong, CHEN Jiang-hua. Microstructural evolution of 2026 aluminum alloy during hot compression and subsequent heat treatment [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(5): 955–961.

HUANG Xu-dong, ZHANG Hui, HAN Yi, WU Wen-xiang, CHEN Jiang-hua. Hot deformation behavior of 2026 aluminum alloy during compression at elevated temperature [J]. Materials Science & Engineering A, 2010, 527(3): 485–490.

ZHANG J, HUANG Y N, MAO C, PENG P. Structural, elastic and electronic properties of θ(Al2Cu) and S(Al2CuMg) strengthening precipitates in Al–Cu–Mg series alloys: First-principles calculations [J]. Solid State Communications, 2012, 152(23): 2100–2104.

MONDOLFO L F. Aluminum alloys: Structure and properties [J]. Materials Science in Semiconductor Processing, 1976, 31(11): 651–657.

SHEWMON P G. Diffusion in solids [M]. New York: McGraw-Hill, 1963: 61.

LI Wen-bin, PAN Qing-lin, XIAO Yan-ping, HE Yun-bin, LIU Xiao-yan. Microstructural evolution of ultra-high strength Al-Zn-Cu-Mg-Zr alloy containing Sc during homogenization [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(10): 2127–2133.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2016B090931001) supported by Science and Technology Research and Development Program of Guangdong Province, China

Rights and permissions

About this article

Cite this article

Jiang, Db., Pan, Ql., Huang, Zq. et al. Microstructural evolution of 2026 aluminum alloy during homogenization. J. Cent. South Univ. 25, 490–498 (2018). https://doi.org/10.1007/s11771-018-3753-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3753-4

Keywords

- 2026 aluminum alloy

- dendritic segregation

- homogenization

- microstructure evolution

- homogenization kinetics