Abstract

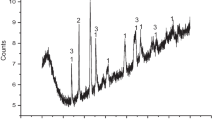

To develop an effective process for titanium powders production, a calciothermic reduction process of pigment titanium dioxide (w(TiO2)>98%), based on the preform reduction process (PRP), was investigated by means of XRD, SEM and EDS. In this process, the mixture of TiO2 powder and CaCl2 was pressed into pieces as feed preform and was reduced by calcium vapor. Titanium powders was recovered after leaching from the reduced preform with hydrochloric acid and deionized water. The results indicate when the mass ratio of CaCl2 to TiO2 is about 1:4 and at a constant temperature of 1 273 K for 6 h in vacuum furnace, titanium powders with 99.55% purity by EDS analysis and irregular shape (8–15 μm in particle size) are obtained.

Similar content being viewed by others

References

CHEN Tai-wu. Analysis and control of high temperature sintering in titanium sponge production by magnesium reduction method [J]. Titanium Industry Progress, 2009, 26(2): 34–36. (in Chinese)

KROLL W J. The production of ductile titanium [J]. Transactions of Electrochemical Society, 1940, 78: 35–47.

DU Ji-hong. Research progress of titanium production technology [J]. Rare Metal Materials and Engineering, 2008, 37(10): 1872–1875.

OGASAWARA T. Progress of the titanium production technology in Japan and future prospects of the field [J]. The Japan Titanium Society, 2005, 53: 103–108.

ZHENG Hai-yan, TORU H. OKABE. Recovery of titanium metal scrap by utilizing chloride wastes [J]. Journal of Alloys and Compounds, 2008, 461: 459–466.

TOMONARI T. Titanium industry—its growing steps and future possibility [R]. Tokyo, Japan: The Japan Titanium Soc, 2000.

SCHWANDTC. ALEXANDER D T L. FRAY D J. The electro-deoxidation of porous titanium dioxide precursors in molten calcium chloride under cathodic potential control [J]. Electrochimica Acta, 2009, 54: 3819–3829.

JIANG K, HU X H, MA M S. Perovskitization-assisted electrochemical reduction of solid TiO2 in molten CaCl2 [J]. Angew Chem Int Ed, 2006, 45: 428–446.

LI Wei, WANG Ying, TANG Ren-heng, XIAO Fang-ming. Reseach development of preparation of titanium by the FFC cambridge process [J]. Materials Research and Application, 2010, 4(4): 555–558. (in Chinese)

MOXSON V S, SENKOV O N, FROES F H. Innovations in titanium powder processing [J]. JOM, 2000, 52(5): 24–26.

ONO K, SUZUKI R O. A new concept for producing Ti sponge: Calciothermic reduction [J]. JOM, 2002, 54(2): 59–61.

ZHENG Hai-yan, LU Jin-wen, SHEN Feng-man. New technologies on direct production of metallic titanium from TiO2 [J]. The Chinese Journal of Process Engineering, 2009, 9(1): 448–451. (in Chinese)

OKABE T H, SADOWAY D R. Metallothermic reduction as an electronically mediated reaction [J]. Journal of Materials Research, 1998, 13: 3372–3377.

OKABE T H, TAKASHI O, YOSHITAKA M. Titanium powder production by perform reduction process (PRP) [J]. Journal of Alloy sand Compounds, 2004, 364: 156–163.

XU Bao-qiang, YANG bin, WAN He-li, SEN Wei. Preparing titanium powders by calcium vapor reduction process of titanium dioxide [C]// Proceedings of the 140th Annual Meeting & Exhibition. New York: John Wiley and Sons Incorporation, 2011: 501–508.

OKABE T H, NAKAMURA M, OISHI T, ONUS K. Electrochemical deoxidation of titanium [J]. Metallurgical Transactions B, 1993, 24: 449–455.

HUA Yi-xin. Kinetics of metallurgical process [M]. Beijing: Metallurgy Industry Press, 2004: 84–86. (in Chinese)

OKABE T H, SUZUKI R O, OISHI T, ONO K. Thermodynamic properties of dilute titanium-oxygen solid solution in beta phase [J]. Mat Trans, 1991, 32(5): 485–488.

OSAMU T, TORU H. Okabe. Fundamental study on synthesis and enrichment of titanium subchloride [J]. Journal of Alloys and Compounds, 2008, 457: 376–383.

LIU Mei-feng, LU Shi-gang, KAN Su-rong, LI Guo-xun. Effect of electrolysis voltage on electrochemical reduction of titanium oxide to titanium in molten calcium chloride [J]. Rare Metals, 2007, 26(6): 547–551.

GUO Shi-ju. Powder sintering theory [M]. Beijing: Metallurgy Industry Press, 1998: 11–21. (in Chinese)

DU Ji-hong, XI Zheng-ping, LI Qing-yu, XU Qian, TANG Yong, LI Zheng-xian. Effect of TiO2 cathode performance on preparation of Ti by electro-deoxidation [J]. Trans Nonferrous Met Soc China, 2007, 17: 514–521.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51004058) supported by the National Natural Science Foundation of China; Project(2011FB039) supported by the Natural Science Foundation of Yunnan Province, China

Rights and permissions

About this article

Cite this article

Wan, Hl., Xu, Bq., Dai, Yn. et al. Preparation of titanium powders by calciothermic reduction of titanium dioxide. J. Cent. South Univ. 19, 2434–2439 (2012). https://doi.org/10.1007/s11771-012-1293-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-012-1293-x