Abstract

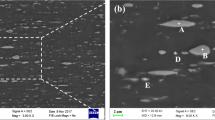

With the aid of scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS), X-ray diffraction (XRD), differential scanning calorimetry (DSC) analysis and electron backscatter diffraction (EBSD), the microstructure of the alloy in as-extruded state and various solution-treated states was investigated. The results indicate that second phase of the as-extruded 7136 aluminum alloy mainly consists of Mg(Zn, Cu, Al)2 and Fe-rich phases. The Mg(Zn, Cu, Al)2 phase directly dissolves into the matrix during solution treatment with various solution temperatures. After solution treated at 475 °C for 1 h, Mg(Zn, Cu, Al)2 phases are dissolved into the matrix, while Fe-rich phases still exist. Fe-rich phases could not dissolve into the matrix by prolonging solution time. The mechanical property test and EBSD observation show that two-stage solution treatment makes no significant improvement in mechanical properties and recrystallization of the alloy. The optimized solution treatment parameter is chosen as 475 °C/1 h.

Similar content being viewed by others

References

Dursun T, Soutis C. Recent developments in advanced aircraft aluminium alloys. Mater Des. 2014;56:862.

Wang X, Guo M, Cao L. Effect of heating rate on mechanical property, microstructure and texture evolution of Al–Mg–Si–Cu alloy during solution treatment. Mater Sci Eng A. 2015;621:8.

Mazibuko NE, Curle UA. Effect of solution heat treatment time on a rheocast Al–Zn–Mg–Cu alloy. Mater Sci Forum. 2011;690:15.

Liu Y, Jiang D, Xie W. Solidification phases and their evolution during homogenization of a DC cast Al–8.35Zn–2.5Mg–2.25Cu alloy. Mater Charact. 2014;93:173.

Fan X, Jiang D, Meng Q. The microstructural evolution of an Al–Zn–Mg–Cu alloy during homogenization. Mater Lett. 2011;60(12):1475.

Liu Y, Jiang D, Li B. Heating aging behavior of Al–8.35Zn–2.5Mg–2.25Cu alloy. Mater Des. 2014;60:116.

Rometsch PA, Zhang Y, Knight S. Heat treatment of 7xxx series aluminium alloys—some recent developments. Trans Nonferrous Met Soc China. 2014;24(7):2003.

Yang XB, Chen JH, Liu JZ. A high-strength AlZnMg alloy hardened by the T-phase precipitates. J Alloys Compd. 2014;610:69.

Marlaud T, Deschamps A, Bley F. Influence of alloy composition and heat treatment on precipitate composition in Al–Zn–Mg–Cu alloys. Acta Mater. 2010;58(1):248.

Reda Y, Abdel-Karim R, Elmahallawi I. Improvements in mechanical and stress corrosion cracking properties in Al-alloy 7075 via retrogression and reaging. Mater Sci Eng A. 2008;485(1):468.

Chen SY, Chen KH, Peng GS. Effect of quenching rate on microstructure and stress corrosion cracking of 7085 aluminum alloy. Trans Nonferrous Met Soc China. 2012;22(1):47.

Wang HJ, Xu J, Kang YL. Study on inhomogeneous characteristics and optimize homogenization treatment parameter for large size DC ingots of Al–Zn–Mg–Cu alloys. J Alloys Compd. 2014;585:19.

Lin JT, Zhang YA, Li XW. Thermodynamic calculation of high zinc-containing Al–Zn–Mg–Cu alloy. Trans Nonferrous Met Soc China. 2014;24(5):1481.

AMS4415A. Aluminum alloy extrusions, 8.9Zn–2.2Cu–2.2Mg–0.15Zr (7136-T76511, -T76510) solution heat treated, stress-relieved, straightened, and overaged. SAE Technical Paper, 2008.

Miller WS, Zhuang L, Bottema J. Recent development in aluminium alloys for the automotive industry. Mater Sci Eng A. 2000;280(1):37.

