Abstract

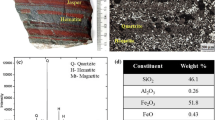

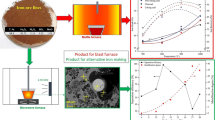

Chromium ore fines containing coal (COFCC) can be rapidly heated by microwave to conduct the voluminal reduction, which lays a foundation of getting sponge ferrochromium powders with a lower content of C. Under the conditions of COFCC with n(O):n(C) (molar ratio) as 1.00:0.84 and n(SiO2):n(CaO) as 1.00:0.39, the samples were heated by 10 kW microwave power to reach the given temperatures and held for different times respectively. The results show that the low-C-Cr ferrochromium metal phase in the reduced materials forms before the high-C-Cr ferrochromium metal phase does. With increasing temperature the C content of ferrochromium metals is in a positive correlation with the content of Cr. The C content of ferrochromium metal in reduced materials is 0–10.07% with an average value of 4.68%. With the increase of holding time the Cr content in ferrochromium metals is in a negative correlation with the content of C, while the content of Fe changes in the contrary way. In the microwave field the kinetic conditions of carburization are closely related with the temperature of microwave heating, holding time and carbon fitting ratio.

Similar content being viewed by others

References

LEŠKO A, NAVARA E. Microstructural characterization of high-carbon ferrochromium [J]. Materials Characterization, 1996, 36(4): 349–356.

GEMINIANI A, GRANDE M A. Chrome carbide investigated [J]. Metal Powder Report, 2003, 58(3): 23–24.

DETROYE M, RENIERS F, BUESS-HERMAN C, VEREECKEN J. AES-XPS study of chromium carbides and chromium iron carbides [J]. Applied Surface Science, 1999, 144(4): 78–82.

AKYÜZLÜ M, ERIC R H. Slag-metal equilibrium in the smelting of high-carbon ferrochromium [J]. Journal of the South African Institute of Mining and Metallurgy, 1992, 92(4): 101–110.

ZHU De-qing, LI Jian, PAN Jian, HE Ao-ping. Sintering behaviours of chromite fines and the consolidation mechanism [J]. International Journal of Mineral Processing, 2008, 86(1): 58–67.

HONKANIEMI M, KROGERUS H, DAAVITTILA J, OIKARINEN P. The importance of chromite pre-treatment in the production of ferrochromium [C]// Sixth International Ferro Alloys Congress. Cape Town, 1992, 1: 79–86.

BASSON J, CURR T R, GERICKE W A. South Africa’s ferroalloys industry-present status and future outlook [C]// The Eleventh International Ferro Alloys Congress. New Delhi, 2007, 1: 3–24.

LEOT’EV L I, ZHUCHKOV V I, SMIRNOV L A, DASHEVSKII V Y. Global and Russian ferroalloy production [J]. Steel in Translation, 2007, 37(3): 283–287.

XUE Zheng-liang, HU Hui-jun, ZHANG You-ping, TING Xiu-mei, CUI Hui-jun, LIU Jin-ying. High temperature reduction properties of synthetic chromite by carbon [J]. Journal of Wuhan University of Science and Technology: Natural Science Edition, 2004, 27(1): 1–3. (in Chinese)

HIROSHI G. The reduction behavior of synthetic chromites by carbon [J]. Transactions of the Iron and Steel Institute of Japan, 1980, 20: 154–162.

LIN Q, LIU R, CHEN N. Kinetics of direct reduction of chrome iron ore [J]. Journal of Thermal Analysis and Calorimetry, 1999, 58(2): 317–322.

XUE Zheng-liang, HU Hui-jun, ZHANG You-ping, LI Zheng-bang, ZHOU Yu-sheng. Condense behaviour of metal phase in synthetic chromite briquette by carbon during high temperature reduction [J]. Ferro-Alloys, 2004(5): 1–5. (in Chinese)

SOYKAN O, ERIC R H, KING R P. The reduction mechanism o f a natural chromite at 1 416 °C [J]. Metallurgical and Materials Transactions B, 1991, 22(1): 53–63.

NIAYESH M J, DIPPENAR R J. The solid state reduction of chromite [C]// Sixth International Ferro Alloys Congress. Cape Town, 1992, 1: 57–63.

ZHANG You-ping, LI Zheng-bang, XUE Zheng-liang. Application technology of chromite ore fines for producing stainless steel master alloy [J]. Special Steel, 2003, 24(1): 29–32. (in Chinese)

JIANG Guo-chang, XU Jiang-lun, XU Kuang-di. A basic study on reduction process of chrome ore agglomerate [J]. Ferro-Alloys, 1989(5): 23–30. (in Chinese)

XU Rong-jun, NI Rui-ming, ZHANG Sheng-bi, MA Zhong-ting. Research on reduction thermodynamics of carbon-bearing chromite pellets [J]. Sintering and Pelletizing, 1996, 21(3): 1–4. (in Chinese)

CHAKRABORTY D, RANGANATHAN S, SINHA S N. Investigations on the carbothermic reduction of chromite ores [J]. Metallurgical and Materials Transaction B, 2005, 36(4): 437–444.

GOLDSTEIN J I, MOREN A E. Diffusion modeling of the carburization process [J]. Metallurgical and Materials Transaction A, 1978, 9(11): 1515–1525.

TANG Dian, QIU Yu-lang, CHEN Zai-liang. Carburizing and nitriding of ferrous metals in ancient China [J]. Teat Treatment of Metals, 2002, 27(8): 50–53. (in Chinese)

ZHANG Yao-li, WU Yan. A study on the carburizing velocity [J]. Industrial Heating, 2000(3): 40–42. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(50474083) supported by the National Natural Science Foundation of China; Project supported by the Baoshan Iron & Steel Co. Ltd. of China

Rights and permissions

About this article

Cite this article

Chen, J., Zhao, J., Zhang, M. et al. Carburization of ferrochromium metals in chromium ore fines containing coal during voluminal reduction by microwave heating. J. Cent. South Univ. Technol. 16, 43–48 (2009). https://doi.org/10.1007/s11771-009-0007-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-009-0007-5