Han NM, Zhang XM, Liu SD. Effect of solution treatment on the strength and fracture toughness of aluminum alloy 7050. J Alloys Compd. 2011;509(10):4138.

Wang GS, Zhao ZH, Zhang YH. Effects of solution treatment on microstructure and mechanical properties of Al–9.0Zn–2.8Mg–2.5Cu–0.12Zr–0.0Sc alloy. Trans Nonferrous Met Soc China. 2013;23(9):2537.

Fang HC, Chen KH, Chen X. Effect of Cr, Yb and Zr additions on localized corrosion of Al–Zn–Mg–Cu alloy. Corros Sci. 2009;51(12):2872.

Deng YL, Wan L, Zhang Y. Evolution of microstructures and textures of 7050 Al alloy hot-rolled plate during staged solution heat-treatments. J Alloys Compd. 2010;498(1):88.

Xu DK, Rometsch PA, Birbilis N. Improved solution treatment for an as-rolled Al–Zn–Mg–Cu alloy. Part I. Characterisation of constituent particles and overheating. Mater Sci Eng A. 2012;534:234.

Xu DK, Rometsch PA, Birbilis N. Improved solution treatment for an as-rolled Al–Zn–Mg–Cu alloy. Part II. Microstructure and mechanical properties. Mater Sci Eng A. 2012;534:244.

Luo J, Li MQ, Ma DW. Microstructure and mechanical properties of 7A09 aluminium alloy after isothermal compression and solution treatment. J Mater Process Technol. 2012;212(5):1039.

Andean N, Taheri AK. Physically based material model for evolution of stress–strain behavior of heat treatable aluminum alloys during solution heat treatment. Mater Des. 2010;31(1):433.

Askari-Paykani M, Meratian M, Shayan M. Effects of heat treatment parameters on misconstruction changes and corrosion behavior of Al 7075 alclad alloy. Anti Corros Methods Meter. 2012;59(5):231.

Xu DK, Birbilis N, Rometsch PA. Effect of S-phase dissolution on the corrosion and stress corrosion cracking of an as-rolled Al–Zn–Mg–Cu alloy. Corrosion. 2012;68(3):1.

Yang XB, Chen JH, Liu JZ. Spherical constituent particles formed by a multistage solution treatment in Al–Zn–Mg–Cu alloys. Mater Charact. 2013;83:79.

Li P, Xiong B, Zhang Y. Temperature variation and solution treatment of high strength AA7050. Trans Nonferrous Met Soc China. 2012;22(3):546.

Chen K, Liu H, Zhang Z. The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments. J Mater Process Technol. 2003;142(1):190.

Li G, Zhao N, Liu T. Effect of Sc/Zr ratio on the microstructure and mechanical properties of new type of Al–Zn–Mg–Sc–Zr alloys. Mater Sci Eng A. 2014;617:219.

Anjabin N, Taheri AK. Physically based material model for evolution of stress–strain behavior of heat treatable aluminum alloys during solution heat treatment. Mater Des. 2010;31(1):433.

Li ZH, Zhang YA, Xiong BQ, Fan YQ, Li XW, Liu HW, Wang F, Zhu RR. Investigation on microstructure in as-cast aluminum alloy 7136 and its evolution during homogenization. In: 8 Pacific Rim International Congress on Advanced Materials and Processing, Waikoloa; 2013. 1299.

Acknowledgements

This study was financially supported by the National Key Research and Development Program of China (No. 2016YFB0300903), the National Program on Key Basic Research Project of China (No. 2012CB619504) and the National Natural Science Foundation of China (No. 51274046).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, YQ., Wen, K., Li, ZH. et al. Microstructure of as-extruded 7136 aluminum alloy and its evolution during solution treatment. Rare Met. 36, 256–262 (2017). https://doi.org/10.1007/s12598-017-0876-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0876-y